Filter line grid with tungsten sputtered on surface and hafnium oxide deposited in micropores and manufacturing method

A technology of hafnium dioxide and a manufacturing method, which is applied in sputtering coating, instruments used for radiation diagnosis, gaseous chemical plating, etc., to achieve the effects of improving primary radiation transmittance, good anti-scattering performance, and regular arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific content of the present invention is further described below:

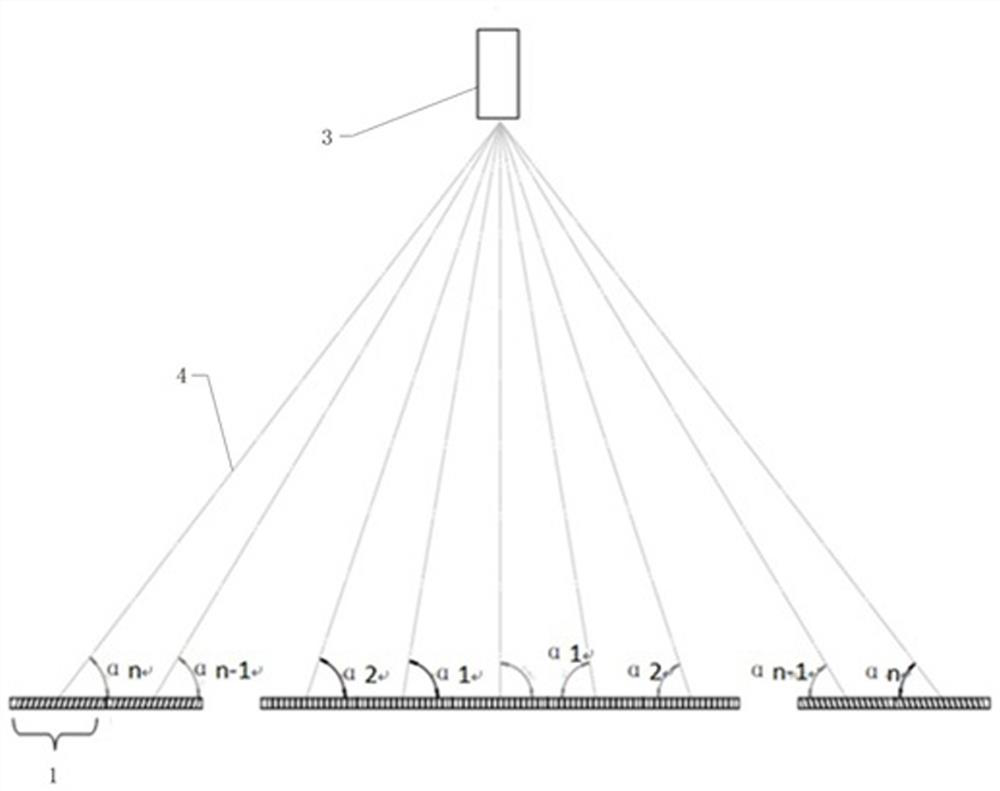

[0040] The invention relates to a surface sputtering tungsten with magnetron sputtering tungsten and atomic layer deposition of hafnium dioxide in a microporous channel, and a filter grid for depositing hafnium dioxide in the microporous channel and a manufacturing method.

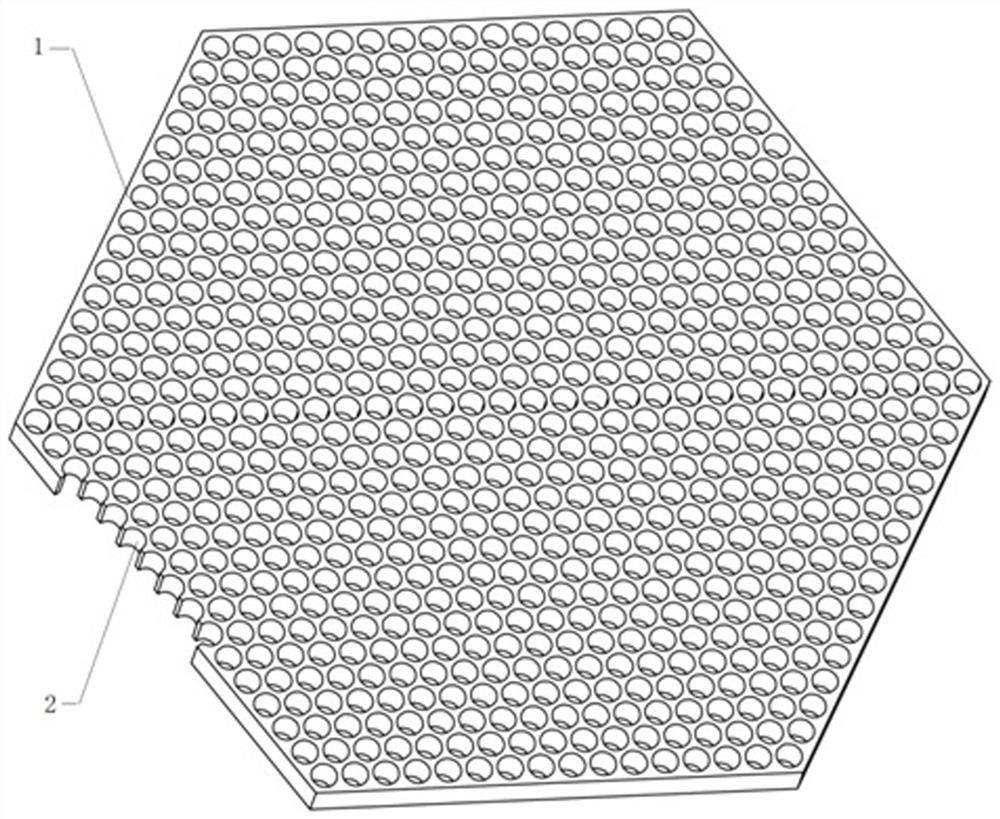

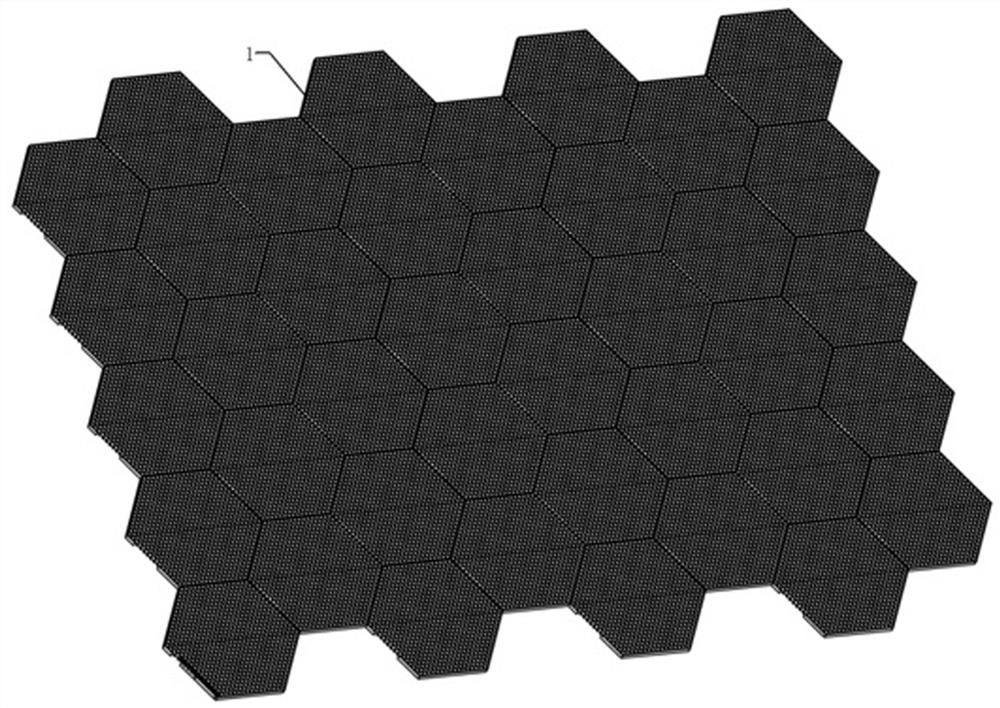

[0041] The filter grid with tungsten sputtering on the surface and hafnium dioxide deposited in the micropores is made up of multiple high lead equivalent glass micropore array units, and magnetron sputtering tungsten on the upper and lower surfaces, in the micropore channel Structure of hafnium dioxide by atomic layer deposition.

[0042] According to the physical properties of metal tungsten, the manufacturing method of plating tungsten on the surface of the filter grid can effectively shield the incidence of X-rays in the non-microporous channel part of the surface of the filter grid, and reduce the interference of X-rays...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com