Fat emulsion dialysate as well as preparation method and application thereof

A technology of milk dialysate and fat emulsion, which is applied in the field of hemodialysis and can solve the problems of human albumin source and treatment cost limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The second aspect of the present invention provides the preparation method of the fat emulsion dialysate provided by the first aspect of the present invention. On the basis of the known formula of the fat emulsion dialysate, those skilled in the art can select a suitable method to prepare the above fat emulsion dialysate. For example, it may include providing an oil phase and an aqueous phase, mixing and homogenizing the oil phase and the aqueous phase to provide a fat emulsion dialysate. For another example, when mixing and / or homogenizing, the temperature of the system may be 50-90°C, 50-60°C, 60-70°C, 70-80°C, or 80-90°C. For another example, the oil phase and the water phase can be fully mixed by high-speed shearing. 10~20min, 5~10min, 10~12min, 12~14min, 14~16min, 16~18min, 18~20min, 20~25min, or 25~30min. As another example, the homogeneous pressure conditions are 200-1000 bar, 200-400 bar, 400-600 bar, 600-800 bar, or 800-1000 bar. For another example, the homo...

Embodiment 1

[0056] The aqueous and oil phases were prepared separately. Weigh 5.5g soybean oil, 4.5g medium chain triglyceride and 0.15g α-tocopherol, mix and stir to fully dissolve them as oil phase; weigh 0.13g sodium oleate, 0.9g glycerol and a certain mass fraction (0.4, 0.8 , 1, 2 and 3%) egg yolk lecithin was added to a certain volume of solution (water or dialysate), stirred and dispersed uniformly as the water phase. The oil phase is pretreated by high speed shearing. After the temperature of the water phase was raised to 70 °C, the oil phase was slowly injected into the water phase, and sheared for 10 min under the condition of high-speed shearing at a certain speed. The sheared solution is subjected to gradient homogenization (600, 800, 1000, 2 times per gradient) using a high-pressure homogenizer under a pressure of 600-1000 bar to obtain a fat emulsion dialysate. When the fat emulsion dialysate is used for in vitro simulated dialysis, it needs to be used with 5% sodium bicar...

Embodiment 2

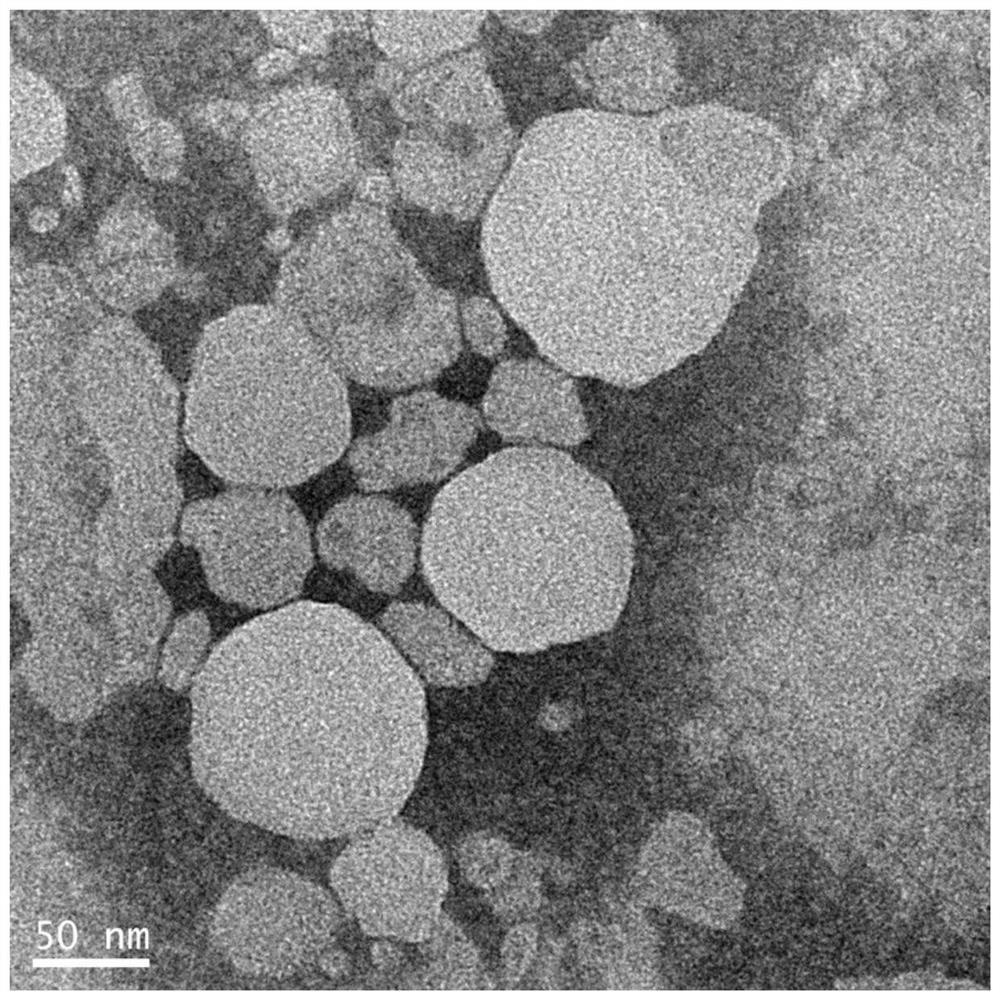

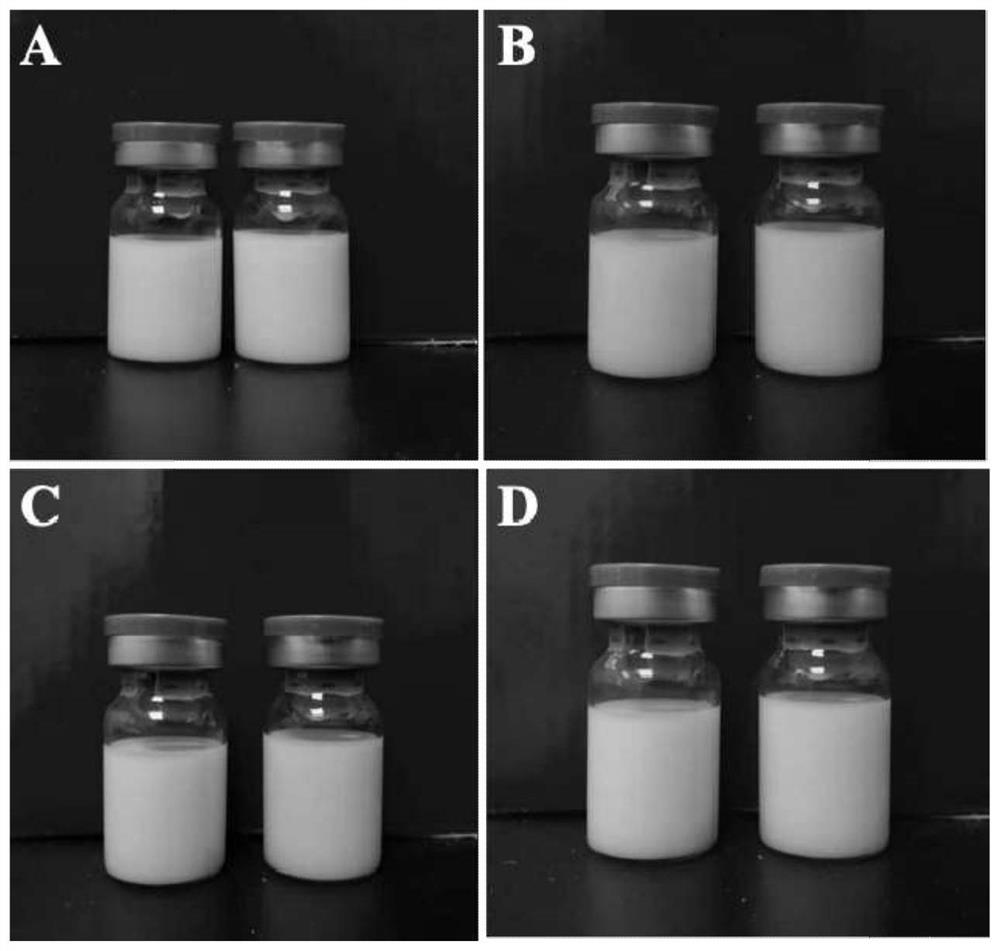

[0058] Malvern particle size analyzer was used to detect the hydration kinetic size of the fat emulsion in the fat emulsion dialysate with different phospholipid contents prepared according to the method described in Example 1. The results are shown in Table 1. The transmission electron microscope was used to observe the fat emulsion with 3% phospholipid content. The surface morphology of the particles, the results are as figure 1 shown. The apparent morphology (stability) of the fat emulsion during standing at room temperature for 21 days is as follows figure 2 As indicated (wherein, A. Day 1; B. Day 4; C. Day 7; D. Day 14).

[0059] Table 1 Different phospholipid content fat emulsion particle size

[0060]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com