Ultrasonic flaw detection method

A detection method, ultrasonic flaw detection technology, applied in the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, measuring devices, and use sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., which can solve the problems of poor near-surface resolution, high defect missed detection rate, High labor intensity and other problems, to meet the requirements of high signal-to-noise ratio, improve detection efficiency, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

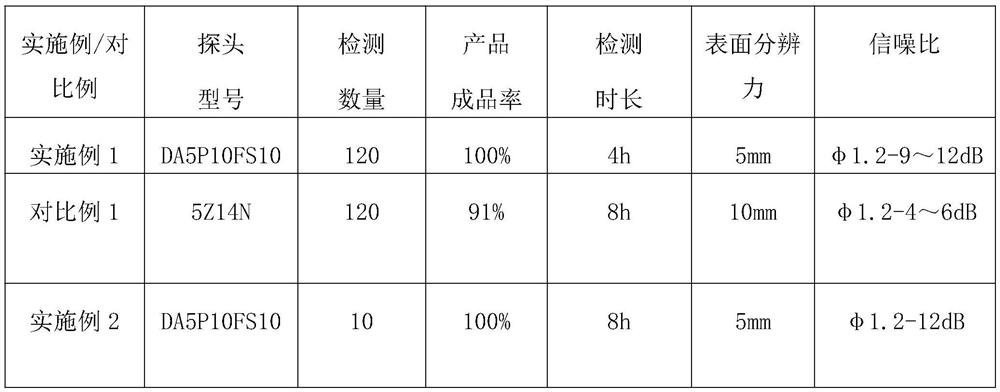

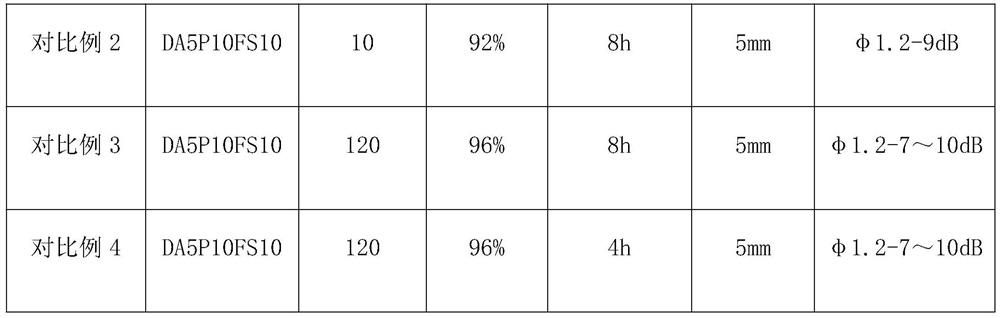

Embodiment 1

[0039] The present invention will be described in detail below by taking the rare earth magnesium alloy extruded sheet (specification 25*70*315, unilateral machining allowance of 5mm) developed by our company as an example.

[0040] Surface cleaning of the inspected parts: Use clean non-woven fabrics to clean the surface stains, attachments and other unfavorable factors that affect the incidence of sound energy along the direction of the extrusion flow line on the surface of the plate. The cleaning standard is no obvious dust, clean and tidy.

[0041] In this example, Olympus EPOCH 650 ultrasonic flaw detector (providing a 0-25MHZ frequency band) is used. The probes are DA5P10FS10 double crystal straight probes and 5Z14N single crystal straight probes, and the couplant is No. 46 anti-wear hydraulic oil.

[0042]The flat-bottom hole comparison test block for flaw detection is designed to have a buried depth of 5mm, 10mm, 15mm, 20mm, and 25mm; the hole diameter is φ2.0mm, and oth...

Embodiment 2

[0048] The present invention will be described in detail below by taking the rare earth magnesium alloy extruded sheet (specification 10*175*1800 machining allowance of 2mm) developed by our company as an example.

[0049] Surface cleaning of the inspected part: Use clean non-woven fabrics to clean the surface stains, attachments and other unfavorable factors that affect the incidence of sound energy along the direction of the extrusion flow line on the surface of the plate. The cleaning standard is no obvious dust, clean and tidy.

[0050] In this example, Olympus EPOCH 650 ultrasonic flaw detector (providing a 0-25MHZ frequency band) is used. The probes are DA5P10FS10 double crystal straight probes and 5Z14N single crystal straight probes, and the couplant is No. 46 anti-wear hydraulic oil.

[0051] The flat-bottom hole test block that has been designed and manufactured in Example 1 is selected as the test block for flaw detection, with a buried depth of 5mm, 10mm, 15mm, 20mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com