Porous ore filter element material and preparation method thereof

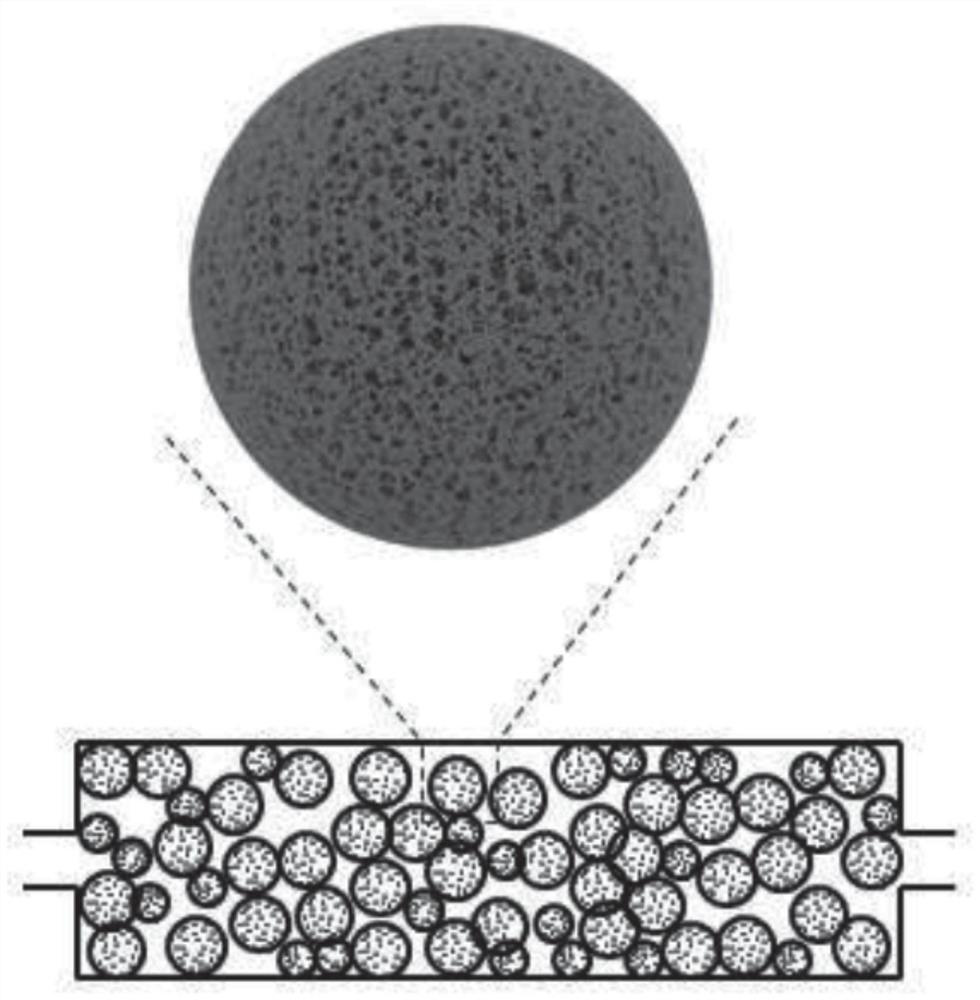

A technology of ore and filter element, which is applied in the field of porous ore filter element material and its preparation, can solve the problems of high cost and complicated preparation process, and achieve the effects of high compressive strength, large specific surface area and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

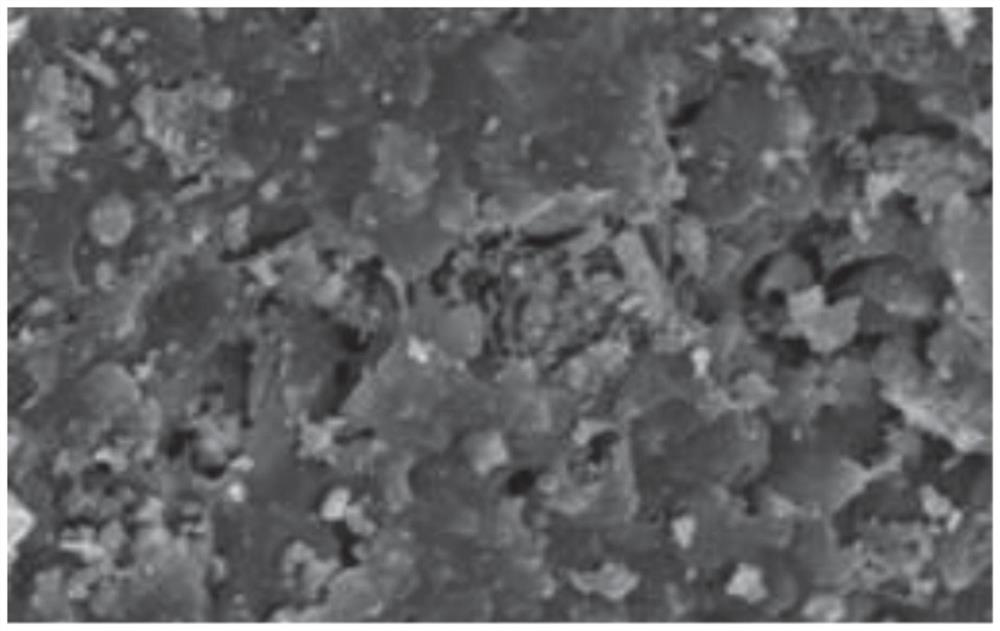

Method used

Image

Examples

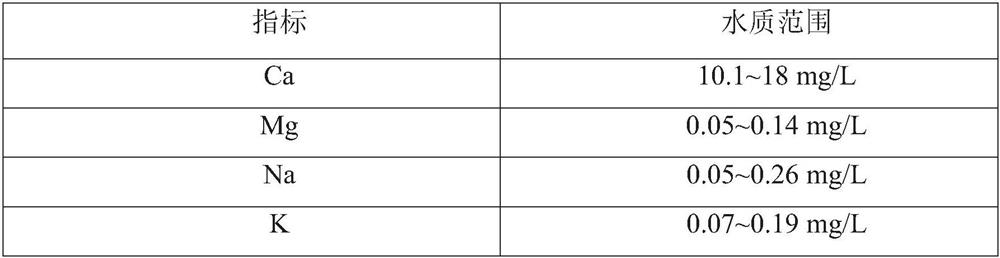

Embodiment 1

[0056] The preparation process of porous ore filter material is as follows:

[0057] Preparation of raw materials: 109.4g of medical stone, 180g of lapis lazuli, 65g of shells, 5g of magnesium ore, 260g of clay, and 64g of ammonium bicarbonate.

[0058] Preparation method: first grind the raw materials into powder in a mixer and pass through a 250-mesh sieve, then humidify and granulate in a granulator, the particle size of the granulated material is controlled at 6-10mm, and then transferred to a 60°C constant temperature drying oven for drying After treatment for about 30min, the material was placed in a muffle furnace, heated to 500°C at a rate of 50°C / min, holding time for 2h; heated to 1000°C at a rate of 20°C / min, holding time 5h; at a rate of 10°C / min The temperature was raised to 1500 °C at a speed of min, and the holding time was 1 h; the calcined particles were cooled to 800 °C at a speed of 50 °C / min in a muffle furnace, and the holding time was 30 min; the temperat...

Embodiment 2

[0063] Embodiment 2: the preparation process of porous ore filter element material is as follows:

[0064] Preparation of raw materials: 700g of selenium ore, 160g of Muyu stone, 180g of lapis lazuli, 75g of magnesium ore, 190g of clay, and 48g of ammonium bicarbonate.

[0065] Preparation method: first grind the raw materials into powder in a mixer and pass through a 250-mesh sieve, then humidify and granulate in a granulator, the particle size of the granulated material is controlled at 8-12mm, and then transferred to a constant temperature drying oven at 60 °C for drying After treatment for about 25 minutes, the material was placed in a muffle furnace, heated to 800°C at a rate of 50°C / min, and held for 5h; heated to 1000°C at a rate of 20°C / min, held for 1h; at 10°C / min The temperature was raised to 1600 °C at a speed of min, and the holding time was 5 h. The calcined particles were cooled to 500 °C at a speed of 50 °C / min in a muffle furnace, and the holding time was 60 m...

Embodiment 3

[0070] Embodiment 3: the preparation process of porous ore filter element material is as follows:

[0071] Preparation of raw materials: 250g of medical stone, 700g of selenium ore, 100g of lapis lazuli, 150g of shells, 100g of magnesium ore, 190g of clay, and 48g of ammonium bicarbonate.

[0072] Preparation method: first grind the raw materials into powder in a mixer and pass through a 250-mesh sieve, then humidify and granulate in a granulator, the particle size of the granulated material is controlled at 8-12mm, and then transferred to a constant temperature drying oven at 60 °C for drying After treatment for about 25min, the material was placed in a muffle furnace, heated to 600°C at a rate of 50°C / min, holding time for 2h; heated to 1200°C at a rate of 20°C / min, holding time 3h; at 10°C / min The temperature was raised to 1600°C at a speed of min, and the holding time was 1h; the calcined particles were cooled to 700°C at a speed of 50°C / min in a muffle furnace, and the ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com