Iron-based magnetic powder with double coating layers as well as preparation method and application of iron-based magnetic powder

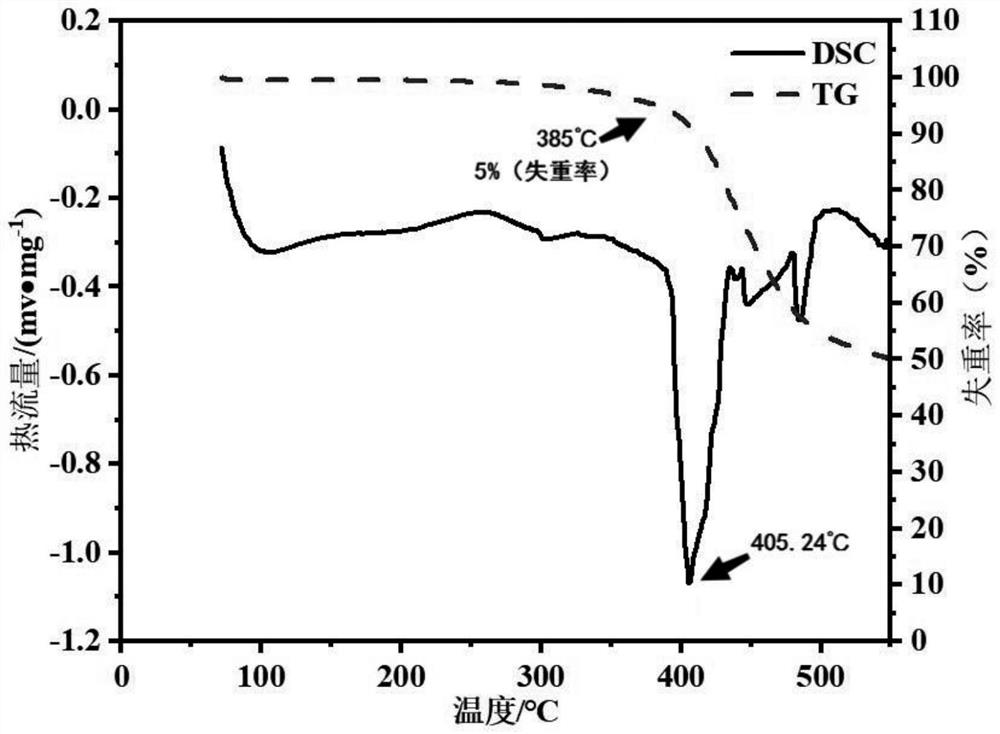

A double-cladding and cladding technology, applied in the field of metal soft magnetic powder cores, can solve the problems of overall temperature rise and performance degradation of magnetic powder cores, and achieve the effects of energy saving, environmental protection, mass production, improved solubility, and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The present embodiment provides a method for preparing a magnetic powder core, comprising the following steps:

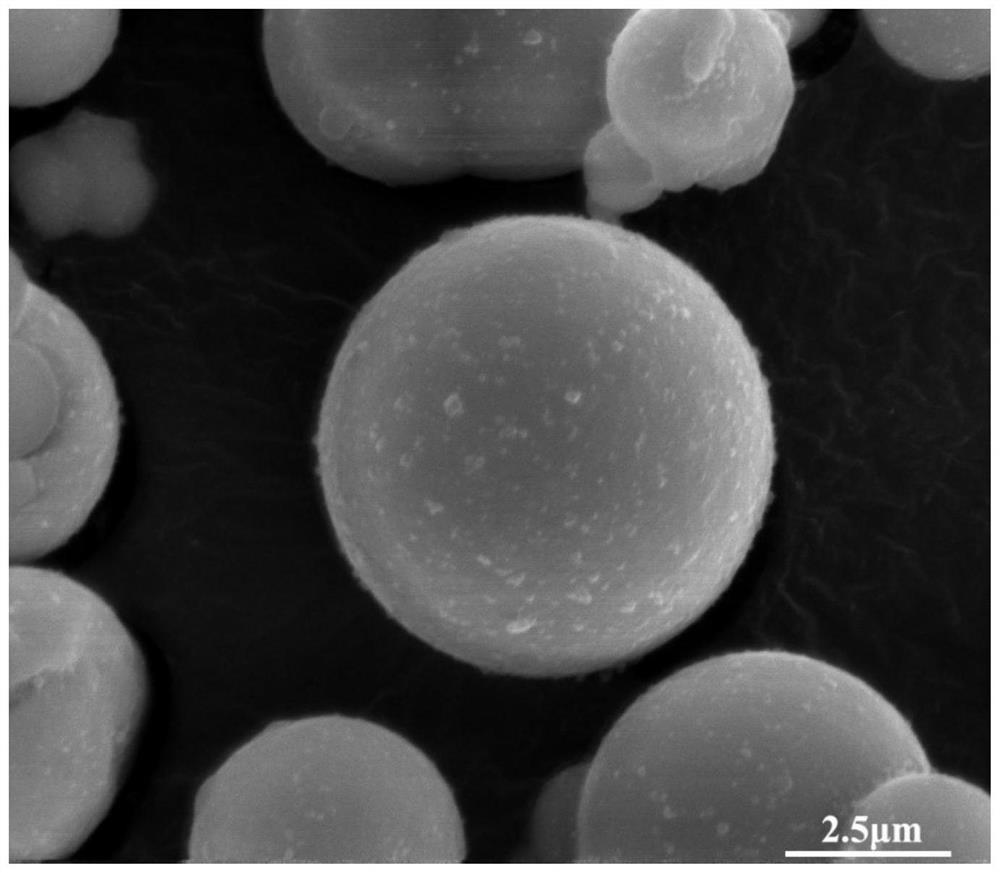

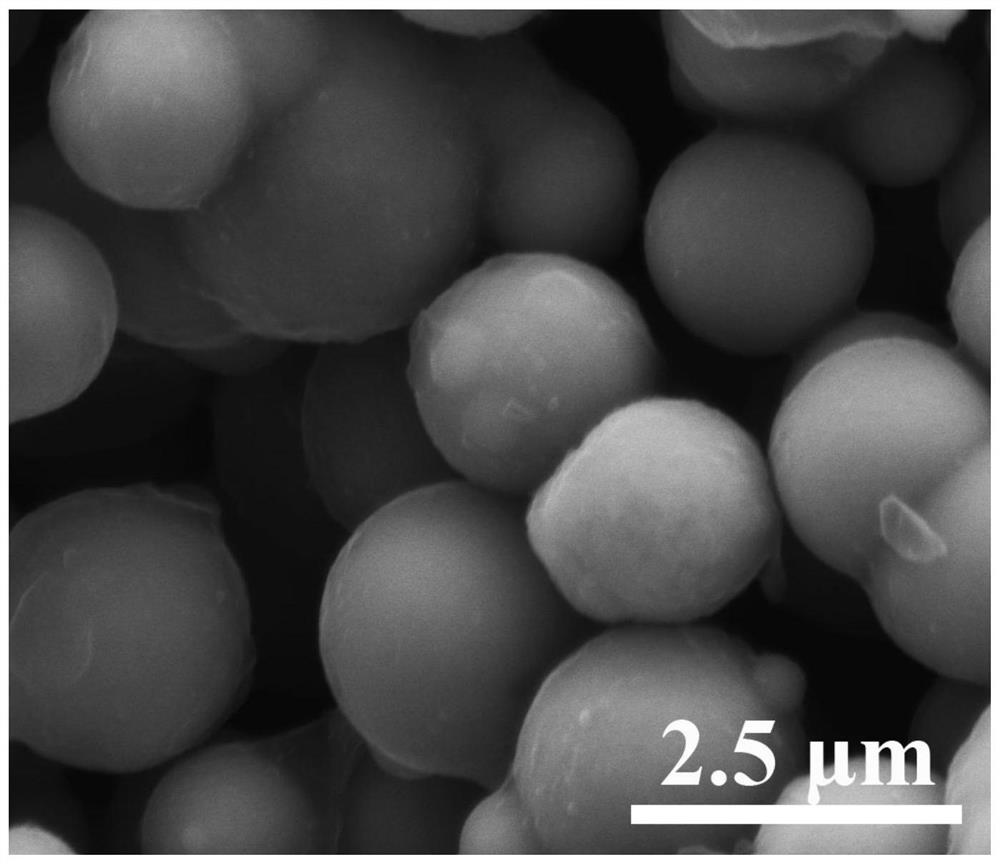

[0065] 1) Phosphating treatment: Weigh phosphoric acid, acetone and reduced carbonyl iron powder in a mass ratio of 7:200:1000 and mix them, and heat to 40°C while mechanically stirring at a rotational speed of 200 r / min until the acetone is completely volatilized, then Set it to dry at 120 °C for 1 hour, and sieve it with a 200-mesh sieve to obtain iron-based magnetic powder with a phosphate coating layer;

[0066] 2) Preparation of bismaleimide resin solution: put bismaleimide resin and dimethylformamide in a container according to the ratio of 40:100 and mix, and then according to acetone and bismaleimide resin The mass ratio of 40:1 is to get acetone and add it to the container, and use mechanical stirring to mix completely to obtain a bismaleimide resin solution (that is, a coating agent);

[0067] 3) resin coating treatment; the bismaleimide resin in s...

Embodiment 2

[0070] The present embodiment provides a method for preparing a magnetic powder core, comprising the following steps:

[0071] 1) Phosphating treatment: Weigh phosphoric acid, acetone and reduced carbonyl iron powder in a mass ratio of 7:200:1000 and mix them, and heat to 40°C while mechanically stirring at a rotational speed of 200 r / min until the acetone is completely volatilized, then Set it to dry at 120 °C for 1 hour, and sieve it with a 200-mesh sieve to obtain iron-based magnetic powder with a phosphate coating layer;

[0072] 2) Preparation of bismaleimide resin solution: put bismaleimide resin and dimethylformamide in a container according to the ratio of 40:100 and mix, and then according to acetone and bismaleimide resin The mass ratio of 40:1 is to get acetone and add it to the container, and use mechanical stirring to mix completely to obtain a bismaleimide resin solution (that is, a coating agent);

[0073] 3) Resin coating treatment; step 2) the bismaleimide re...

Embodiment 3

[0076] The present embodiment provides a method for preparing a magnetic powder core, comprising the following steps:

[0077] 1) Phosphating treatment: Weigh phosphoric acid, acetone and reduced carbonyl iron powder in a mass ratio of 7:200:1000 and mix them, and heat to 40°C while mechanically stirring at a rotational speed of 200 r / min until the acetone is completely volatilized, then Set it to dry at 120 °C for 1 hour, and sieve it with a 200-mesh sieve to obtain iron-based magnetic powder with a phosphate coating layer;

[0078] 2) Preparation of bismaleimide resin solution: put bismaleimide resin and dimethylformamide in a container according to the ratio of 40:100 and mix, and then according to acetone and bismaleimide resin The mass ratio of 40:1 is to get acetone and add it to the container, and use mechanical stirring to mix completely to obtain a bismaleimide resin solution (that is, a coating agent);

[0079] 3) resin coating treatment; the bismaleimide resin in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com