Method for retarding corrosion of rectification system of vinyl acetate device

A rectification system and vinyl acetate technology are applied in the field of slowing down the corrosion of the rectification system of a vinyl acetate unit, which can solve the problems of easily causing corrosion, increasing unplanned shutdowns, and increasing the maintenance cost of enterprise equipment, so as to reduce inspection and maintenance costs, solve or Corrosion Problems, Corrosion Mitigation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] This embodiment provides a method for slowing down the corrosion of the rectification system of a vinyl acetate unit, comprising the following steps:

[0067] Detect the content of corrosive substances in the rectification system;

[0068] Compare the content of detected corrosive substances with the fortification value of corrosive substances established according to the service material of the rectification system;

[0069] When the detected content of corrosive substances is higher than the fortification value of corrosive substances, part of the corrosive substances will be discharged from the discharge port set at the end of the rectification system;

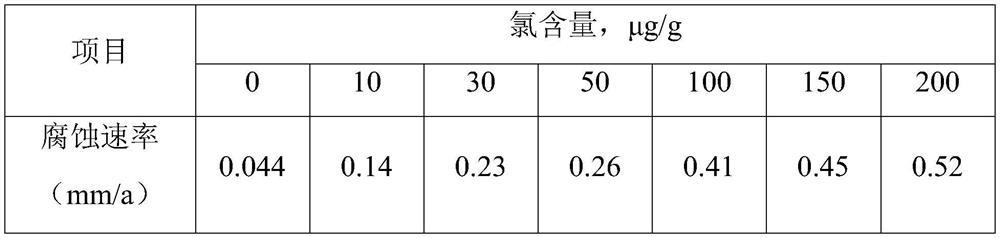

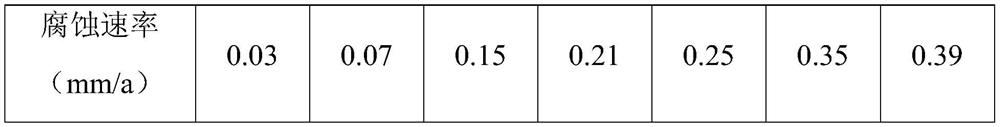

[0070] Among them, the corrosive substance is the chloride ion in the acetic acid material.

[0071] Set the fortification value for corrosive substances to 30 μg / g for chloride ions.

[0072] In the above process, detecting the content of corrosive substances in the rectification system includes: setting a samplin...

Embodiment 2

[0076] The difference between this embodiment and Embodiment 1 is that the fortification value of corrosive substances is set to 50 μg / g of chloride ions.

Embodiment 3

[0078] The difference between this embodiment and Embodiment 1 is that the fortification value of corrosive substances is set to 10 μg / g of chloride ions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com