Low-corrosivity peracetic acid disinfectant containing wetting agent and preparation method of low-corrosivity peracetic acid disinfectant

A peracetic acid, corrosive technology, applied in the field of low corrosive peracetic acid disinfectant and its preparation, can solve the problems of poor treatment effect of bacterial biofilm, etc., achieve rapid disinfection and sterilization, good effect and high stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

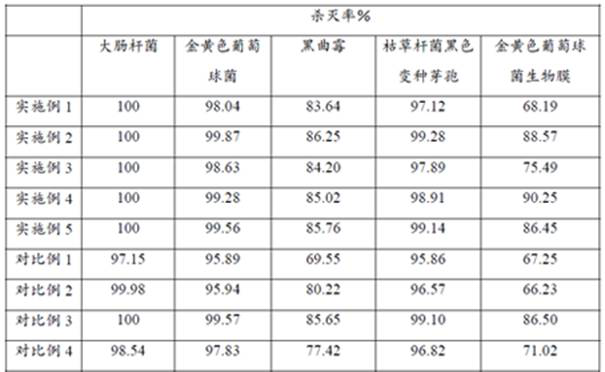

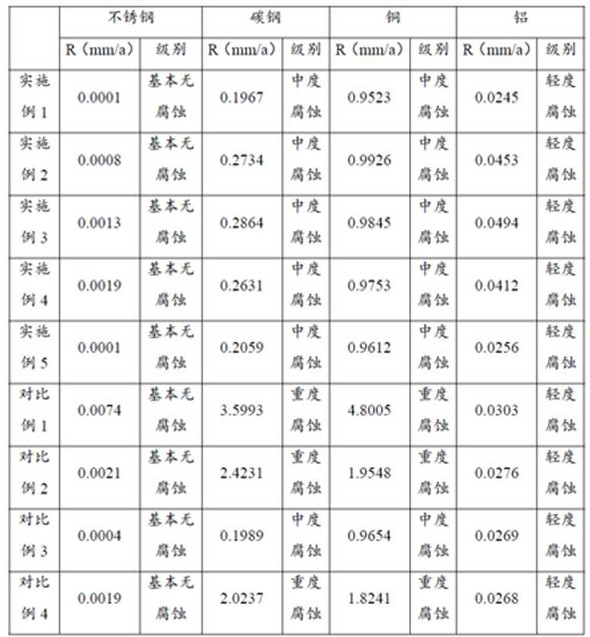

Examples

Embodiment 1

[0022] A peracetic acid disinfectant, calculated by mass percentage, comprising 15% hydrogen peroxide (50% concentration), 40% glacial acetic acid (99% concentration), 0.2% isomeric C10 alcohol polyoxyethylene polyoxypropylene Ether, 2% cetyltrimethylammonium chloride, 0.2% sodium persulfate, 1% 2,6-pyridinedicarboxylic acid, 1% hydroxyethylidene diphosphonic acid, 40.6% water.

[0023] The preparation method of this peracetic acid disinfectant, comprises the steps:

[0024] (1) Weigh hydrogen peroxide, glacial acetic acid, isomeric C10 alcohol polyoxyethylene polyoxypropylene ether, cetyltrimethylammonium chloride, sodium persulfate, 2,6-pyridinedicarboxylic acid, Hydroxyethylidene diphosphonic acid;

[0025] (2) Dissolve sodium persulfate in glacial acetic acid, then add isomeric C10 alcohol polyoxyethylene polyoxypropylene ether to make it dissolve evenly, then add cetyltrimethylammonium chloride, dissolve fully, then add Hydrogen peroxide, mix well, add 2,6-pyridinedicar...

Embodiment 2

[0027] A peracetic acid disinfectant, calculated by mass percentage, comprising 18% hydrogen peroxide (50% concentration), 35% glacial acetic acid (99% concentration), 1% isomeric C10 alcohol polyoxyethylene polyoxypropylene Ether, 1% dodecylguanidine hydrochloride (CAS: 13590-97-1), 1% ammonium persulfate, 0.5% diethylenetriamine pentamethylenephosphonic acid, 1% diethyltrimonium Amine pentaacetic acid, 42.5% water.

[0028] The preparation method is the same as that of Example 1.

Embodiment 3

[0030] A peracetic acid disinfectant, calculated by mass percentage, comprising 20% hydrogen peroxide (50% concentration), 30% glacial acetic acid (99% concentration), 2% isomeric C10 alcohol polyoxyethylene polyoxypropylene Ether, 0.5% dodecylguanidine hydrochloride, 2% potassium persulfate, 1.5% hydroxyethylidene diphosphonic acid, 1% 2,6-pyridinedicarboxylic acid, 43% water.

[0031] The preparation method is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com