Integrally-formed inductor and preparation method thereof

An inductance and integrated technology, applied in the direction of transformer/inductor coil/winding/connection, coil manufacturing, etc., can solve the problems of increasing cost, sacrificing the magnetic characteristics of integrated inductance, and reducing the density of inductance in one-piece molding, so as to ensure stable storage performance, avoiding the decline of magnetic properties, and improving the effect of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In one aspect of the present invention, a method for preparing an integrally formed inductor is provided, comprising the following steps:

[0035] After the coil is embedded in the soft magnetic composite material and pressed into shape, it is baked and cured; the temperature of baking and curing is at least divided into 3 temperature gradients below 80°C for staged baking and curing, and the holding time of each temperature gradient is ≥0.5 h.

[0036] In the low temperature stage of baking and curing (below 80°C), the monolithic inductors are baked and cured in stages by using multiple gradient heating modes, so that the adhesive in the monolithic inductors can be fully cross-linked and cured, so that the monolithic inductor can be integrated. Molded inductors provide higher strength and improved cracking.

[0037] In some embodiments, the temperature for baking and curing below 80° C. may be divided into at least three temperature gradients for baking and curing, an...

Embodiment 1

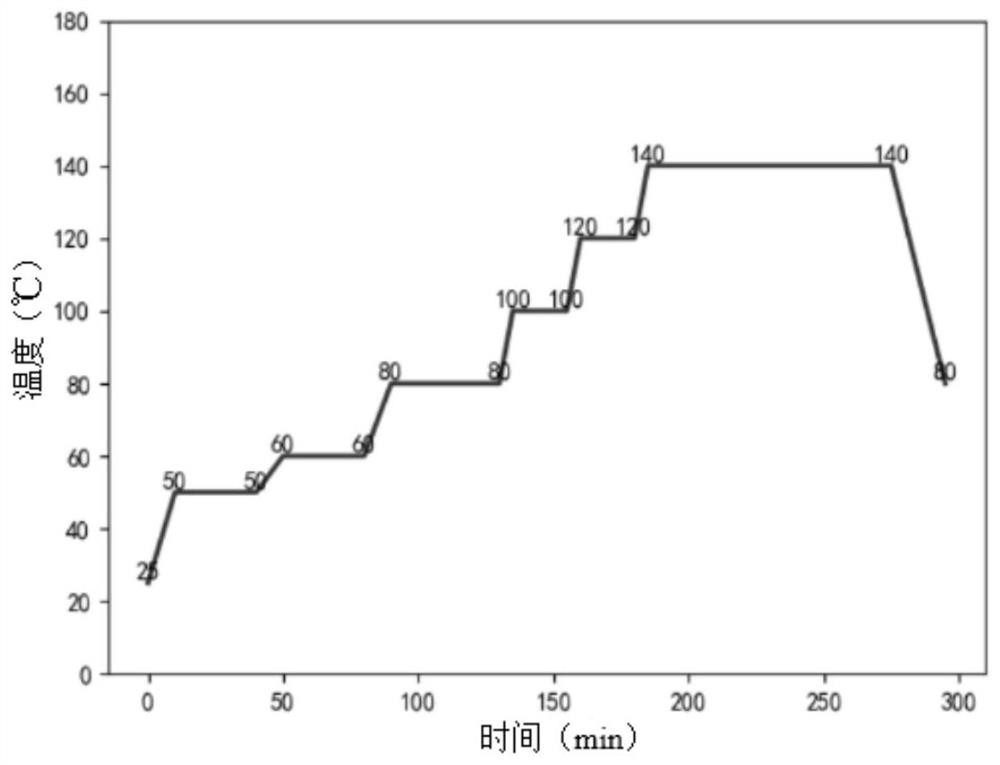

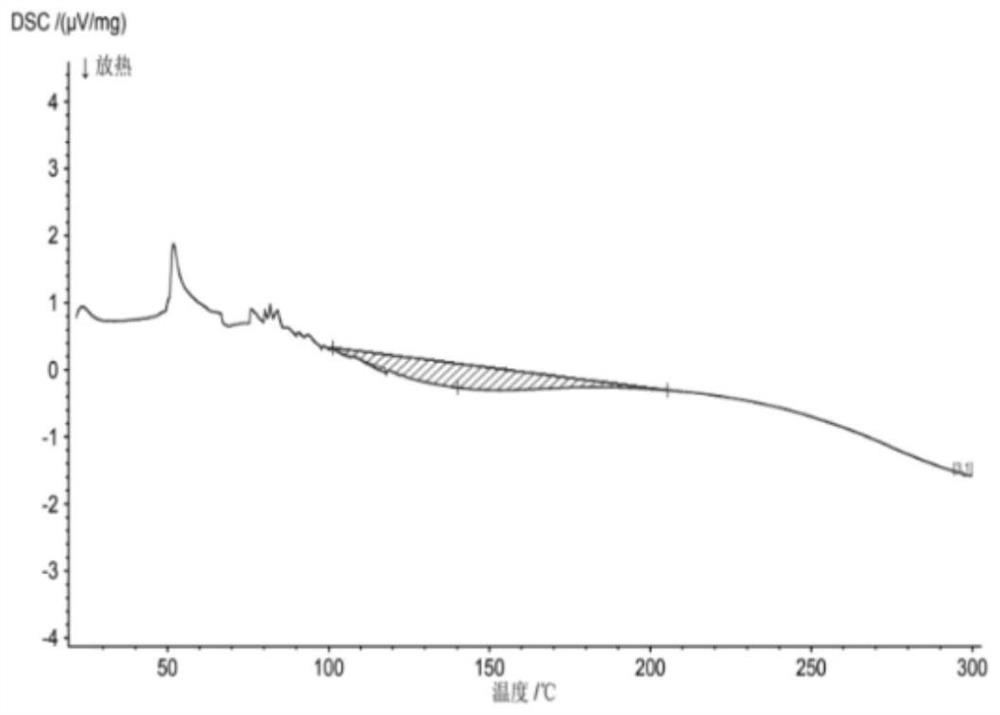

[0056] According to mass parts, 100 parts of FeSiCr-C soft magnetic alloy powder and 3.5 parts of resin binder J1 were taken respectively to prepare a soft magnetic composite material. Then at room temperature, powder metallurgy process is used to make soft magnetic composite material into one-piece inductor with model type 0630-100. Then according to figure 1 The curing curve shown is for baking and curing each type of 0630-100 one-piece integrated inductor. Depend on figure 1 It can be seen that the curing process in the low temperature curing stage (25 °C ~ 80 °C) is: 1) at 25 °C, at a heating rate of 2.5 °C / min to 50 °C, and keep it for 30 minutes; 2) at a temperature of 1 °C / min The temperature was raised to 60°C at a rate and kept for 30 minutes; 3) the temperature was raised to 80°C at a heating rate of 2°C / min, and the temperature was kept for 40 minutes. The DSC curing curve of cured resin adhesive J1 is as follows figure 2 shown. Depend on figure 2 It was fou...

Embodiment 2

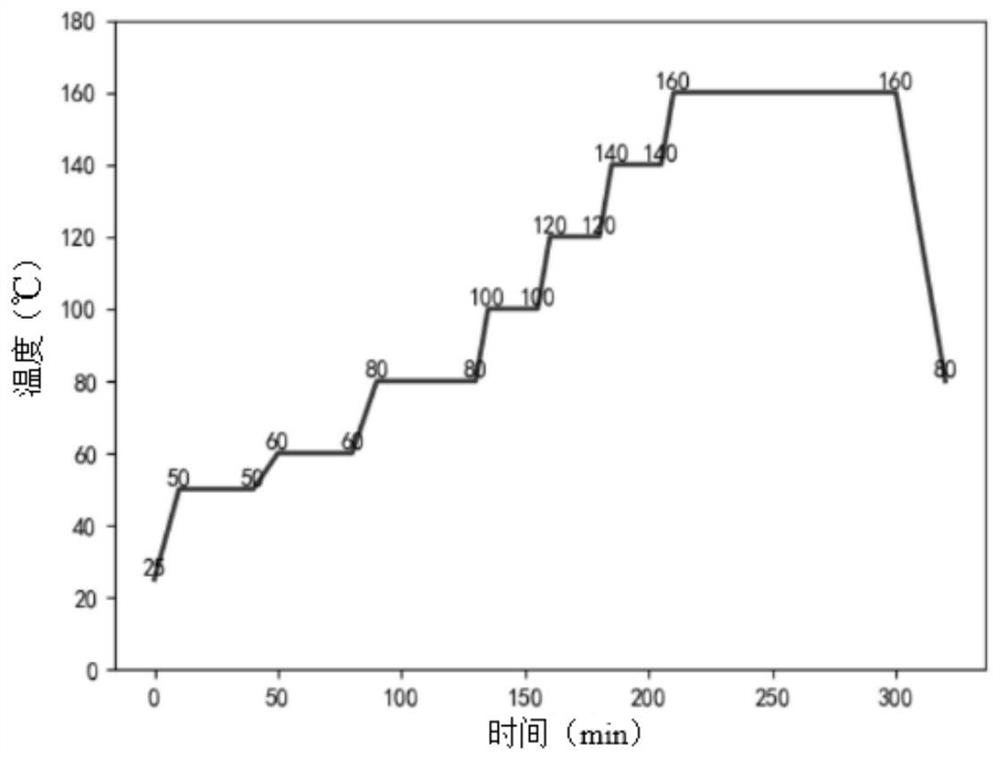

[0058] According to mass parts, 100 parts of RTE carbonyl iron powder and 3.5 parts of resin binder J2 were taken respectively to prepare a soft magnetic composite material. Then at room temperature, powder metallurgy process is used to make soft magnetic composite material into one-piece inductor with model type 0630-100. Then according to image 3 The curing curve shown is for baking and curing each type of 0630-100 one-piece integrated inductor. Depend on image 3 It can be seen that the curing process in the low temperature curing stage (25 °C ~ 80 °C) is: 1) at 25 °C, at a heating rate of 2.5 °C / min to 50 °C, and keep it for 30 minutes; 2) at a temperature of 1 °C / min The rate was heated to 60°C and kept for 30min;

[0059] 3) The temperature was raised to 80°C at a heating rate of 2°C / min, and the temperature was maintained for 40 minutes. The DSC curing curve of cured resin adhesive J2 is as follows Figure 4 shown. Depend on Figure 4 It was found that the initi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

| Curing peak temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com