Lithium iron phosphate positive plate comprehensive recycling equipment

A technology of lithium iron phosphate and positive electrode sheet, which is applied in the field of comprehensive recycling equipment for lithium iron phosphate positive electrode sheet, can solve the problems of low purity of lithium iron phosphate, use of battery positive electrode materials, and time-consuming and laborious treatment of waste liquid, etc., to achieve The effect of improving work efficiency, reducing recycling cost and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

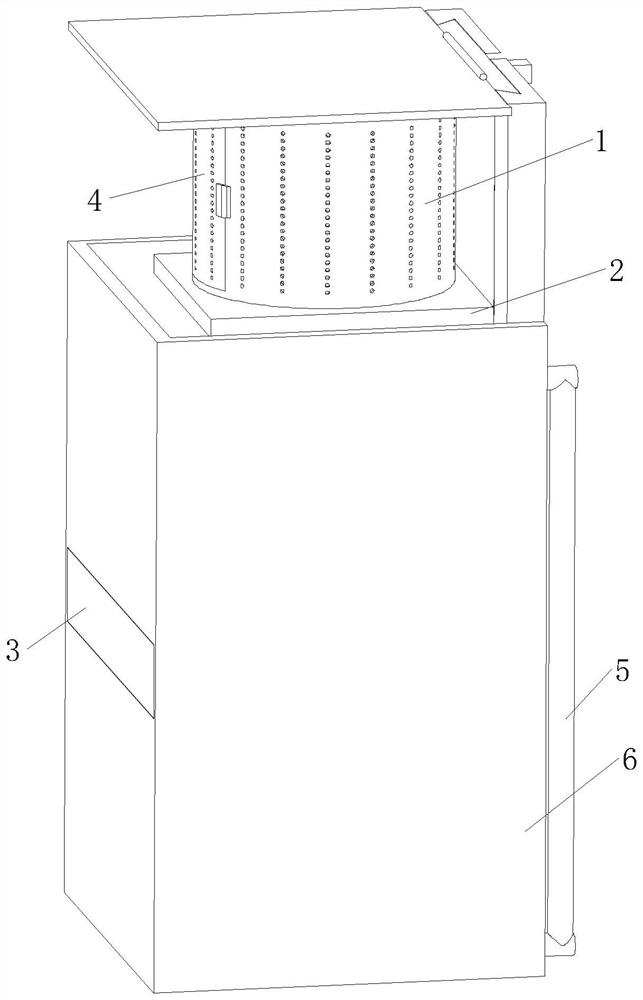

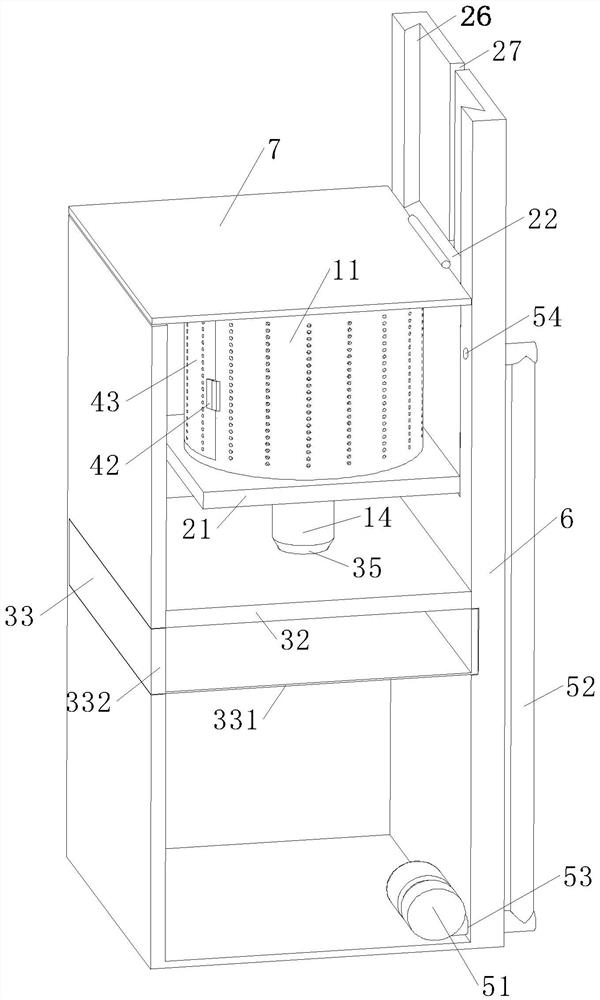

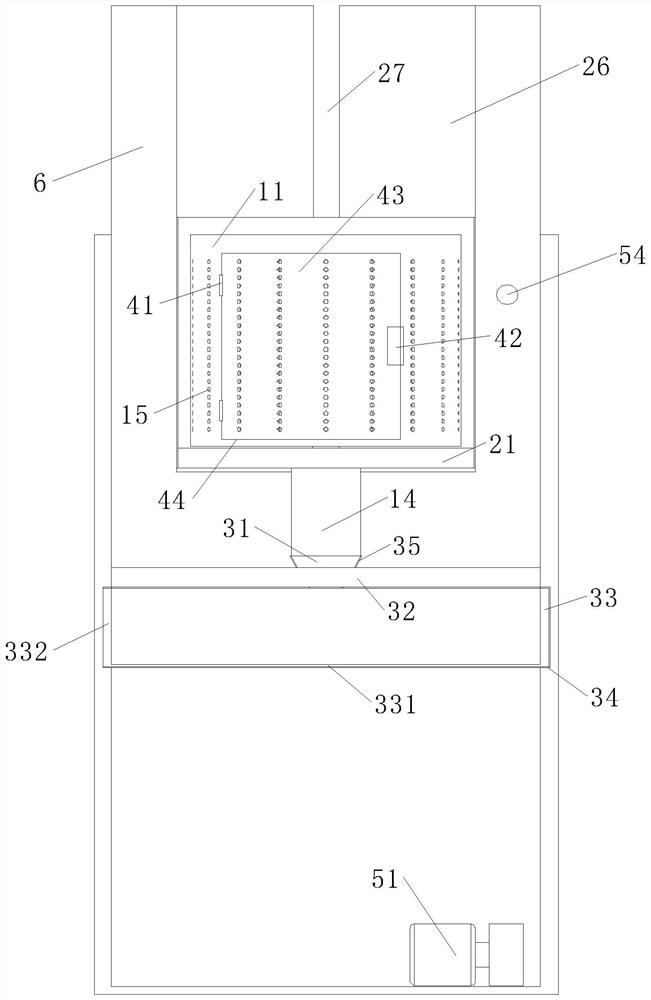

[0030] In order to make it easy to understand the technical means, creation features, achieved goals and effects of the present invention, the present invention will be further described below with reference to the specific embodiments.

[0031] This embodiment provides a comprehensive recycling equipment for lithium ferrous phosphate cathode sheets, which solves the problem that in the existing equipment, roasting and chemical methods are often used to recover lithium ferrous phosphate. Although the roasting method is simple, it consumes a large amount of energy. , the recovered product will produce impurities, resulting in the low purity and low quality of the recovered lithium ferrous phosphate, and can no longer be used as a positive electrode material for the battery, but is recycled by chemical methods, and the current collector, conductive agent, bonding agent of the positive electrode sheet is recovered. This method consumes a large amount of chemical agents and produce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com