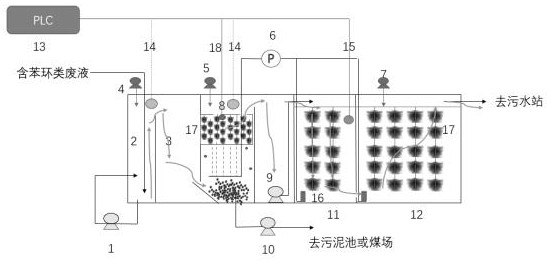

Device and method for treating waste liquid containing benzene ring substances

A technology of waste liquid treatment and treatment method, which is applied in the direction of gaseous effluent wastewater treatment, biological water/sewage treatment, chemical instruments and methods, etc. It can solve problems such as abnormal operation and sensitive activated sludge, and achieves a small footprint , high degree of automation and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

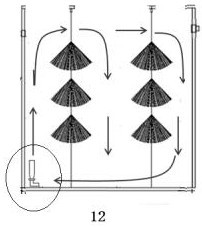

Method used

Image

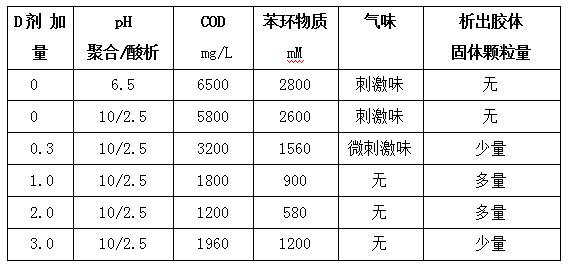

Examples

Embodiment

[0047] Manufacture of Polymerization Accelerators

[0048] Raw materials used in the invention:

[0049] (1) Sodium Hexametaphosphate (CAS # 10124-56-8)

[0050] (2) Glutathione Reduced Form (CAS # 70-18-8)

[0051] (3) Glycerol dehydrogenase (EC 1.1.1.6; 50 U / mg)

[0052] (4) Ethylenediaminetetraacetic acid (CAS#60-00-4)

[0053] (5) Sodium Peroxydisulfate (CAS # 7775-27-1)

[0054] (6) Purified water (ion-exchanged water, resistivity 1 MΩ·cm)

[0055] Inventive polymerization accelerator configuration steps:

[0056] 1) Add 1200g of sodium hexametaphosphate, 200mg of reduced glutathione and 10mg of glycerol dehydrogenase to 4000g of purified water, stir and mix, and refrigerate for 3 days under normal pressure at 0 to 5°C to obtain a mixed solution (W);

[0057] 2) Add 600g of mixed solution (W), 2500g of sodium peroxodisulfate, and 40g of ethylenediaminetetraacetic acid to 16860g of pure water, stir and mix, and place incubation at room temperature (about 20°C) under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com