Non-cracking high-wear-resistance and corrosion-resistance nickel-based composite material and preparation method thereof

A composite material and wear-resistant technology, applied in the fields of laser cladding, laser thermal spraying, and laser additive manufacturing, it can solve the problems of complex preparation process, poor plastic toughness, etc. The effect of the more complex preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

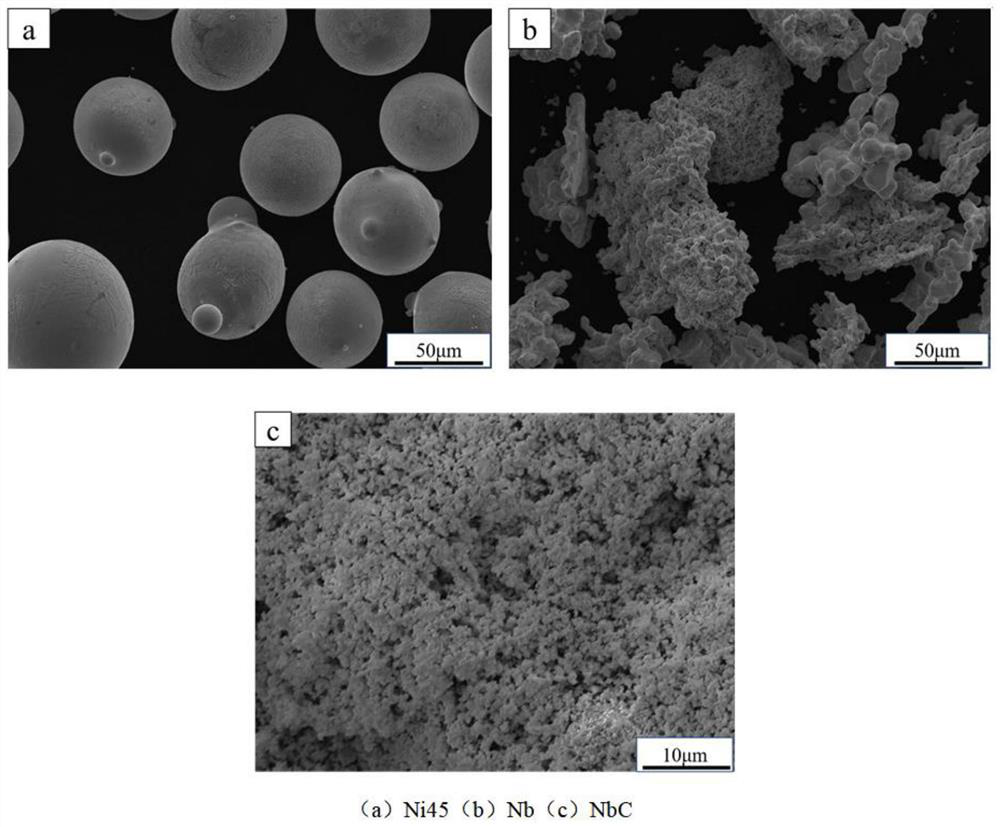

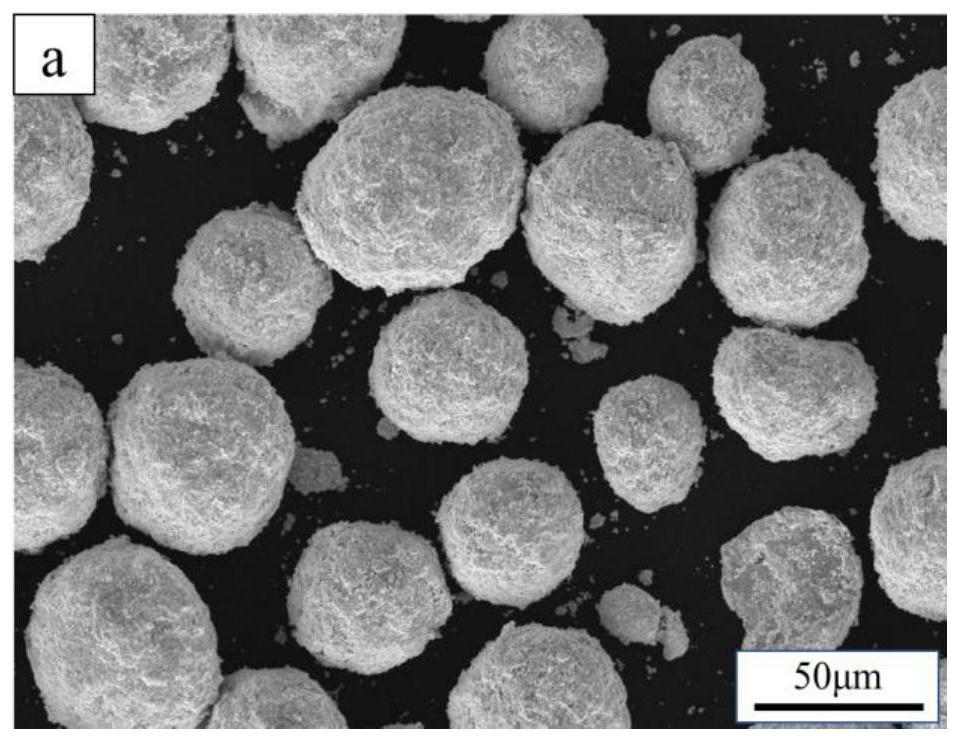

[0028] refer to figure 1 and figure 2 As shown in the figure, the embodiment of the present invention provides a nickel-based composite material with high wear resistance and corrosion resistance without cracking. Powder and reinforced ceramic phase powder, wherein the powder particle size of the nickel-based alloy powder is 10-150 μm, the single particle size of the niobium powder is 4-6 μm, the aggregate size of the niobium powder is 10-150 μm, and the reinforced ceramic phase powder includes carbonization In at least one of the niobium powder and the niobium boride powder, the single particle size of the reinforced ceramic phase powder is 1-4 μm, and the aggregate size of the reinforced ceramic phase powder is 10-150 μm. The nickel-based alloy powder includes, but is not limited to, nickel 45, nickel 40, nickel 50, nickel 55, nickel 60, etc., which is not limited in the embodiment of the present invention.

[0029] In the embodiment of the present invention, the brittle ...

Embodiment 2

[0033] refer to figure 1 and figure 2 As shown in the figure, the embodiment of the present invention provides a nickel-based composite material with high wear resistance and corrosion resistance without cracking. Powder and niobium carbide powder, wherein the nickel-based alloy powder has a powder particle size of 10 to 150 μm, a single particle size of the niobium powder is 4 to 6 μm, and the niobium powder has an aggregate size of 10 to 150 μm. The single particle size of the niobium powder is 1-4 μm, and the aggregate size of the niobium carbide powder is 10-150 μm.

[0034] By adding a certain proportion of niobium and niobium carbide to the nickel-based alloy powder, niobium is a strong carbide forming element, and it will preferentially combine with carbon to form niobium carbide in the molten pool, avoiding the formation of coarse carbides, and at the same time, niobium carbide has lower The Gibbs free energy of the alloy will preferentially grow in the molten pool,...

Embodiment 3

[0036] The embodiment of the present invention provides a nickel-based composite material with high wear resistance and corrosion resistance without cracking. The ceramic phase powder, wherein the powder particle size of the nickel-based alloy powder is 10-150 μm, the single particle size of the tantalum powder is 4-6 μm, the aggregate size of the tantalum powder is 10-150 μm, and the strengthened ceramic phase powder includes tantalum carbide powder and In at least one of the tantalum boride powders, the single particle size of the reinforced ceramic phase powder is 1-4 μm, and the aggregate size of the reinforced ceramic phase powder is 10-150 μm.

[0037] In the present invention, a certain proportion of tantalum, tantalum carbide or tantalum boride is added to the nickel-based alloy powder. Tantalum is a strong carbide forming element, and it will preferentially combine with carbon or boron in the molten pool to form tantalum carbide or tantalum boride, so as to avoid The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com