TON/MRE double-topological-structure composite molecular sieve and preparation thereof

A composite molecular sieve and topological structure technology, applied in the field of molecular sieves, can solve problems such as poor product reproducibility, difficult control of process conditions, and long process, and achieve the effects of less miscellaneous crystal content, easy control of operating conditions, and simple synthesis methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Dissolve 3.29g of 1,6-hexanediamine in 16ml of distilled water, stir until it becomes clear, then add 1.08g of ammonium fluoride, 0.045g of aluminum sulfate octadecahydrate, 0.13g of potassium hydroxide, stir until it is completely dissolved, then add 0.0053 gZSM-22 seed crystals and 0.0053g ZSM-48 mixed seed crystals were added dropwise with 8 g of silica sol (30%), and after stirring for 0.5 h, a gel mixture with the following molar ratio was formed (silica sol was SiO 2 In terms of Al source, Al 2 O 3 Calculated, the alkali source is OH - meter): silicon source: aluminum source: alkali source: template agent: water: ammonium fluoride = 1: 0.0038: 0.058: 0.7: 30: 0.7.

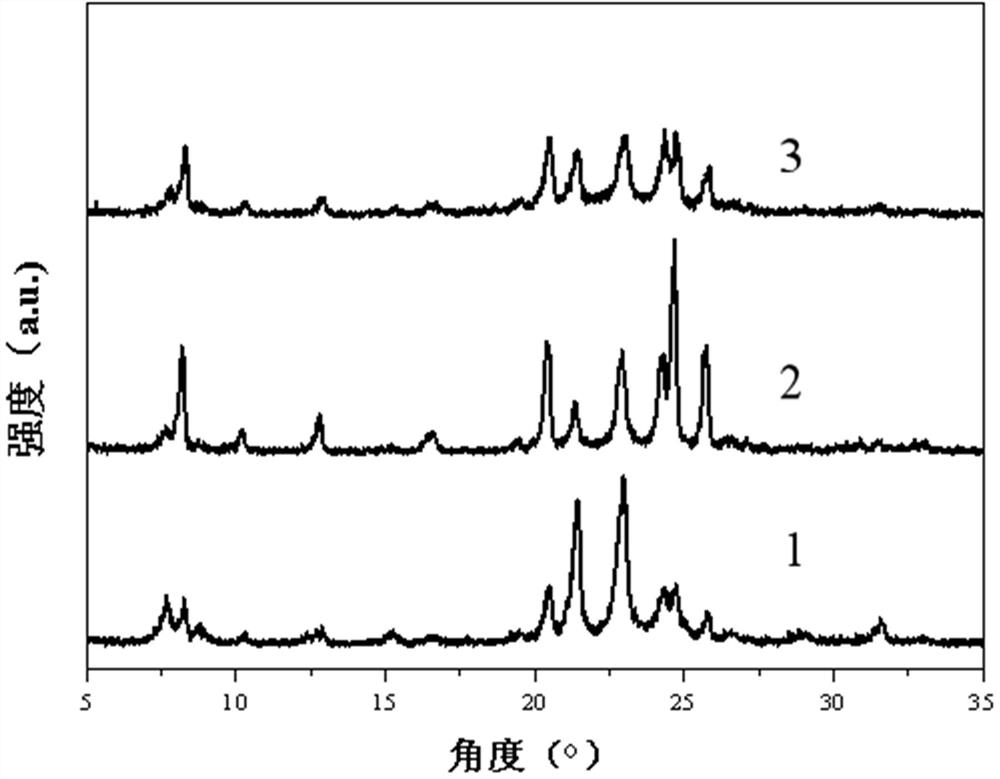

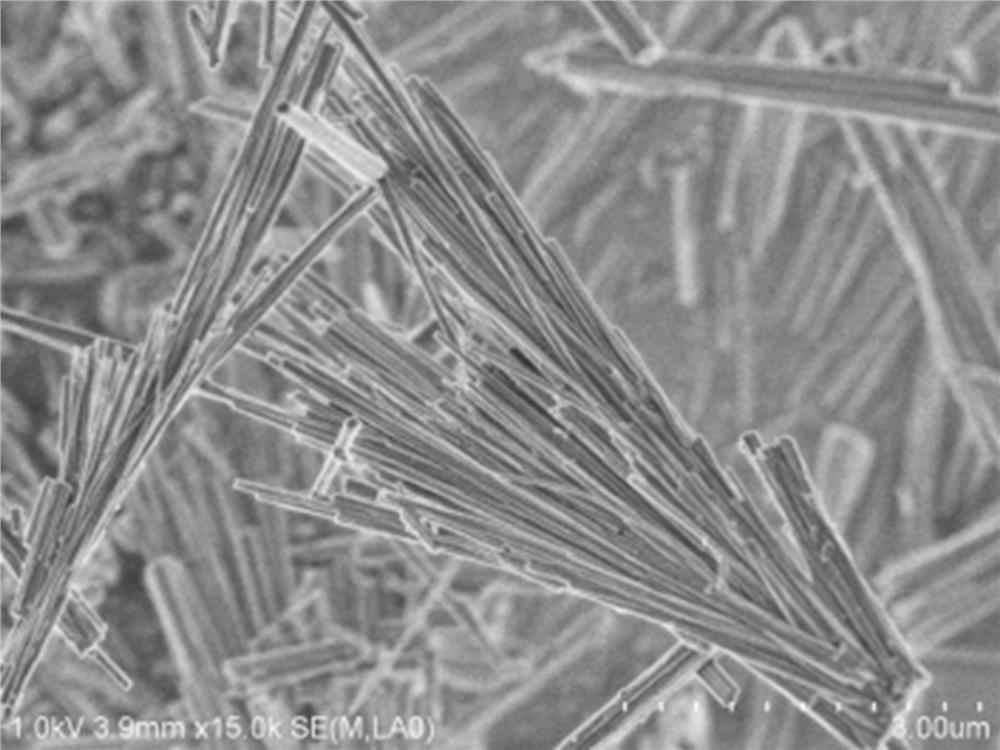

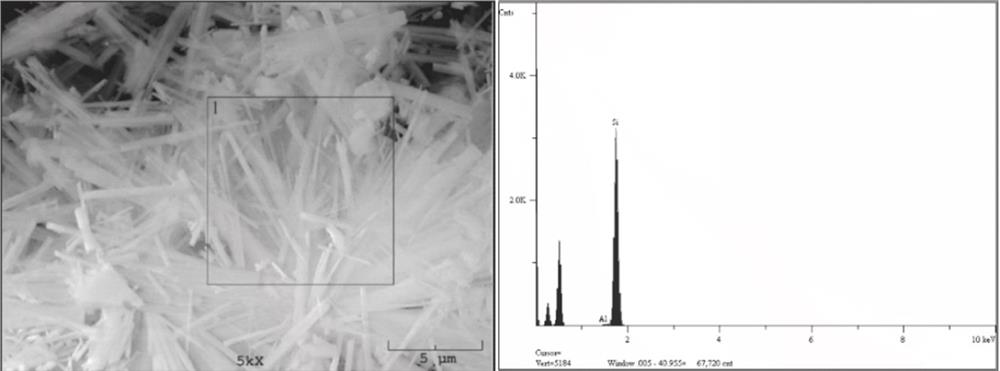

[0025] The gelatinous mixture was put into a stainless steel reaction kettle with a polytetrafluoroethylene lining, placed in an oven at 160°C, and crystallized under autogenous pressure for 2 days. The filtrate of the solid product obtained by washing was neutral, and dried at 70°C for 20h to obtai...

Embodiment 2

[0028] Dissolve 1.65g of 1,6-hexanediamine in 30ml of distilled water, stir until it becomes clear, then add 1.08g of ammonium fluoride, 0.065g of aluminum sulfate octadecahydrate, 0.23g of potassium hydroxide, stir until it is completely dissolved, then add 0.0045 g gZSM-22 seed crystal and 0.0045g ZSM-48 mixed seed crystal, 8g silica sol (40%) was added dropwise, and after stirring for 1 hour, a gel mixture with the following molar ratio was formed (silica sol was SiO 2 The aluminum source is calculated as Al, and the alkali source is calculated as OH - meter): silicon source: aluminum source: alkali source: template agent: water: ammonium fluoride = 1: 0.0045: 0.03: 0.3: 36: 0.5.

[0029] The gelatinous mixture was put into a stainless steel reaction kettle with a Teflon lining, placed in an oven at 180°C, and crystallized for 8 hours under autogenous pressure. After the crystallization was completed, centrifuged and washed with deionized water. The obtained solid product ...

Embodiment 3

[0035] Dissolve 0.35g of 1,6-hexanediamine in 20ml of distilled water, stir until it becomes clear, then add 0.81g of ammonium fluoride, 0.11g of aluminum sulfate octadecahydrate, 0.16g of potassium hydroxide, stir until completely dissolved, then add 0.0040 gZSM-22 seed crystal and 0.0040g ZSM-48 mixed seed crystal, 7g of silica sol (30%) was added dropwise, and after stirring for 1.5h, a gel mixture with the following molar ratio was formed (silica sol is SiO 2 In terms of Al source, Al 2 O 3 Calculated, the alkali source is OH - Calculation): silicon source: aluminum source: alkali source: template agent: water: ammonium fluoride = 1: 0.0047: 0.08: 0.17: 40: 0.62.

[0036] The above gelatinous mixture was put into a stainless steel reaction kettle with a polytetrafluoroethylene lining, placed in an oven at 160 °C, and crystallized under autogenous pressure for 72 hours. The filtrate of the solid product obtained by washing was neutral, and dried at 70°C for 24h to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com