Sizing agent, preparation method thereof and paper coated with sizing agent

A sizing agent and catalyst technology, applied in papermaking, coating, paper coating and other directions, can solve the problems of non-degradability, environmental pollution, affecting the water resistance and tensile strength of paper, and achieve improved performance and good water resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

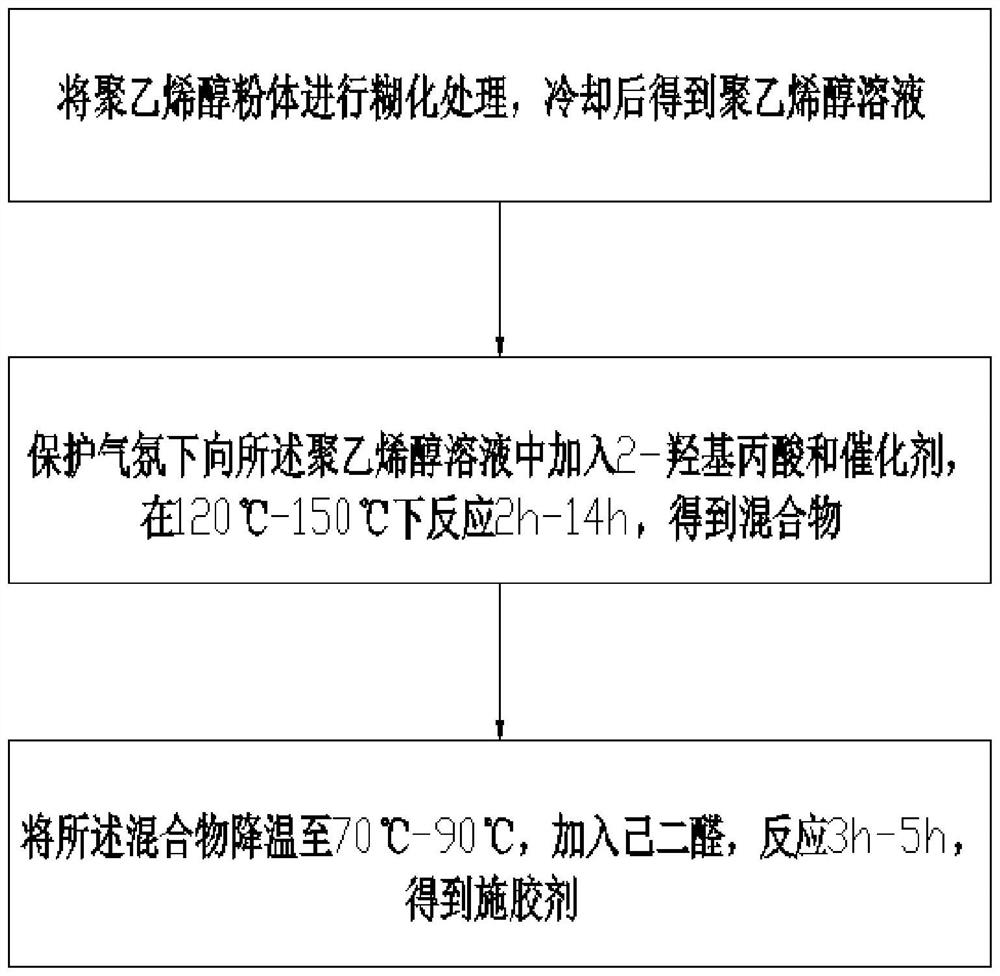

[0022] see figure 1 As shown, a preparation method of a sizing agent according to an embodiment of the present invention includes:

[0023] Step S1, gelatinizing the polyvinyl alcohol (PVA) powder, and cooling to obtain a polyvinyl alcohol solution;

[0024] Step S2, adding 2-hydroxypropionic acid and a catalyst to the polyvinyl alcohol solution under a protective atmosphere, and reacting at 120°C-150°C for 2h-14h to obtain a mixture;

[0025] Step S3, cooling the mixture to 70°C-90°C, adding adipaldehyde, and reacting for 3h-5h to obtain a sizing agent.

[0026] In this example, the PVA powder is gelatinized to obtain a usable polyvinyl alcohol solution, and it is reacted with 2-hydroxypropionic acid (also called lactic acid), so that the lactic acid is grafted onto the PVA chain to improve film formation. The final sizing agent is degradable, has no harm to the environment, and has good water resistance, oxygen barrier properties and tensile strength.

[0027] In some emb...

Embodiment 1

[0035] Disperse 10g of PVA in 90g of water, heat it to 90°C, stir for 30 minutes, after the PVA is completely dissolved, cool it for later use, heat the gelatinized PVA to 60°C, introduce nitrogen, empty the air, and add 1g of 2 -Hydroxypropionic acid, then add 0.03g of catalyst tin dioxide; heat the above mixture to 120°C, react for 2h, after the reaction is over, cool down to 70°C, add 5g of adipaldehyde, react for 3 hours, and discharge after cooling, Get the sizing agent.

Embodiment 2

[0037] Disperse 12g of PVA in 88g of water, heat it to 90°C, stir for 30 minutes, wait until the PVA is completely dissolved, cool it for later use, heat the gelatinized PVA to 60°C, introduce nitrogen, empty the air, and add 2g 2 -Hydroxypropionic acid, then 0.07g catalyst tin dioxide was added; the above mixture was heated to 140°C and reacted for 6h. After the reaction was over, the temperature was lowered to 70°C, 10g of adipaldehyde was added, and the reaction was performed for 4 hours. After cooling, the material was discharged. Get the sizing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com