Spent fuel post-processing method based on uranium cluster compound

A technology for clustering and spent fuel, applied in reactor fuel elements, recycling technology, reducing greenhouse gases, etc., can solve the problems of reducing separation efficiency, uranium and plutonium purification coefficient, etc., and achieve good economic benefits, simple process, and low corrosiveness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

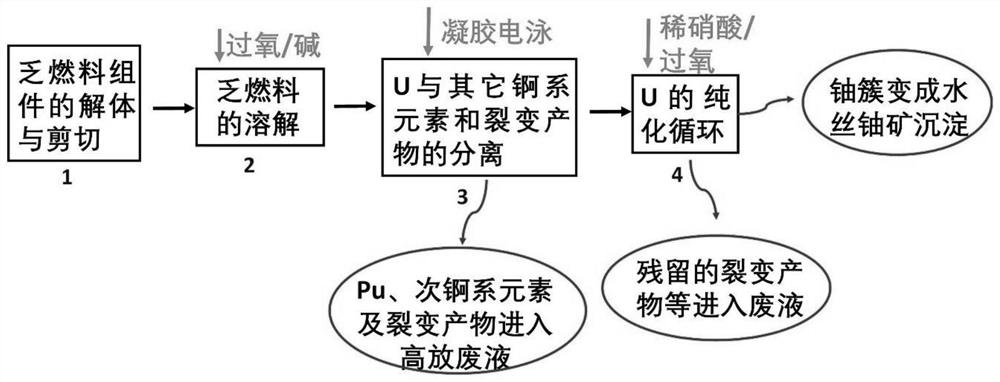

[0043] A method for reprocessing spent fuel based on uranium clusters, comprising the following steps:

[0044] S1. Dismantling the spent fuel assembly and cutting it into small fuel rods;

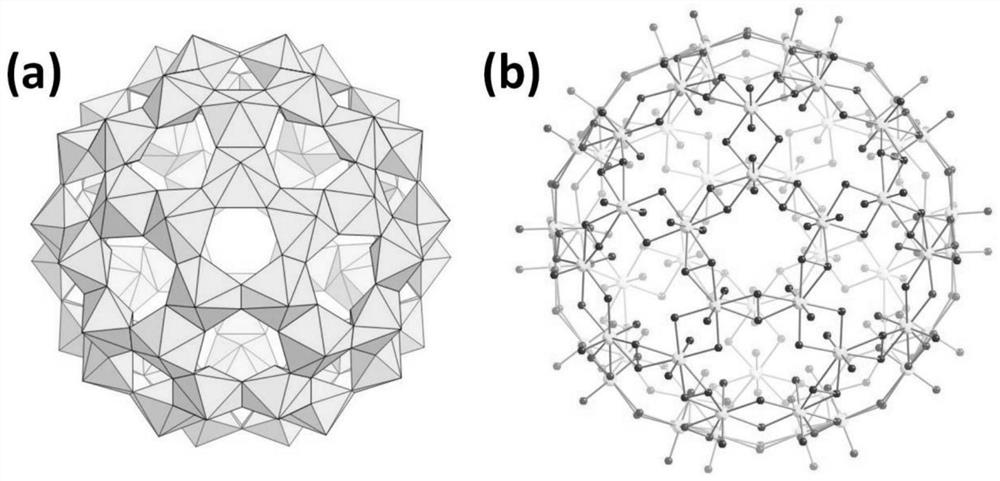

[0045] S2. Use hydrogen peroxide and ammonia water to dissolve spent fuel; the solution is hydrogen peroxide with a mass concentration of 30%, and the concentration of ammonia water is 4mol / L. The two are mixed at a volume ratio of 1:1, and hydrogen peroxide can be in excess; add the treated spent fuel Fuel, UO in spent fuel 2 Under the oxidation of hydrogen peroxide, it dissolves into uranyl ions. Ensure that the concentration of uranyl ions after dissolution is controlled at 0.5mol / L; uranyl ions are coordinated with peroxides and hydroxides to form uranyl peroxide clusters in the form of giant anions; Pu, some minor actinides and fission products dissolve After the alkaline solution, with Pu 4+ 、Cs + 、MoO 4 2- In the form of simple inorganic cations or anions, insoluble actinide p...

Embodiment 2

[0050] A method for reprocessing spent fuel based on uranium clusters, comprising the following steps:

[0051] S1. Dismantling the spent fuel assembly and cutting it into small fuel rods;

[0052] S2, using hydrogen peroxide and Na 2 CO 3 To dissolve spent fuel, the solution is hydrogen peroxide with a concentration of 30%, Na 2 CO 3 The concentration of the solution is 3mol / L, and the two are mixed at a volume ratio of 1:1, and the hydrogen peroxide can be appropriately excessive; the treated spent fuel is added, and the UO in the spent fuel 2 Under the oxidation of hydrogen peroxide, it dissolves into uranyl ions, ensuring that the concentration of uranyl ions after dissolution is controlled at 2mol / L; uranyl ions are coordinated with peroxide and hydroxide to form uranyl peroxide clusters in the form of giant anions ; After Pu, some minor actinides and fission products are dissolved in the alkaline solution, the Pu 4+ 、Cs + 、MoO 2- It exists in the form of simple in...

Embodiment 3

[0057] A method for reprocessing spent fuel based on uranium clusters, comprising the following steps:

[0058] S1. Dismantling the spent fuel assembly and cutting it into small fuel rods;

[0059] S2. Use hydrogen peroxide and NaOH to dissolve spent fuel. The solution is hydrogen peroxide with a concentration of 30%, and the concentration of NaOH solution is 2.5mol / L. Add treated spent fuel, UO in spent fuel 2 Under the oxidation of hydrogen peroxide, it dissolves into uranyl ions, ensuring that the concentration of uranyl ions after dissolution is controlled at 1mol / L; uranyl ions are coordinated with peroxide and hydroxide to form uranyl peroxide clusters in the form of giant anions , after Pu, some minor actinides and fission products are dissolved in the alkaline solution, the Pu 4+ 、Cs + 、MoO 2- In the form of simple inorganic cations or anions, insoluble actinide products and fission products are properly stored as high-level solid waste;

[0060] S3. Using the dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com