Multi-pulse-width composite printed circuit board laser processing device

A printed circuit board and laser processing technology, which is applied in the direction of manufacturing tools, metal processing equipment, laser welding equipment, etc., can solve the problems of high equipment cost and low drilling efficiency, improve processing quality, improve drilling efficiency, The effect of ensuring power stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

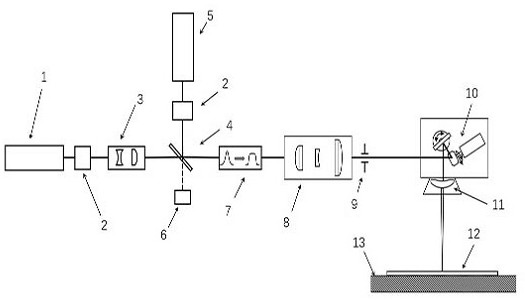

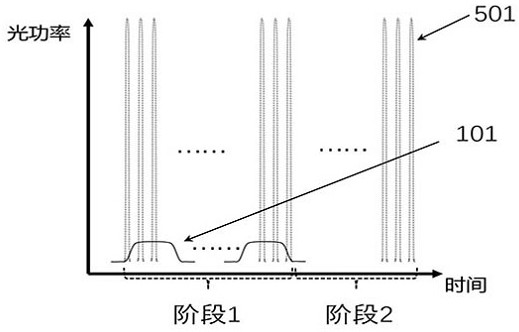

[0036] like Figure 1 to Figure 3 The shown multi-pulse width composite printed circuit board laser processing device includes nanosecond pulse laser 1, ultrafast laser 5, manual variable magnification mirror group 3, beam combiner 4, beam shaper 7, automatic variable magnification mirror Group 8, aperture regulator 9, galvanometer 10, field mirror 11 and translation stage 13; optical isolators 2 are provided between the nanosecond pulse laser and the manual variable magnification mirror group and between the ultrafast laser and the beam combiner ; The extension direction of the ultrafast laser light path is provided with a light absorber 6 for absorbing the ultrafast light pulses leaked from the beam combiner and the reflected nanosecond light pulses.

[0037] like figure 1 As shown, the optical path is divided into two paths before the beam combiner, figure 1 The middle-level one is provided with nanosecond pulse laser, optical isolator, and manual variable magnification mir...

Embodiment 2

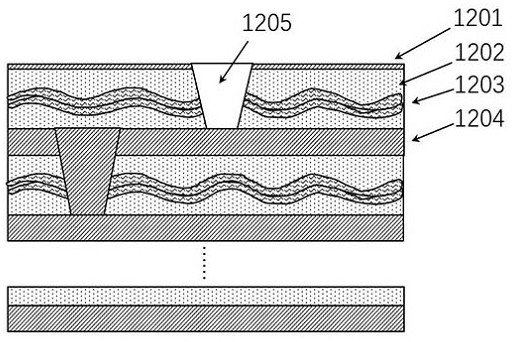

[0063] like Figure 4 As shown, this embodiment also provides a double-table laser processing device. In order to improve production efficiency, common PCB laser drilling machines usually adopt a double-station linkage design, which requires two optical paths on the two stations of the translation table. processing. In terms of cost, it is more cost-effective to split a single ultrafast laser into two channels. At the same time, since the peak power of the ultrafast laser itself is high enough, the peak power of each channel after splitting into two channels is also sufficient to destroy the surface of the material; therefore In this embodiment, the ultrafast laser is divided into two paths by a beam splitter 14 after passing through the optical isolator and the manual variable magnification lens group. The beam splitter can use a polarizing beam splitting prism, and the beam splitting energy ratio can be adjusted by finely adjusting the angle of the beam splitting prism. How...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com