Bone repair material and preparation method thereof

A bone repair and microvascular technology, applied in the fields of prosthesis, tissue regeneration, medical science, etc., can solve the problems of complex procedures, time-consuming, difficult application, etc., and achieve the effect of high biocompatibility, simple preparation method, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

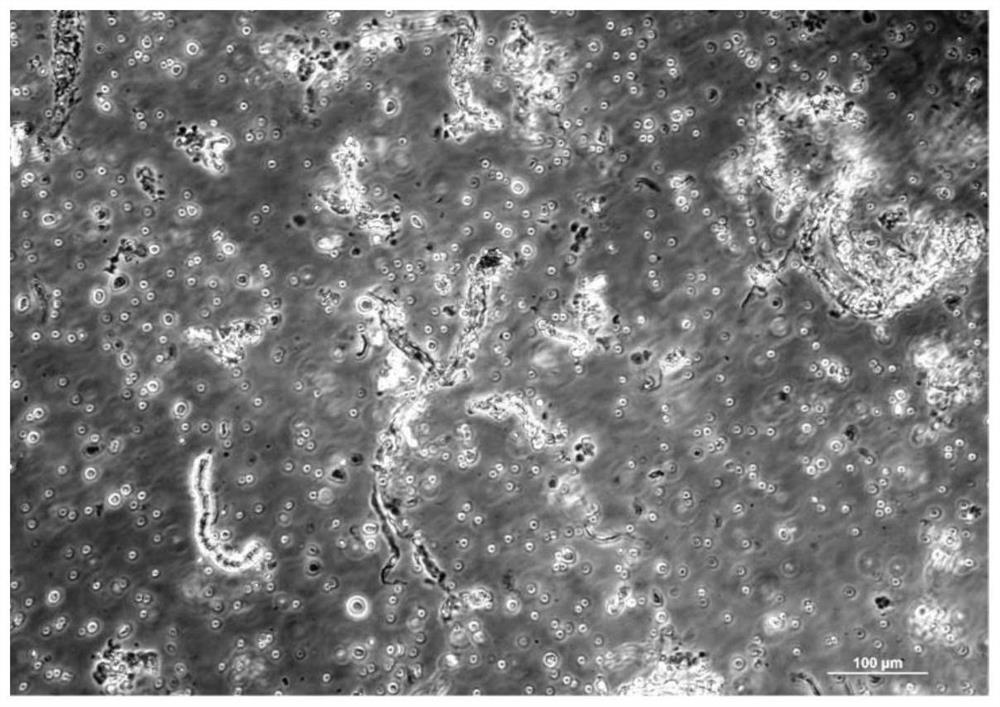

[0040] The present embodiment relates to a preparation method of ad-MVF / GelMA composite hydrogel, comprising the following steps:

[0041] S11, take 10 mL of adipose tissue, chop it mechanically, wash away the blood and other contaminants on the adipose tissue with 0.9% normal saline, and then add twice the volume (20 mL) of 2 mg / mL type I collagenase solution;

[0042] S12, under humidified atmosphere conditions, digest with rapid stirring at 37 °C for 8 min, and add an equal volume (30 mL) of PBS containing 20% FBS to neutralize type I collagenase;

[0043] S13, filter the suspension through a 500 μm filter screen to remove undigested fat mass on the filter screen, centrifuge the filtrate at 10,000 rpm for 5 min, and remove the fat supernatant;

[0044] S14, filter the suspension through a 30 μm filter screen, filter out the remaining impurity cells, wash off the filtrate on the filter screen with 0.9% normal saline, centrifuge at 10,000 rpm for 5 min, remove the supernata...

Embodiment 2

[0050] The present embodiment relates to a preparation method of ad-MVF / HAMA composite hydrogel, comprising the following steps:

[0051] S11, take 5 mL of adipose tissue, chop it mechanically, wash away the blood and other contaminants on the adipose tissue with 0.9% normal saline, and add 1.5 times the volume of 1.5 mg / mL type I collagenase solution;

[0052] S12, under humidified atmospheric conditions, digest with rapid stirring at 37 °C for 10 min, and add an equal volume of PBS containing 20% FBS to neutralize collagenase type I;

[0053] S13, filter the suspension through a 600 μm filter screen to remove undigested fat mass on the filter screen, centrifuge the filtrate at 12,000 rpm for 3 min, and remove the fat supernatant;

[0054] S14, filter the suspension through a 50 μm filter screen, filter out the remaining impurity cells, wash off the filtrate on the filter screen with 0.9% normal saline, centrifuge at 12000 rpm for 3 min, remove the supernatant, and leave th...

Embodiment 3

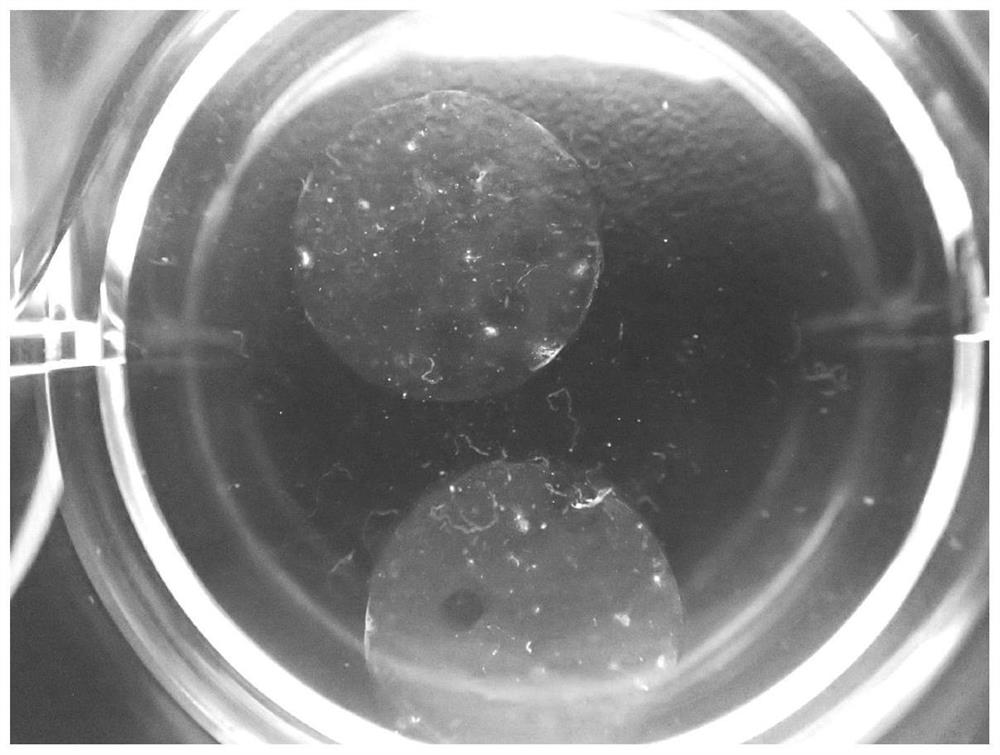

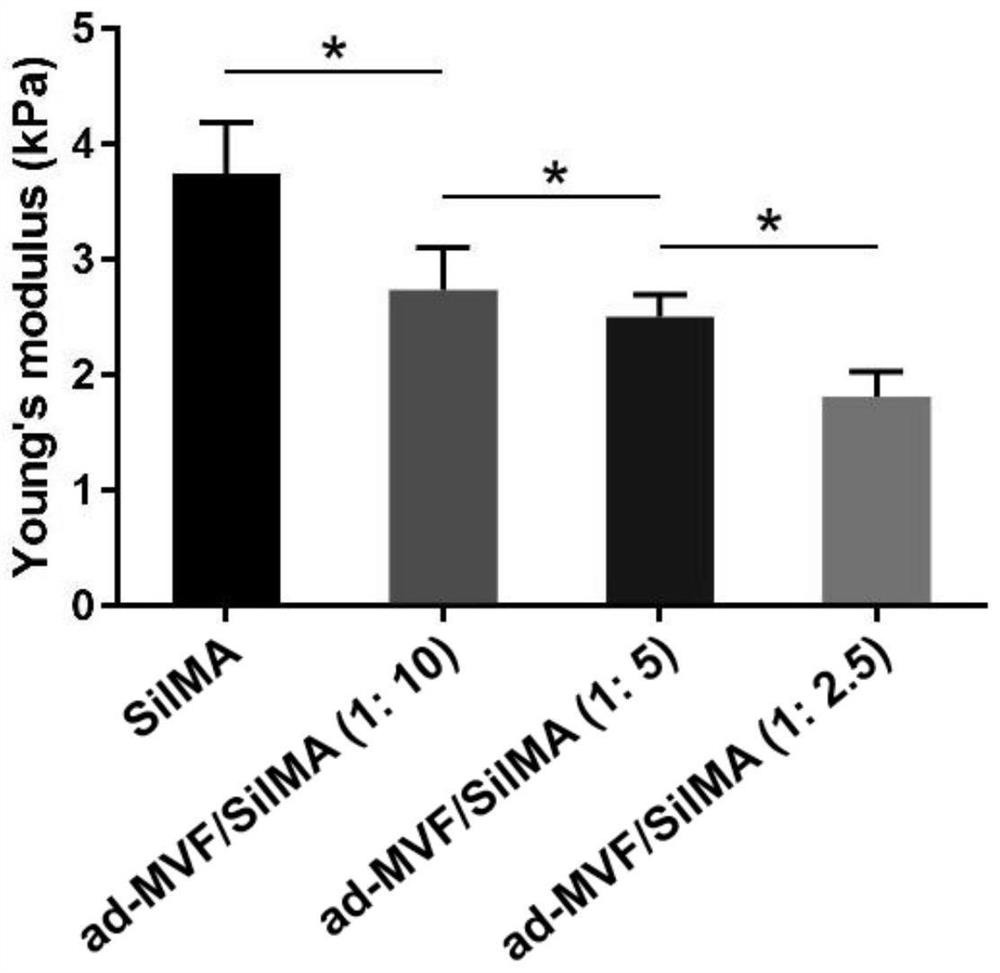

[0058] The present embodiment relates to a preparation method of ad-MVF / SilMA composite hydrogel, comprising the following steps:

[0059] S21, take 2.5 mL of adipose tissue, chop it mechanically, wash away the blood and other contaminants on the adipose tissue with 0.9% normal saline, and add three times the volume of 1 mg / mL type I collagenase solution;

[0060] S22, under humidified atmosphere conditions, digest with rapid stirring at 37 °C for 12 min, and add an equal volume of PBS containing 20% FBS to neutralize collagenase type I;

[0061] S23, filter the suspension through a 450 μm filter screen to remove undigested fat mass on the filter screen, centrifuge the filtrate at 800 rpm for 6 min, and remove the fat supernatant;

[0062] S24, filter the suspension through a 45 μm filter screen, filter out the remaining impurity cells, wash off the filtrate on the filter screen with 0.9% normal saline, centrifuge at 800 rpm for 6 min, remove the supernatant, and leave the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com