Starch type dust suppressant and preparation method thereof

A technology of dust suppressant and starch, which is applied in the direction of chemical instruments and methods, and other chemical processes, can solve the problems that the dust suppression effect of dust suppressant needs to be improved, and achieve the effect of significant dust suppression effect, high viscosity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

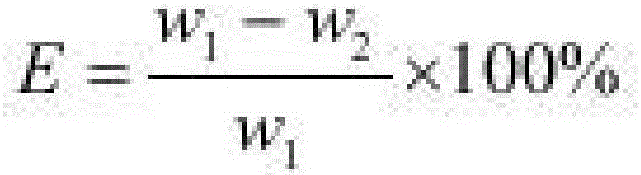

Method used

Image

Examples

Embodiment 1

[0031] Neutralize 18mL of acrylic acid with 30% NaOH solution to a neutralization degree of 70%, and set aside. Another 7.00 g of polyvinyl alcohol with an alcoholysis degree of 70% was placed in a 500 mL beaker, 150 mL of deionized water was added, and heated to 85° C. to completely dissolve it. After cooling down to room temperature, add the above-mentioned acrylic acid with a neutralization degree of 70%, and then sequentially add 2.00 g of cornstarch and 0.35% (accounting for the total mass percentage) of potassium persulfate, stir and mix well, and stir in a water bath at 65°C for 80 minutes. Cool to room temperature to obtain a modified starch solution.

[0032] Boil tap water for 20 minutes to obtain sterile water. Take 100mL of sterile water and place it in a 250mL conical flask that has been sterilized at high temperature, then add 5.00g of glucose, 0.23g of sodium glutamate, and 0.20g of chlorella powder, and use gauze seal. Cultivate at room temperature for 7 days...

Embodiment 2

[0043] Neutralize 18mL of acrylic acid with 30% KOH solution to a neutralization degree of 75%, and set aside. Another 7.00 g of polyvinyl alcohol with an alcoholysis degree of 98% was placed in a 500 mL beaker, 150 mL of deionized water was added, and heated to 85° C. to completely dissolve it. After cooling down to room temperature, add the above-mentioned acrylic acid with a neutralization degree of 75%, then sequentially add 2.00 g of tapioca starch and 0.30% (accounting for the total mass percentage) of ammonium persulfate, stir and mix, and stir in a water bath at 70°C for 60 min. Cool to room temperature to obtain a modified starch solution.

[0044] Boil tap water for 20 minutes to obtain sterile water. Take 100 mL of sterile water and place it in a 250 mL conical flask that has been sterilized at high temperature, then add 5.00 g of sucrose, 2.00 g of sodium glutamate, and 0.20 g of chlorella powder. seal. Cultivate at room temperature for 5 days. During the cultiva...

Embodiment 3

[0046]9 mL of acrylic acid was neutralized with a 30% NaOH solution to a neutralization degree of 85%, and set aside. Another 7.00 g of polyvinyl alcohol with an alcoholysis degree of 85% was placed in a 500 mL beaker, 150 mL of deionized water was added, and heated to 85° C. to completely dissolve it. After cooling down to room temperature, add the above-mentioned acrylic acid with a neutralization degree of 85%, then sequentially add 2.00 g of wheat starch and 0.35% (accounting for the total mass percentage) of potassium persulfate, stir and mix, and stir in a water bath at 60°C for 100 min. Cool to room temperature to obtain a modified starch solution.

[0047] Boil tap water for 20 minutes to obtain sterile water. Take 100mL of sterile water and place it in a 250mL conical flask that has been sterilized at high temperature, then add 5.00g of maltose, 0.23g of sodium glutamate, and 0.20g of chlorella powder. seal. Cultivate at room temperature for 10 days. During the cult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com