Heavy calcium carbonate composite filler and preparation method thereof

A technology of heavy calcium carbonate and composite fillers, which is applied in the direction of fibrous fillers, chemical instruments and methods, and inorganic pigment treatment. Effect of reducing surface polarity and improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

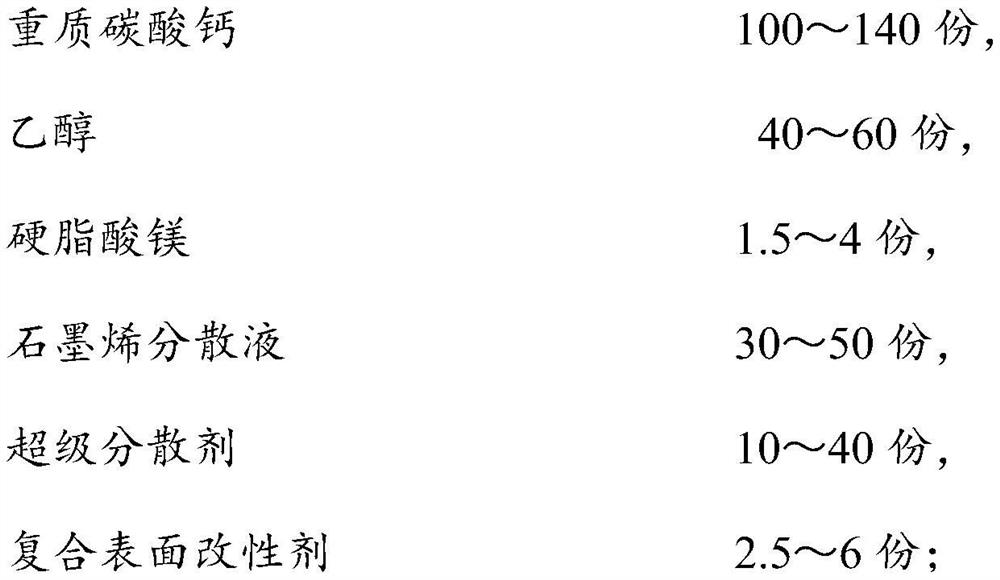

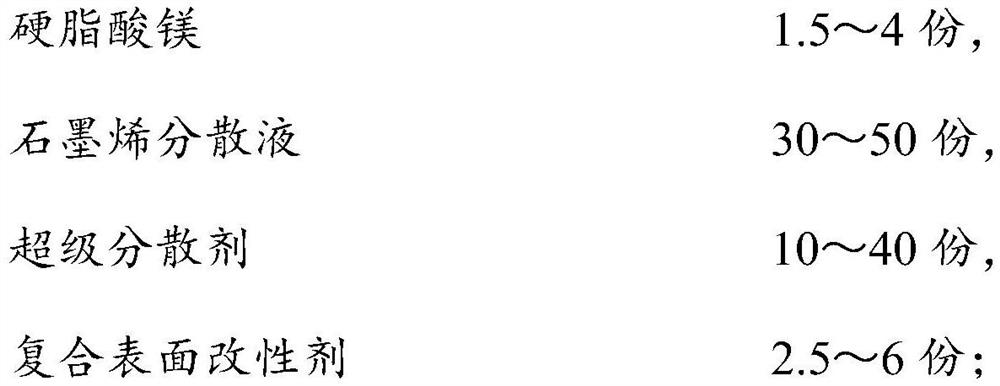

[0031] A heavy calcium carbonate composite filler, comprising the following raw materials in parts by mass: 100 parts of heavy calcium carbonate, 40 parts of ethanol, 1.5 parts of magnesium stearate, 30 parts of graphene dispersion, 10 parts of super dispersant, composite surface 2.5 parts of modifier;

[0032] The preparation method of described ground calcium carbonate composite filler, comprises the following steps:

[0033] Step 1: Take heavy calcium carbonate in parts by mass and add it to the ball milling tank of the vertical stirring ball mill, add ethanol in parts by mass, add zirconia balls, and perform ball milling. Set the stirring speed to 300r / min, and the ball milling time to 20min ;

[0034] Step 2: Control the temperature of the ball mill tank to 80°C by constant temperature circulating water, add the composite surface modifier in parts by mass, and mill for 15 minutes at a stirring speed of 300r / min; add magnesium stearate in parts by mass, continue to 300r / ...

Embodiment 2

[0037] A heavy calcium carbonate composite filler, comprising the following raw materials in parts by mass: 140 parts of heavy calcium carbonate, 60 parts of ethanol, 4 parts of magnesium stearate, 50 parts of graphene dispersion, 40 parts of super dispersant, composite surface 6 parts of modifier;

[0038] The preparation method of described ground calcium carbonate composite filler, comprises the following steps:

[0039]Step 1: Take heavy calcium carbonate in parts by mass and add it to the ball milling tank of the vertical stirring ball mill, add ethanol in parts by mass, add zirconia balls, and perform ball milling. Set the stirring speed to 600r / min, and the ball milling time to 30min ;

[0040] Step 2: Control the temperature of the ball milling tank to 95°C through constant temperature circulating water, add a composite surface modifier in parts by mass, and mill for 30 minutes at a stirring speed of 600r / min; add magnesium stearate in parts by mass, and continue to ...

Embodiment 3

[0043] A heavy calcium carbonate composite filler, comprising the following raw materials in parts by mass: 120 parts of heavy calcium carbonate, 50 parts of ethanol, 3 parts of magnesium stearate, 40 parts of graphene dispersion, 25 parts of super dispersant, composite surface Modifier 4 parts;

[0044] The preparation method of described ground calcium carbonate composite filler, comprises the following steps:

[0045] Step 1: Take heavy calcium carbonate in parts by mass and add it to the ball milling tank of the vertical stirring ball mill, add ethanol in parts by mass, add zirconia balls, and carry out ball milling, set the stirring speed to 400r / min, and the ball milling time to 25min ;

[0046] Step 2: Control the temperature of the ball mill tank to 90°C through constant temperature circulating water, add the composite surface modifier in parts by mass, and mill for 25 minutes at a stirring speed of 500r / min; add magnesium stearate in parts by mass, and continue to W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com