Negative electrode material, preparation method thereof and battery

A technology of negative electrode material and negative electrode sheet, which is applied in the direction of battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor fast charging performance, achieve the effect of improving electrical performance, excellent electrical conductivity, and improving the first Coulombic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

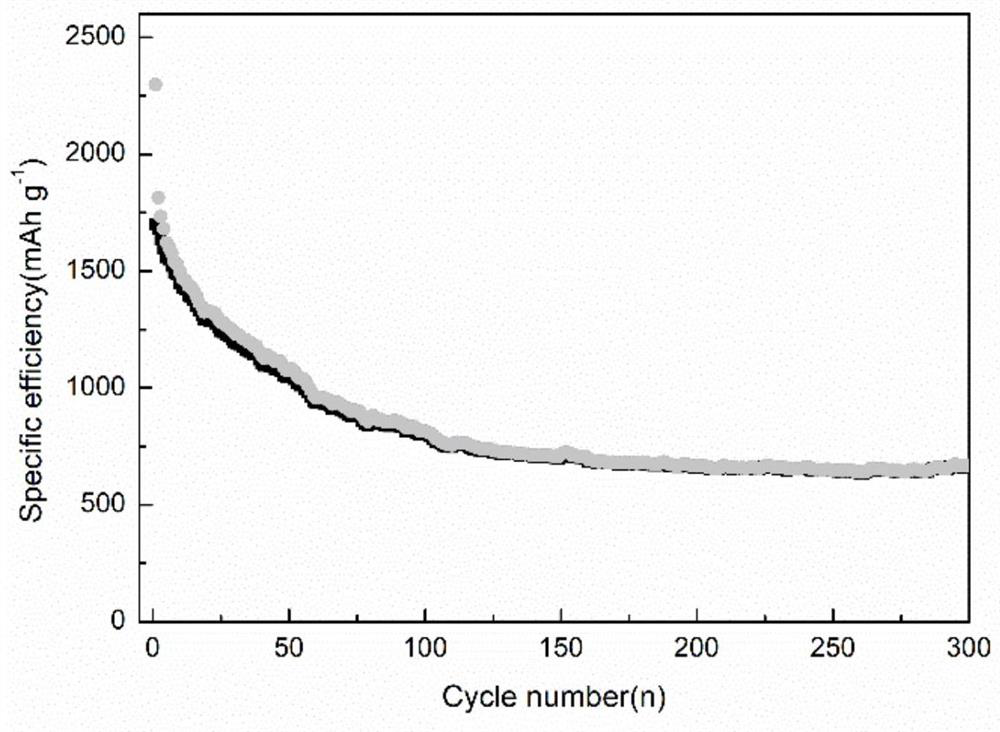

Image

Examples

preparation example Construction

[0049] Correspondingly, an embodiment of the present invention also provides a method for preparing a negative electrode material, comprising:

[0050] Step 1, the carbon source is added to deionized water and then placed in a stirring device (such as a magnetic stirrer) to stir evenly to obtain a first suspension, and the obtained first suspension is placed at 0°C for constant temperature ultrasonic dispersion for 2- 3h;

[0051] Step 2, adding polyvinylidene fluoride into the first suspension, the mass ratio of polyvinylidene fluoride and carbon source is 1-2:1, and then stirring until the polyvinylidene fluoride is completely dissolved;

[0052] Step 3, adding the doping element source to the first suspension after adding the polyvinylidene chloride, the mass ratio of the doping element source and the carbon source is 3-5:1, and then stirring for 1-2 h to obtain the second suspension;

[0053] Step 4: Add the silicon source into the second suspension, the mass ratio of th...

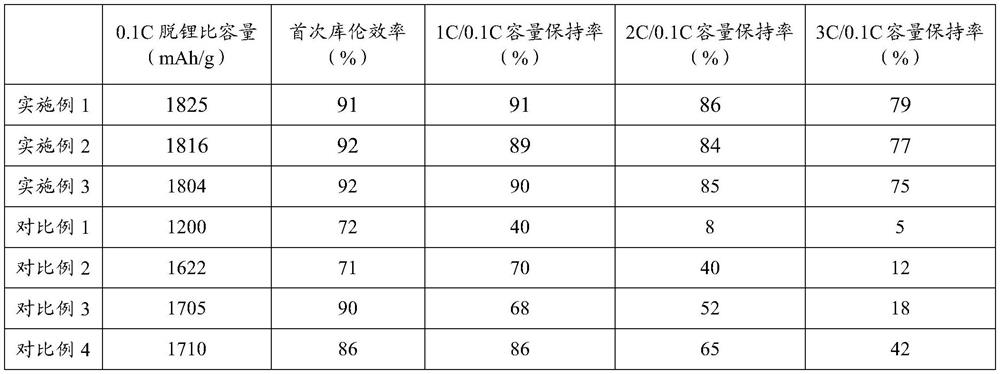

Embodiment 1

[0063] A preparation method of a negative electrode material, comprising:

[0064] Step 1, adding graphene oxide into deionized water and then placing it in a magnetic stirrer to stir evenly to obtain a first suspension, and placing the obtained first suspension at 0°C for constant temperature ultrasonic dispersion for 2h;

[0065] Step 2, adding polyvinylidene fluoride to the first suspension, the mass ratio of polyvinylidene fluoride and graphene oxide is 1:1, and then stirring until the polyvinylidene fluoride is completely dissolved;

[0066] Step 3, adding melamine to the first suspension after adding polyvinylidene chloride, the mass ratio of melamine and graphene oxide is 3:1, then stirring for 1h to obtain the second suspension;

[0067] Step 4, adding silicon oxide to the second suspension, the mass ratio of silicon oxide and graphene oxide is 5:1, then stirring for 1h, and then performing ultrasonic treatment for 0.5h under the condition of heating in a water bath to...

Embodiment 2

[0070] A preparation method of a negative electrode material, comprising:

[0071] Step 1, adding graphene oxide into deionized water and then placing it in a magnetic stirrer to stir evenly to obtain a first suspension, and placing the obtained first suspension at 0°C for constant temperature ultrasonic dispersion for 3h;

[0072] In step 2, polyvinylidene fluoride is added to the first suspension, the mass ratio of polyvinylidene fluoride and graphene oxide is 2:1, and then the polyvinylidene fluoride is stirred until the polyvinylidene fluoride is completely dissolved;

[0073] Step 3, adding melamine to the first suspension after adding polyvinylidene chloride, the mass ratio of melamine and graphene oxide is 5:1, then stirring for 2h to obtain the second suspension;

[0074] Step 4, adding silicon oxide into the second suspension, the mass ratio of silicon oxide and graphene oxide is 10:1, then stirring for 0.5-1h, and then performing ultrasonic treatment for 0.5h under t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com