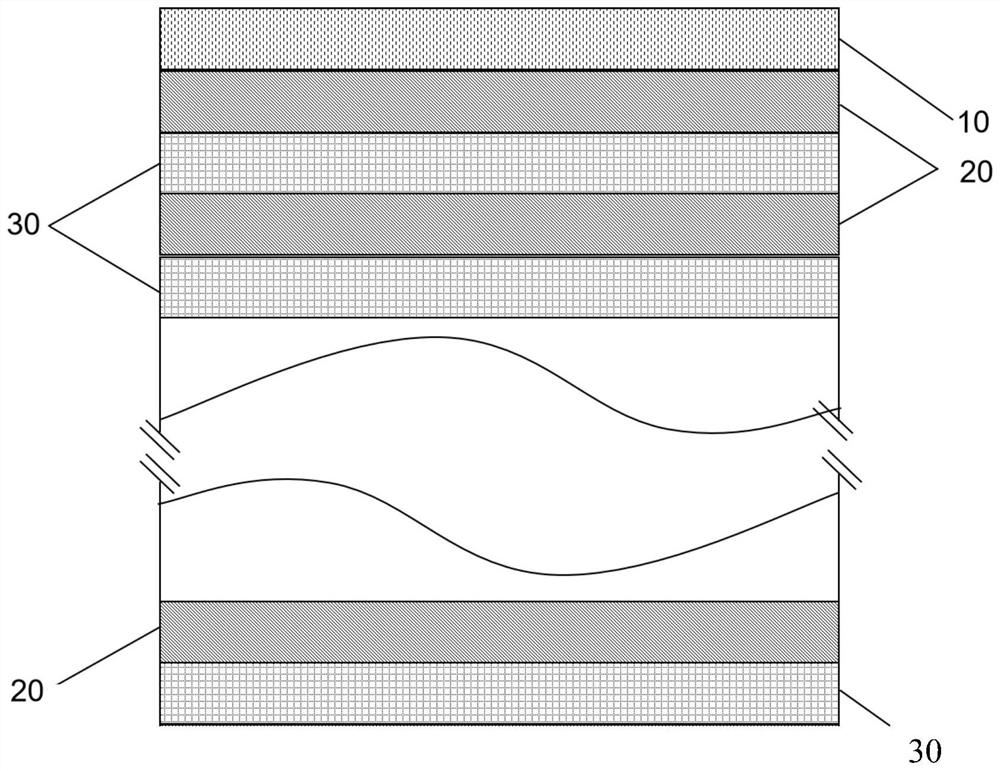

Light guide plate with infrared ray transmitting and visible light reflecting functions and backlight module

A technology of infrared rays and light guide plates, which is applied in the field of LCD backlight, can solve the problems that the backlight module cannot pass through infrared rays, etc., and achieve the effects of strong anti-internal stress performance, improved screen brightness, and improved light utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

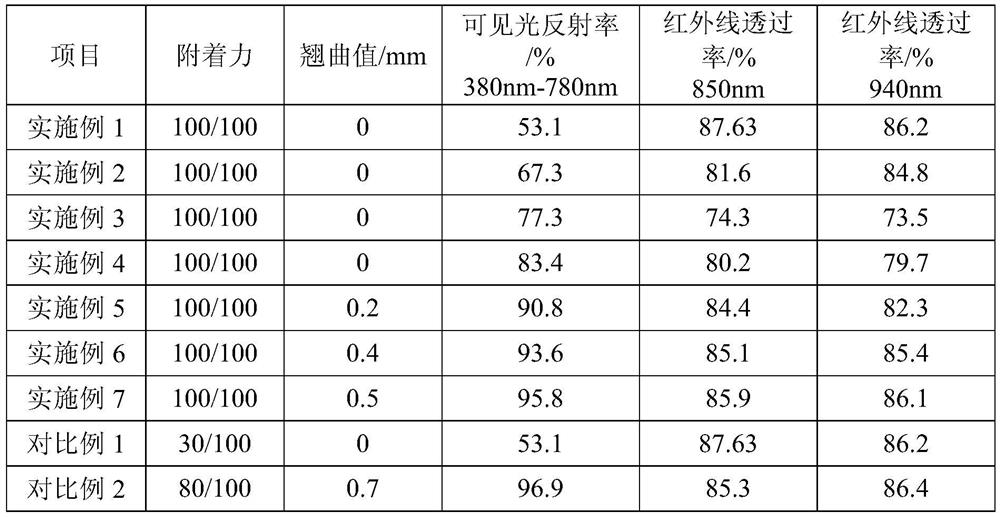

Embodiment 1

[0046] Provided is a light guide plate with a function of transmitting infrared rays and reflecting visible light. The substrate is made of polycarbonate (PC) and has a thickness of 0.36 mm. The preparation method includes the following steps:

[0047] (1) Nitrogen purges the surface of the substrate for 3 minutes to remove impurities of larger particles;

[0048](2) The vacuum degree of the coating chamber is 0.1 mbar, the flow rate of argon gas is 20 sccm, the negative bias power supply voltage is 700 V, and the surface of the above-mentioned substrate is cleaned by argon plasma bombardment for 10 minutes to remove the surface oxide and improve the surface energy of the substrate, which can improve the quality of the coating and the substrate. adhesion between sheets;

[0049] (3) Utilize high vacuum intermediate frequency magnetron sputtering to deposit Niobium pentoxide coating layer A on the above-mentioned substrate, the flow rate of argon gas is 120sccm, the flow rate o...

Embodiment 2

[0053] Provided is a light guide plate with a function of transmitting infrared rays and reflecting visible light. The substrate is made of polycarbonate (PC) and has a thickness of 0.36 mm. The preparation method includes the following steps:

[0054] (1) Nitrogen purges the surface of the substrate for 3 minutes to remove impurities of larger particles;

[0055] (2) The vacuum degree of the coating chamber is 0.1 mbar, the flow rate of argon gas is 20 sccm, the negative bias power supply voltage is 700 V, and the surface of the above-mentioned substrate is cleaned by argon plasma bombardment for 10 minutes to remove the surface oxide and improve the surface energy of the substrate, which can improve the quality of the coating and the substrate. adhesion between sheets;

[0056] (3) Utilize high vacuum intermediate frequency magnetron sputtering to deposit Niobium pentoxide coating layer A on the above-mentioned substrate, the flow rate of argon gas is 120sccm, the flow rate ...

Embodiment 3

[0060] Provided is a light guide plate with a function of transmitting infrared rays and reflecting visible light. The substrate is made of polycarbonate (PC) and has a thickness of 0.36 mm. The preparation method includes the following steps:

[0061] (1) Nitrogen purges the surface of the substrate for 3 minutes to remove impurities of larger particles;

[0062] (2) The vacuum degree of the coating chamber is 0.1 mbar, the flow rate of argon gas is 20 sccm, the negative bias power supply voltage is 700 V, and the surface of the above-mentioned substrate is cleaned by argon plasma bombardment for 10 minutes to remove the surface oxide and improve the surface energy of the substrate, which can improve the quality of the coating and the substrate. adhesion between sheets;

[0063] (3) Utilize high vacuum intermediate frequency magnetron sputtering to deposit Niobium pentoxide coating layer A on the above-mentioned substrate, the flow rate of argon gas is 120sccm, the flow rate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com