Method for destructing oxalic acid in plutonium oxalate sediment mother solution

A technology for precipitating mother liquor and plutonium oxalate, applied in the direction of improving process efficiency, etc., can solve problems such as reduction of current efficiency and operation safety, reduction of current efficiency and electrolysis speed, and industrial application limitations, so as to improve operation safety and electrolysis speed Fast and avoid the effect of anode passivation phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for destroying oxalic acid in plutonium oxalate precipitation mother liquor, the method comprises the following steps:

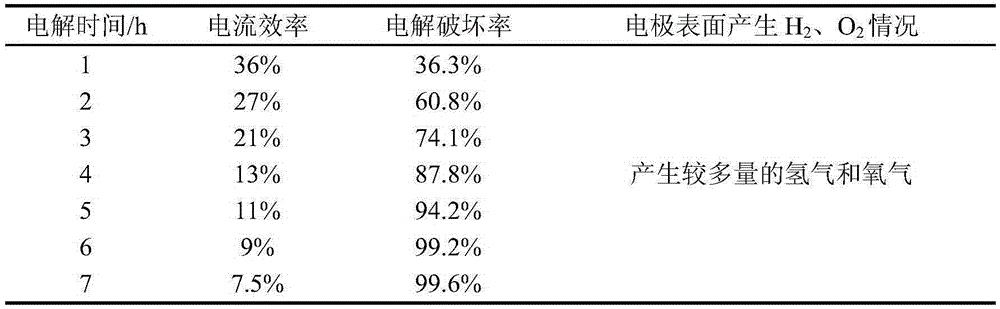

[0022] The plutonium oxalate precipitation mother liquor in the plutonium oxalate precipitation mother liquor in the 100ml mixed solution that is formed by the solution of 0.05mol / L oxalic acid, 2mol / L nitric acid and 100mgPu / L simulates aftertreatment, and this precipitation mother liquor joins in the electrolytic cell that volume is 130ml, in Add two areas of 4cm to the electrolytic cell 2 The platinum-plated titanium electrode is used as the cathode and the anode, and the two electrodes are connected to a DC power supply that can be reversed periodically; the operating voltage of the power supply is set to 1.4V, and the cycle time interval of the reverse cycle is 10 seconds. A magnetic stirrer was used to stir the solution during electrolysis.

[0023] The concentration of oxalate in the solution was sampled and analyzed every 20 minutes,...

Embodiment 2

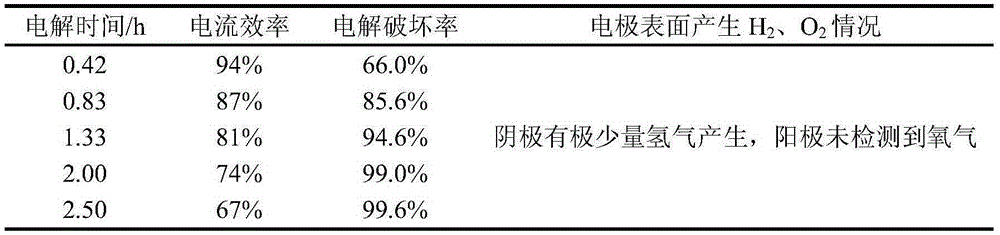

[0032] The difference from Example 1 is that the operating voltage of the power supply is set to 1.0V, the cycle of the DC power supply reversal is 7s, and both the cathode and the anode are platinum electrodes.

Embodiment 3

[0034] The difference from Example 1 is that the operating voltage of the power supply is set to 1.2V, the cycle of the reverse DC power supply is 8s, the cathode is a platinum electrode, and the anode is a platinum-plated titanium electrode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com