Weld joint protection cooling device and method for solving problem that titanium alloy cast ingot is prone to cracking after welding

A cooling device, titanium alloy technology, applied in furnaces, furnace types, heat treatment equipment, etc., can solve problems such as easy cracking of titanium alloy ingots, slow cooling rate, and easy cracking of welds, so as to avoid coarsening of grains, The effect of reducing welding heat input and improving weld strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The above experiments, including the results finally obtained by the experiments, are only embodiments adopted to facilitate the understanding of the technical solutions of the invention, and are not intended to limit the present invention.

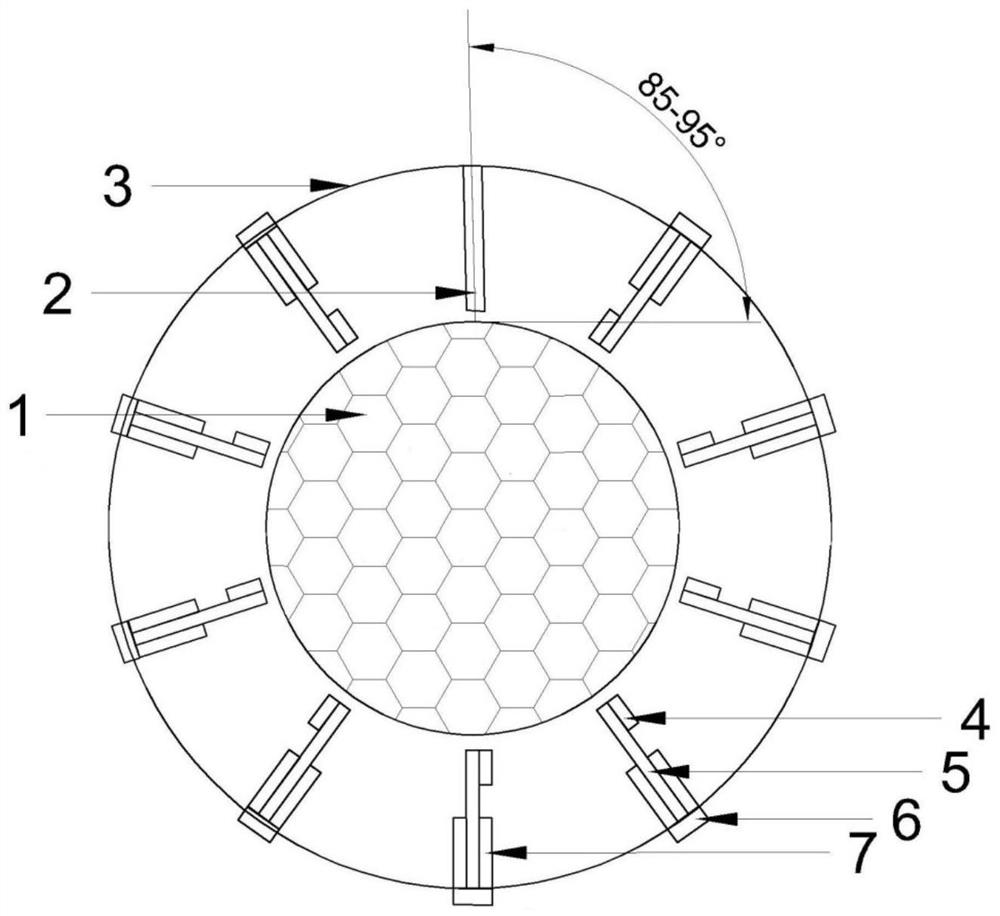

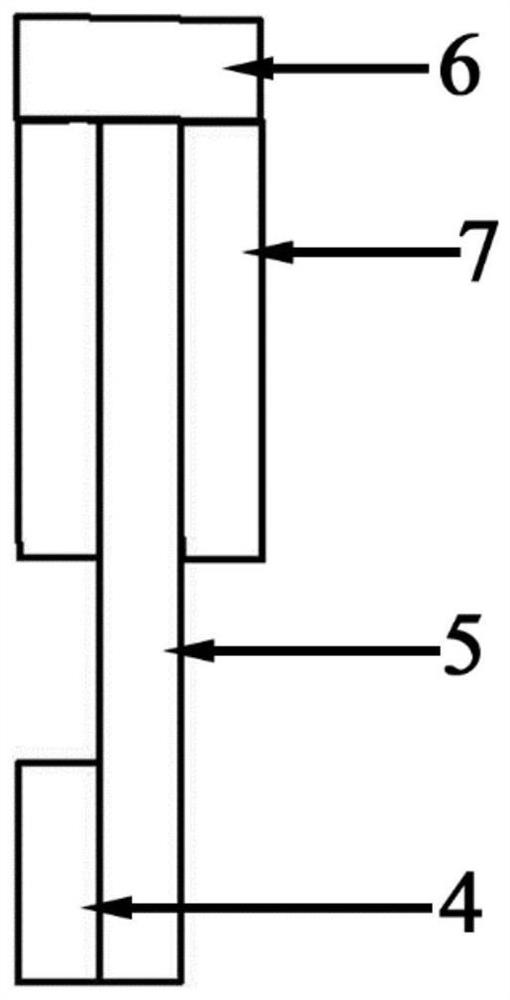

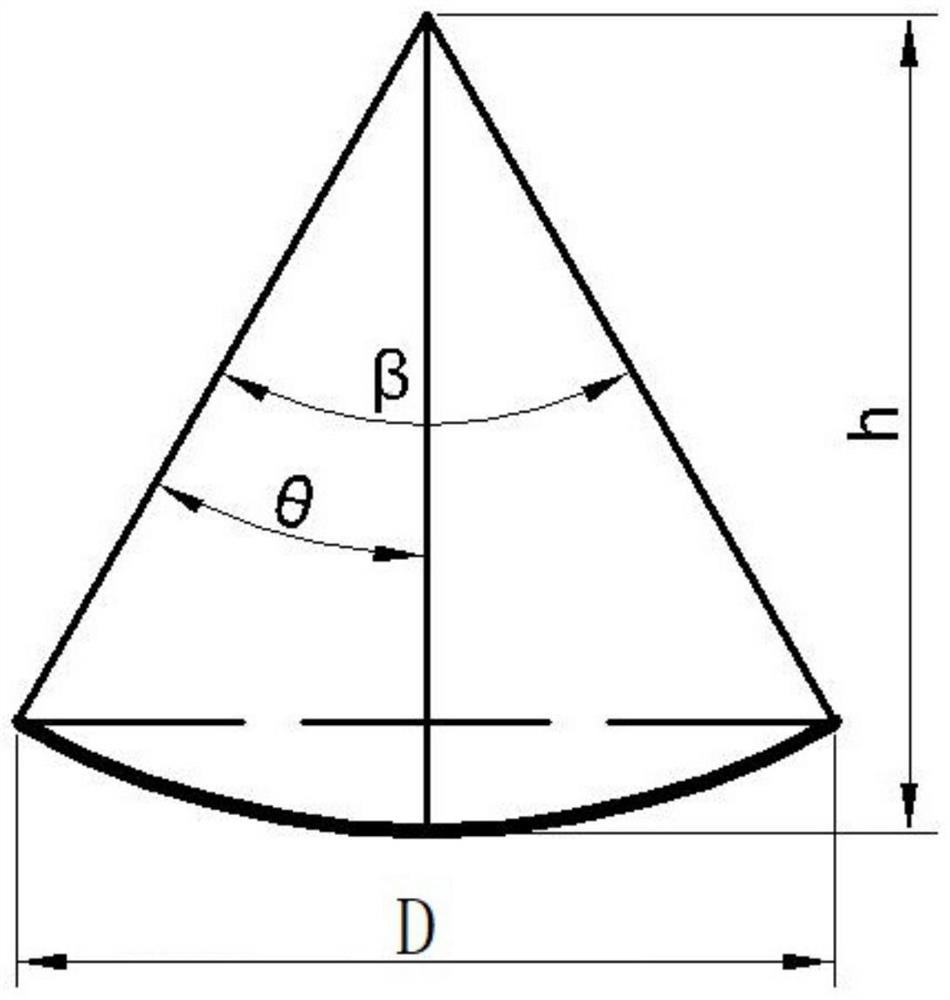

[0045]Select 2 TC4 titanium alloy ingots with a diameter of 560mm, adjust the angle between the swaying plasma welding torch and the welding seam to 90°, the "pulse" rotation frequency of the TC4 titanium alloy ingot is 5° / min, and the pause time is 2s. The swinging angle of the swaying plasma welding torch is θ=4°, the welding power is turned on, and arc welding starts; meanwhile, the welding seam protection and cooling device is arranged around the cylindrical vacuum chamber to protect and cool the welding seam immediately, and set the average cooling of the welding seam. The speed is controlled at 35°C / min, and the weld temperature at the end of welding is 130°C; after being released from the furnace, the ingot weld shows a good ...

Embodiment 2

[0047] Select 2 Ti1023 titanium alloy ingots with a diameter of 440mm, adjust the angle between the swaying plasma welding torch and the welding seam to 92°, the "pulse" rotation frequency of the Ti1023 titanium alloy ingot is 2° / min, and the pause time is 4s. The swing angle of the swaying plasma welding torch is θ=2°, the welding power is turned on, and the arc welding starts; meanwhile, the welding seam protection cooling device is arranged around the cylindrical vacuum chamber to protect and cool the welding seam immediately, and set the average cooling of the welding seam. The speed is controlled at 50°C / min, and the weld temperature at the end of welding is 70°C; after being released from the furnace, the ingot weld shows a good titanium alloy luster, and the weld is uniform and full without cracks.

Embodiment 3

[0049] Select 2 TA15 titanium alloy ingots with a diameter of 560mm, adjust the angle between the swaying plasma welding torch and the weld to 90°, the "pulse" rotation frequency of the TA15 titanium alloy ingot is 3° / min, and the pause time is 2s. The swing angle of the swaying plasma welding torch is θ=5°, the welding power is turned on, and arc welding starts; meanwhile, the welding seam protection cooling device is arranged around the cylindrical vacuum chamber to protect and cool the welding seam immediately, and set the average cooling of the welding seam. The speed is controlled at 40°C / min, and the weld temperature at the end of welding is 120°C; after being released from the furnace, the ingot weld shows a good titanium alloy luster, and the weld is uniform and full without cracks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com