Capacitive sensor interface circuit with high-precision input common-mode control

A capacitive sensor and interface circuit technology, which is applied in logic circuit interface devices, logic circuit connection/interface layout, amplifiers with semiconductor devices/discharge tubes, etc., can solve the problem of reducing the effective amplitude of excitation voltage, reducing sensor sensitivity, etc. problem, to achieve the effect of reducing the area, increasing the output swing, and increasing the output swing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical features, circuit structure, functions and usage scenarios of the present invention intuitive and easy to understand, the present invention will be further described below with reference to the drawings. "connection" should be understood in a broad sense.

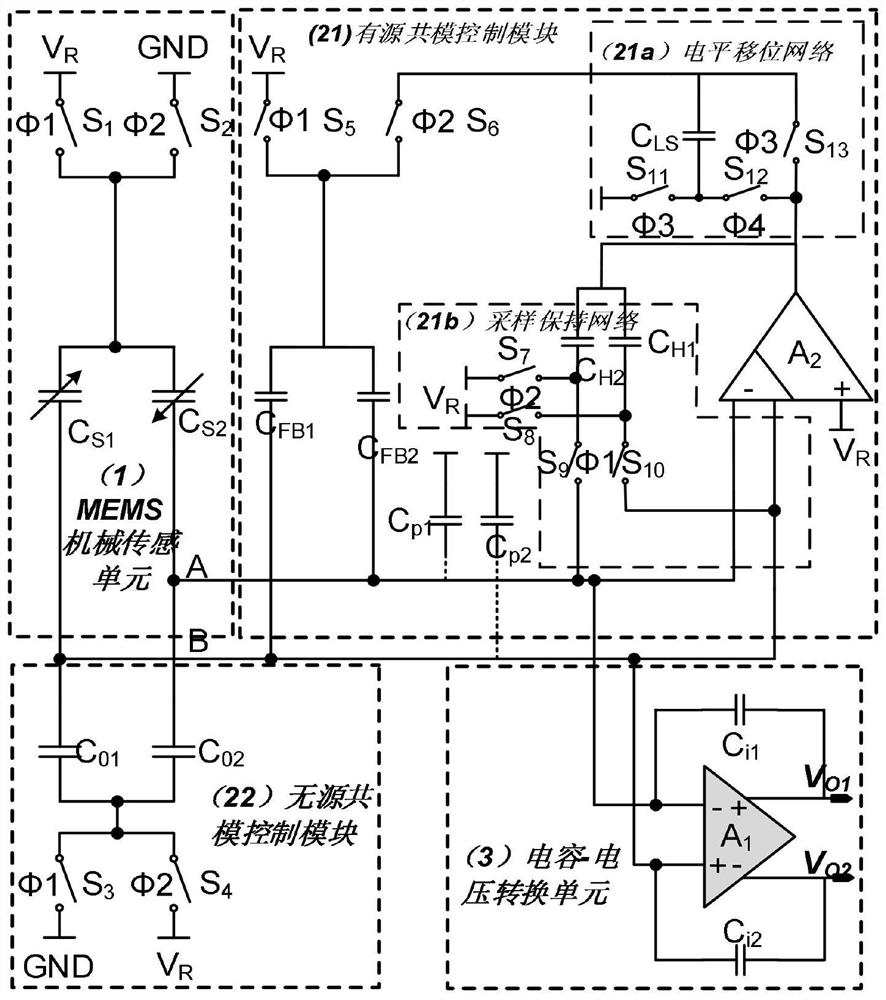

[0026] refer to figure 1 , the capacitive sensor interface circuit with high-precision input common mode control of the present invention includes a MEMS mechanical sensing unit 1, a capacitance-voltage conversion unit 3, a square wave signal generating unit 4, and is characterized in that it also includes an input common mode control unit 2 ;

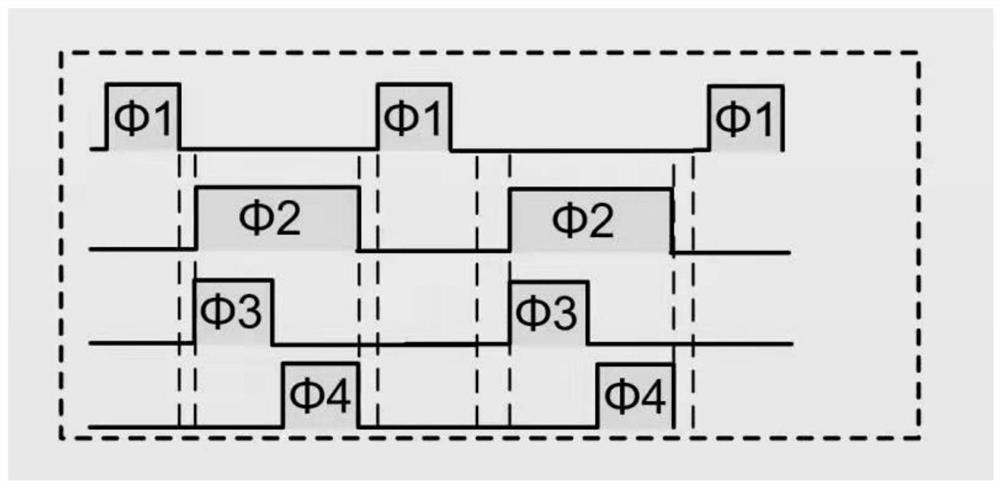

[0027] The MEMS mechanical sensing unit 1 is used to convert the external acceleration signal into the variation of the MEMS mechanical capacitance. The MEMS mechanical sensing element 1 is driven by the square wave signals Φ1 and Φ2 generated by the square wave signal generating unit 4 to generate sensor charges. Signals A and B, the sensor c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com