Preparation method of polydimethylsiloxane composite sponge capable of continuously and efficiently filtering PM

A technology of polydimethylsiloxane and composite sponge, which is applied in the direction of separation methods, dispersed particle filtration, chemical instruments and methods, etc., can solve the problems of narrow application range, poor continuous performance and mechanical properties, and achieve simple preparation process , short cycle, low pressure drop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

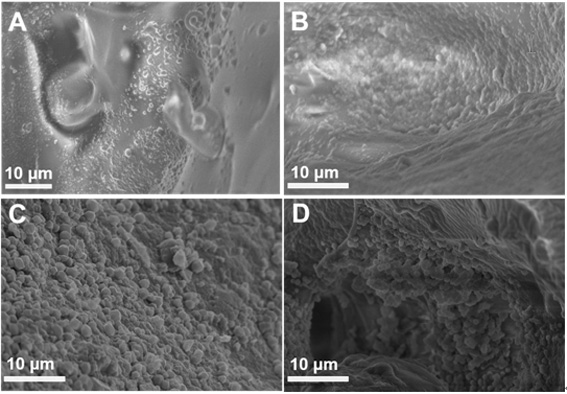

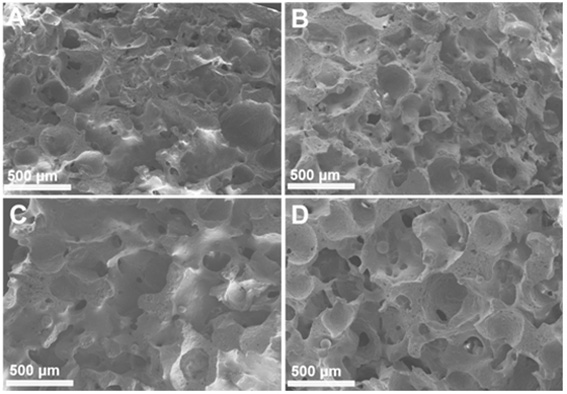

[0031] A kind of preparation method of the polydimethylsiloxane composite sponge of continuous high-efficiency filtering PM, its concrete steps are as follows:

[0032] (1) Preparation of PDMS sponge by sacrificial template method

[0033] Take an appropriate amount of citric acid monohydrate granules and thoroughly grind them into powder in a mortar, then fully stir the citric acid monohydrate powder and polydimethylsiloxane to make them evenly mixed, and then transfer them to the desired mold, and press repeatedly. After exhausting the air, it was placed in an oven at 150 °C to cure overnight, then placed in deionized water, and citric acid monohydrate was dissolved by ultrasound, and then dried in an oven at 60 °C to obtain a three-dimensional porous PDMS sponge; the citric acid monohydrate used and the The mass ratio of PDMS is 3-6:1;

[0034] (2) PDA@PDMS composite sponge prepared by self-polymerization of dopamine hydrochloride

[0035] Dopamine hydrochloride (DA) and ...

Embodiment 1

[0042] This embodiment prepares a polydimethylsiloxane (PDMS) composite sponge that continuously and efficiently filters PM under harsh environments such as high temperature and high humidity according to the following steps:

[0043] Step 1: Preparation of PDMS sponge by sacrificial template method

[0044] Take an appropriate amount of citric acid monohydrate granules and grind them thoroughly in a mortar to powder, then mix 3 parts by weight of citric acid monohydrate powder and 1 part by weight of polydimethylsiloxane fully to make it evenly mixed and then transfer to the desired In the mold, after repeated pressing to discharge air, it was placed in a 150°C oven to cure overnight, then placed in deionized water, and citric acid monohydrate was dissolved by ultrasound, and then dried in an oven at 60°C to obtain a three-dimensional porous PDMS sponge;

[0045] Step 2: Self-polymerization of dopamine hydrochloride to prepare PDA@PDMS composite sponge;

[0046] Dopamine hyd...

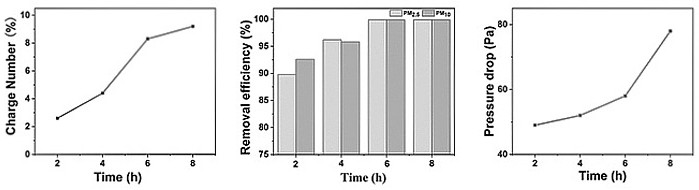

Embodiment 2

[0050] The soaking in step 3 of Example 1 was actually replaced by 4h, and other operations were as in Example 1 to obtain ZIF-8@PDA@PDMS composite sponge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com