Multilayer magnetic core film based on amorphous CoNiFe and preparation method thereof

An amorphous and magnetic core technology, applied in the field of multilayer magnetic core film and its preparation, can solve the problems of non-magnetic insulating oxides, unfavorable film soft magnetic properties, reducing material saturation magnetization, etc., and achieve high saturation magnetization , high anisotropy field, the effect of improving resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

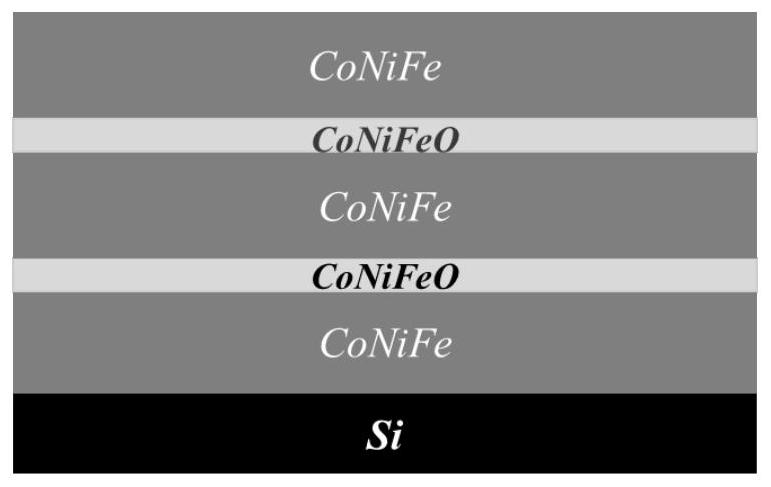

[0030] A preparation method of a multilayer magnetic core film based on amorphous CoNiFe, specifically comprising the following steps:

[0031] Step 1. Wash the silicon substrate with acetone and alcohol in turn to remove organic matter, then ultrasonically oscillate in deionized water for 5 min, and dry with nitrogen for use;

[0032] Step 2. Use magnetron sputtering to prepare an amorphous CoNiFe magnetic layer on the silicon substrate cleaned in step 1:

[0033] Place the cleaned silicon substrate substrate and target in step 1 in a magnetron sputtering chamber, where the target is Co 65 Ni 12 Fe 23 Alloy target, the diameter of the target is 74mm, and it is a 3-inch target; Argon gas is introduced into the magnetron sputtering chamber, and the sputtering power is 0.25W / cm 2, Under the condition of sputtering gas pressure of 0.13Pa, magnetron sputtering method was used to prepare amorphous CoNiFe magnetic layer with thickness of 50-200nm; during sputtering, anisotropic f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com