Electrochemical catalytic oxidation device, system and method for treating wastewater

A technology for catalytic oxidation and wastewater treatment, applied in physical/chemical process catalysts, chemical instruments and methods, electrochemical water/sewage treatment, etc. problems, to achieve the effect of improving processing efficiency, low preparation cost, and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

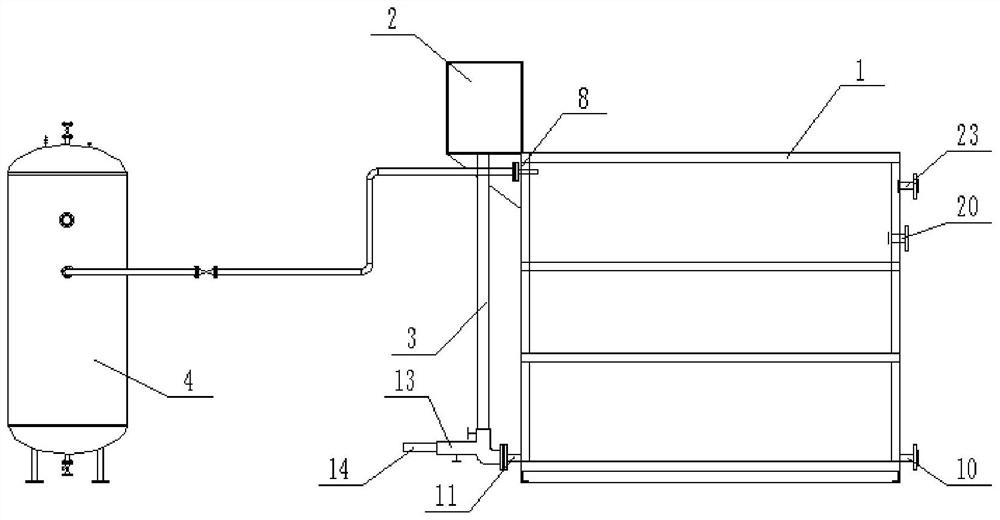

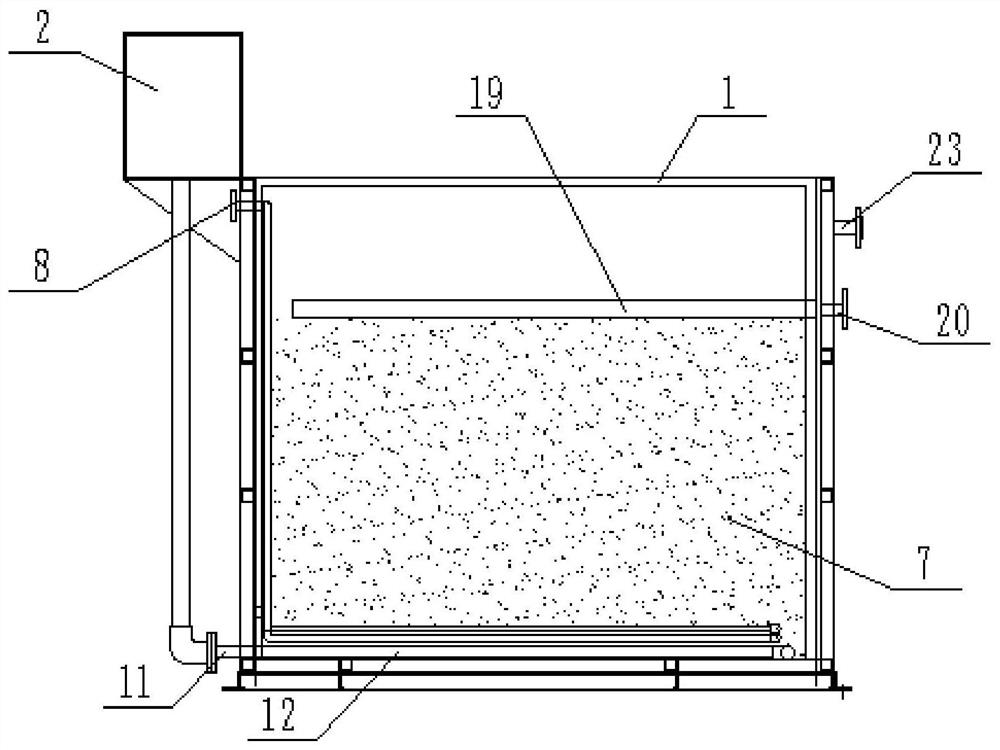

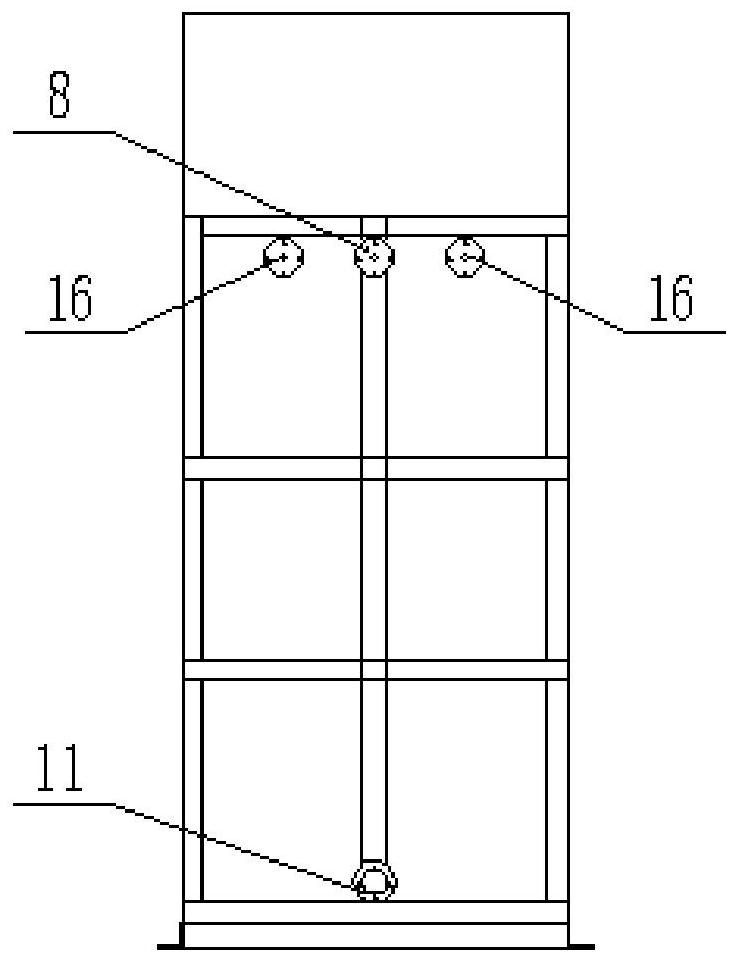

[0037] like Figures 1 to 8 As shown, the present invention discloses an electrochemical catalytic oxidation device for treating wastewater, which includes a housing 1 , a water distribution tank 2 , a water distribution pipe 3 , a gas storage tank 4 , a blower, an electrode anode 5 and an electrode cathode 6 .

[0038] The electrode anode 5 and the electrode cathode 6 are arranged on both sides of the housing 1 and connected to the power supply respectively. The electrode anode 5 adopts a graphite carbon plate, and the electrode cathode 6 adopts a stainless steel plate. The bottom of the casing 1 is provided with a water distribution area, an aeration area and a backwashing area, and the top of the casing 1 is provided with a water outlet area. The inside of the housing 1 between the water outlet area and the water distribution area is filled with a catalyst 7 .

[0039]The water distribution area includes a water inlet flange 11 and a water distribution pipe group 12 . Th...

Embodiment 2

[0046] like Figure 1-8 As shown, the present invention discloses an electrochemical catalytic oxidation device for treating waste water. In the present embodiment, the catalyst 7 includes the following components by weight fraction: 30 parts of activated carbon, 8 parts of binder, 12 parts of iron Oxides of copper, 18 parts of copper oxides, 4 parts of manganese oxides, 2 parts of zinc oxides, 3 parts of zirconium oxides, 4 parts of cerium oxides, and 4 parts of titanium oxides.

[0047] Other technical characteristics are consistent with the embodiment.

Embodiment 3

[0049] like Figure 1-8 As shown, the present invention discloses an electrochemical catalytic oxidation device for treating waste water. In this embodiment, the catalyst 7 includes the following components by weight fraction: 35 parts of activated carbon, 15 parts of binder, 18 parts of iron Oxides of copper, 22 parts of copper oxides, 7 parts of manganese oxides, 4 parts of zinc oxides, 5 parts of zirconium oxides, 5 parts of cerium oxides, and 7 parts of titanium oxides.

[0050] Other technical characteristics are consistent with the embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com