Silica hydrogel contact lens and formula and preparation method thereof

A technology for contact lenses and silicone hydrogels, which is applied to instruments, optical components, optics, etc., can solve the problems of insufficient hardness, low pass rate, lens damage, etc., and achieve the effects of saving production costs, low cost, and high pass rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

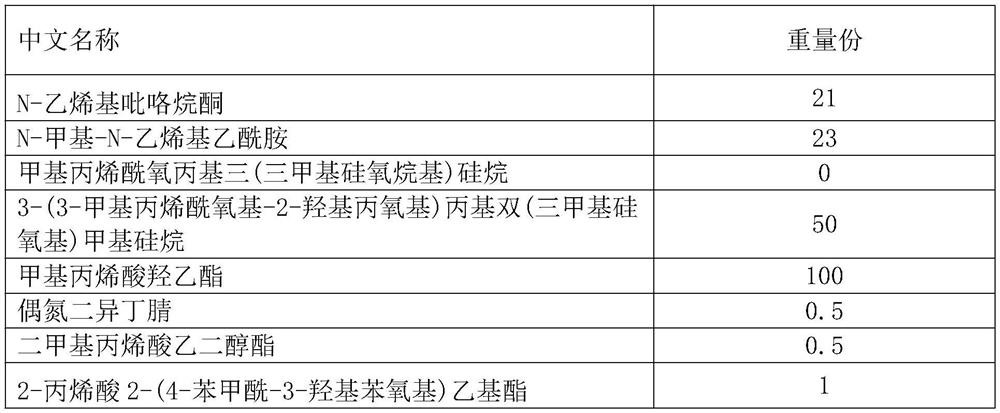

[0038] The formula of this example is shown in Table 1:

[0039] Table 1

[0040]

[0041] The preparation method of the silicone hydrogel contact lens of the present embodiment comprises the following steps:

[0042] S1. Stir at a low speed at 25°C to dissolve all the above materials and mix them evenly. The stirring time is more than 0.5 hours. The obtained mixed solution was filtered through a pressure filter with a pore size of 0.2 microns to obtain a polymerization solution. The mold is injected into the mold by an automatic liquid injection machine, and the mold is closed, and then the closed mold is transferred to a nitrogen oven for curing. The mold is made of polybutylene terephthalate (PBT) material or polypropylene (PP) material.

[0043] The curing procedure is as follows: the room temperature is raised to 65°C for 30 minutes, then the temperature is increased to 95°C at a constant rate for 1 hour, the temperature is kept for 1 hour, the heat is stopped, and t...

Embodiment 2

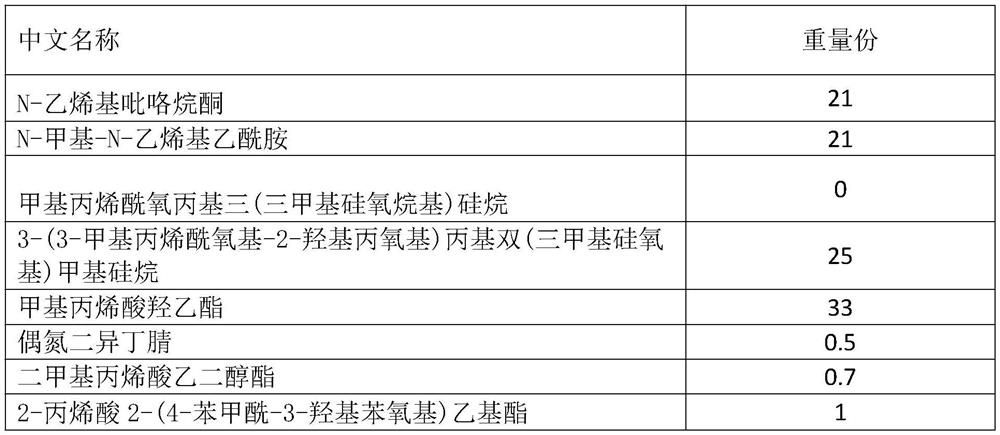

[0049] The formula of the present embodiment is shown in Table 2:

[0050] Table 2

[0051]

[0052] The preparation method of the silicone hydrogel contact lens of the present embodiment comprises the following steps:

[0053] S1. Stir at a low speed at 25°C to dissolve all the above materials and mix them evenly. The stirring time is more than 0.5 hours. The obtained mixed solution was filtered through a pressure filter with a pore size of 0.2 microns to obtain a polymerization solution. The mold is injected into the mold by an automatic liquid injection machine, and the mold is closed, and then the closed mold is transferred to a nitrogen oven for curing. The mold is made of polybutylene terephthalate (PBT) material or polypropylene (PP) material.

[0054] The curing procedure is as follows: the room temperature is raised to 65°C for 30 minutes, then the temperature is increased to 95°C at a constant rate for 1 hour, the temperature is kept for 1 hour, the heat is stop...

Embodiment 3

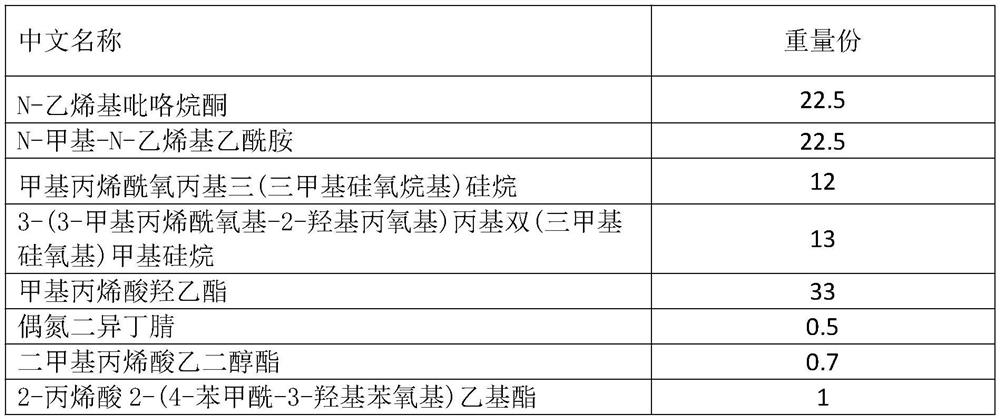

[0058] The formula of the present embodiment is shown in Table 3:

[0059] table 3

[0060]

[0061] The preparation method of the silicone hydrogel contact lens of the present embodiment comprises the following steps:

[0062] S1. Stir at a low speed at 25°C to dissolve all the above materials, mix evenly, and stir for more than 0.5 hours. The obtained mixed solution was filtered through a pressure filter with a pore size of 0.2 microns to obtain a polymerization solution. The mold is injected into the mold by an automatic liquid injection machine, and the mold is closed, and then the closed mold is transferred to a nitrogen oven for curing. The mold is made of polybutylene terephthalate (PBT) material or polypropylene (PP) material.

[0063]The curing procedure is as follows: the room temperature is raised to 65°C for 30 minutes, then the temperature is increased to 95°C at a constant rate for 1 hour, the temperature is kept for 1 hour, the heat is stopped, and the plas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com