Super-hydrophobic spongy three-dimensional conductive composite material as well as preparation method and application thereof

A conductive composite material, super-hydrophobic sponge technology, applied in sustainable manufacturing/processing, climate sustainability, chemical industry, etc., can solve problems such as limited application, limited hydrophobic corrosion resistance, flexible electronic device interference, etc. Simple preparation process, overcoming poor flexibility, and broadening the effect of application environment and field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

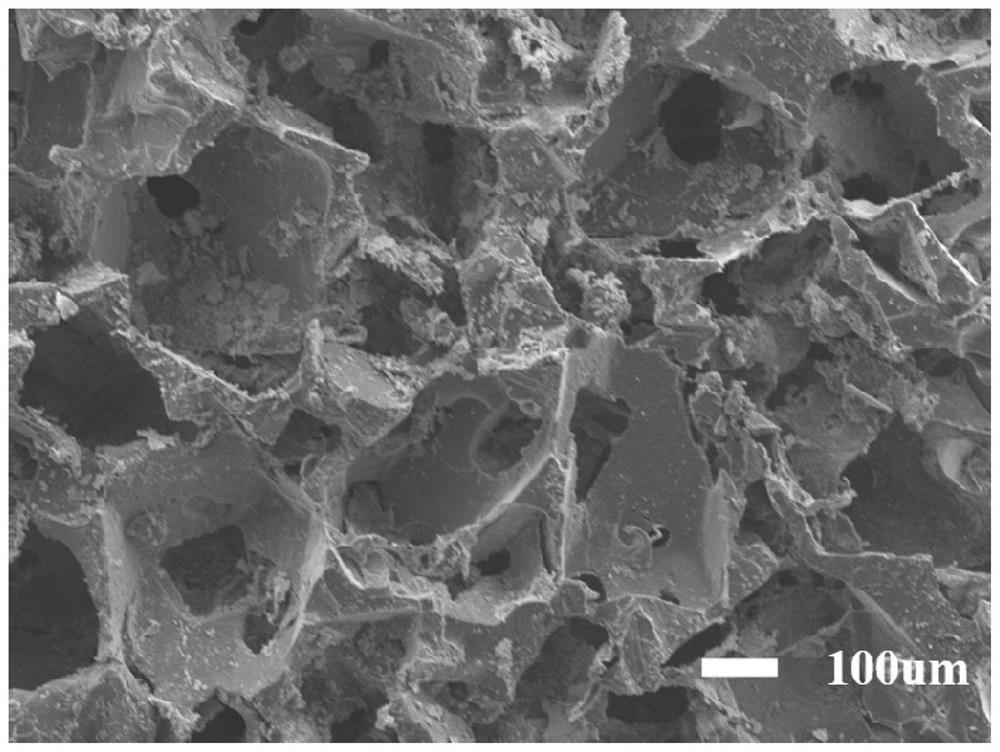

[0035] Step 1. Stir PDMS, carbonyl iron powder and curing agent in a container in a ratio of 10:5:1 for 10 minutes to mix well. Then, the sugar cubes are put into the prepared mixed liquid, and the mixed liquid is filled with the internal pores of the sugar cubes by vacuum impregnation at room temperature, and then placed in an oven at 90° C. for curing for 2 hours to obtain a cured composite material.

[0036] Step 2. Take the cured composite material out of the oven, remove the excess composite material on the sugar cube surface with a blade, and place it in a beaker filled with deionized water for 8 hours to completely dissolve the sugar cube; It was placed in an oven at 60° C. to dry for 12 hours to obtain a porous cured composite material.

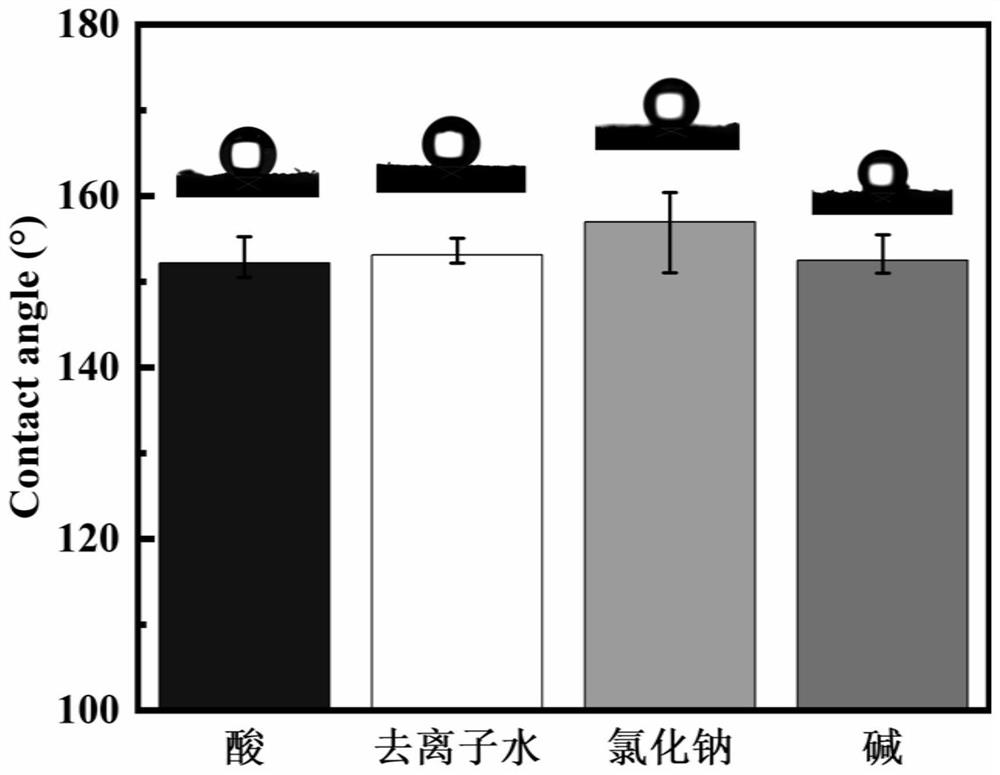

[0037] Step 3. Dissolve STA and SEBS in THF, prepare a mixed solution with a concentration of STA of 5 wt% and a concentration of SEBS of 1 wt%, and place the solution in an ultrasonic cleaner for 30 minutes.

[0038] Step 4. After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com