Elastic ring type damper with metal rubber layer

A technology of metal rubber and elastic rings, which is applied to the rigid support of bearing components, flexible bearings, machines/engines, etc., can solve the problems of reduced installation space, strength and stiffness design, abnormal vibration of rotors, and instability of oil film oscillations, etc., to achieve improvement Dynamic characteristics, reduce work damage, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

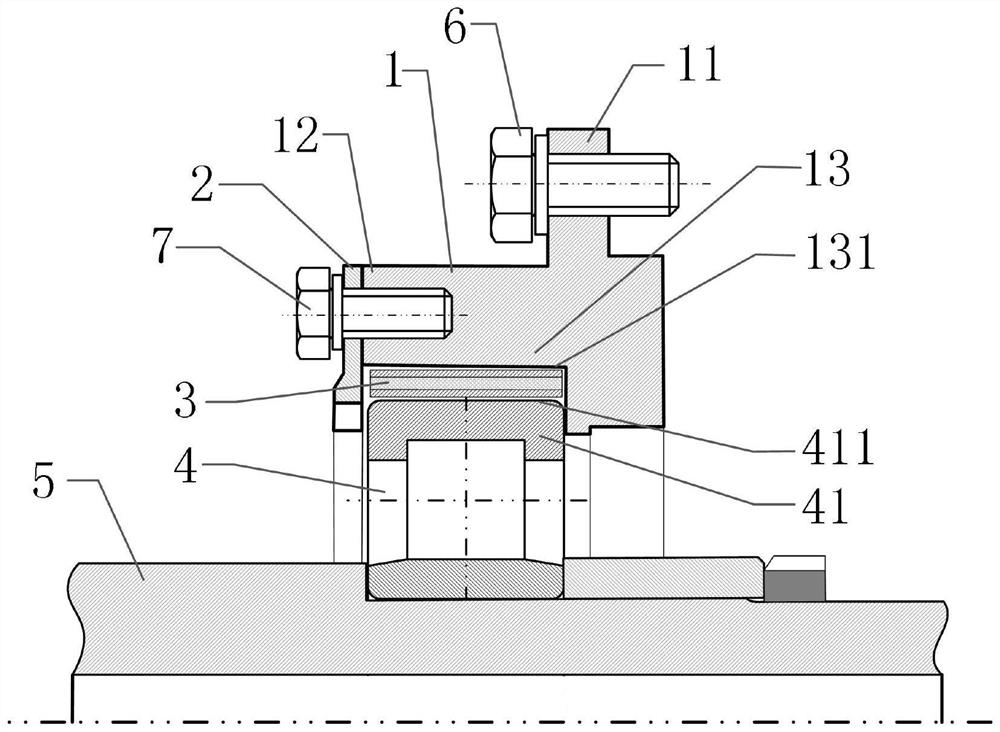

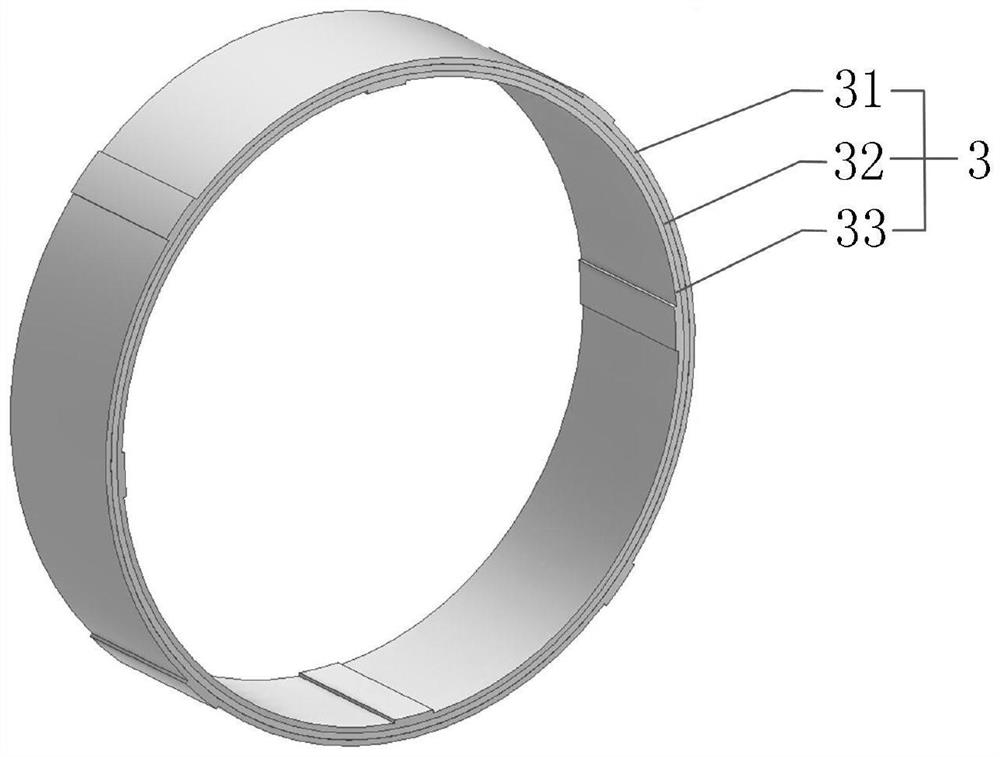

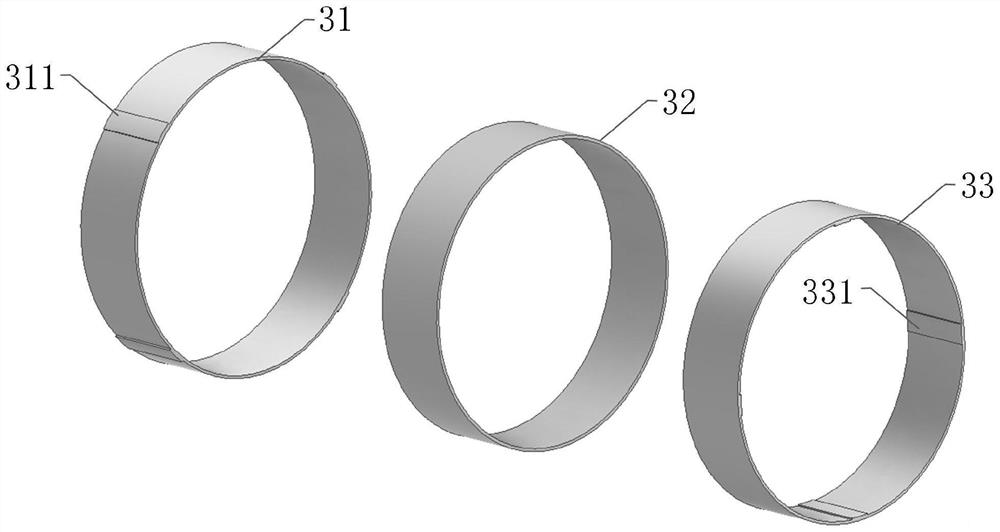

[0029] refer to figure 1 , Figure 2-a , Figure 2-b , an elastic ring damper with a metal rubber layer of the present invention includes a rigid bearing seat 1, an axial baffle 2 and an elastic ring 3 with a metal rubber layer; position for rotor system vibration control. The rigid bearing seat 1 includes a fixed mounting edge 11 , a baffle mounting edge 12 and a bearing mounting hole 13 . The elastic ring 3 includes an elastic outer ring 31 with an outer boss 311 , an elastic inner ring 33 with an inner boss 331 , and a metal rubber layer 32 between the inner and outer rings. The rigid bearing seat 1 is connected with the external load-bearing member through the first bolt 6 to realize its fixed installation. The bearing outer ring 41 of the fulcrum bearing 4 is installed in the bearing installation hole 13 of the rigid bearing seat 1; the diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com