Compressor silencer and manufacturing process thereof

A manufacturing process and technology for mufflers, which are used in machines/engines, mechanical equipment, liquid variable capacity machinery, etc., can solve the problems of reduced muffling frequency and muffling range, inability to eliminate, and weak low-frequency muffling capability. Increased density and wall thickness uniformity, good thermal and sound insulation, and reduced molding shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

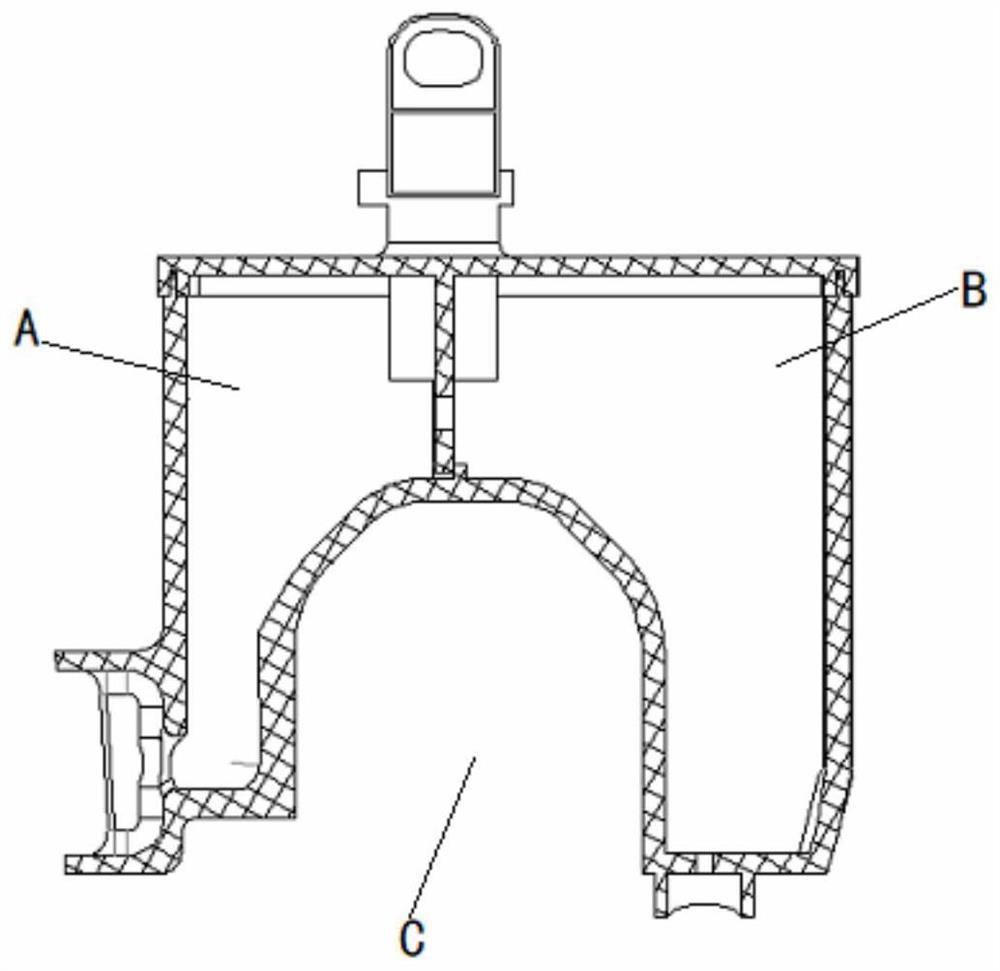

[0060] like Figure 3 to Figure 5 As shown, in the compressor muffler of the above structure, the separation ratio of the second muffler cavity 7 and the first muffler cavity 6 is 0.3, the length of the first muffler cavity 6 is 63mm, the width is 25mm, and the height is 45mm. The length of the acoustic cavity 7 is 63mm, the width is 25mm, the height is 13.5mm, the length of the wavelength tube is 20mm, and the opening area S of the insertion tube I22 is 12.56mm 2 , the volume V of the resonant cavity 5 is 1920mm 3 . The length t of the insertion tube I22 is 6mm.

Embodiment 2

[0062] The difference from Embodiment 1 is that the separation ratio between the second muffler cavity 7 and the first muffler cavity 6 is 0.4, the height of the first muffler cavity 6 is 42 mm, and the height of the second muffler cavity 7 is 16.8 mm.

Embodiment 3

[0064] The difference from Embodiment 1 is that the separation ratio between the second muffler cavity 7 and the first muffler cavity 6 is 0.5, the height of the first muffler cavity 6 is 40 mm, and the height of the second muffler cavity 7 is 20 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com