Rechargeable battery and application thereof

A technology for rechargeable batteries and positive electrodes of batteries, applied in the field of H01M4, which can solve the problems of inability to achieve fusion of conductive materials, low adhesion of electrode adhesives, and increased shrinkage difference, etc., to improve low thermal stability, increase curing speed, The effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

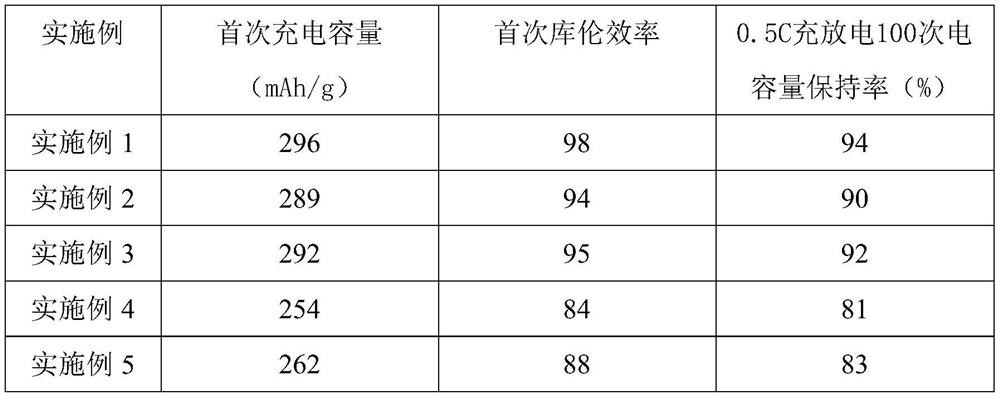

Examples

Embodiment 1

[0044] This example provides a rechargeable battery, the rechargeable battery includes a battery positive electrode, a battery negative electrode, an electrolyte and a separator.

[0045] The raw materials of the positive electrode of the battery include a positive electrode binder and a pole piece base.

[0046] The raw materials of the positive electrode binder include alkylamines, carboxyl compounds, modified substances, diglycidyl ethers, and active electrode components.

[0047] Alkylamine is a mixture of 1,2-propylenediamine and N-acetylethylenediamine, wherein the weight ratio of 1,2-propylenediamine and N-acetylethylenediamine is 1:0.5.

[0048] The carboxyl compound is a mixture of 2,3,3',4'-diphenyl ether tetracarboxylic dianhydride and bicyclo(2.2.2)oct-7-ene-2,3,5,6-tetracarboxylic dianhydride, wherein The weight ratio of 2,3,3',4'-diphenyl ether tetracarboxylic dianhydride and bicyclo(2.2.2)oct-7-ene-2,3,5,6-tetracarboxylic dianhydride is 1:3.2 .

[0049] The ...

Embodiment 2

[0059] This example provides a rechargeable battery, which is different from Example 1 in that in the positive electrode of the battery, the alkylamine is 1,2-propanediamine, which is a combination of 1,2-propanediamine and N-acetylethylenediamine. mixture, wherein the weight ratio of 1,2-propanediamine and N-acetylethylenediamine is 0.8:0.5.

[0060] The carboxyl compound is a mixture of 2,3,3',4'-diphenyl ether tetracarboxylic dianhydride and bicyclo(2.2.2)oct-7-ene-2,3,5,6-tetracarboxylic dianhydride, wherein The weight ratio of 2,3,3',4'-diphenyl ether tetracarboxylic dianhydride and bicyclo(2.2.2)oct-7-ene-2,3,5,6-tetracarboxylic dianhydride is 0.7:3.1 .

[0061] The raw materials of the negative electrode of the battery, in parts by weight, include 14 parts of graphite, 3 parts of carbon black and 0.7 part of a negative electrode binder.

[0062] In the electrolyte, the mixed ester solution includes ethylene carbonate (EC), dimethyl carbonate (DMC) and ethyl methyl car...

Embodiment 3

[0064] This example provides a rechargeable battery, which is different from Example 1 in that in the positive electrode of the battery, the alkylamine is 1,2-propanediamine, which is a combination of 1,2-propanediamine and N-acetylethylenediamine. mixture, wherein the weight ratio of 1,2-propanediamine and N-acetylethylenediamine is 1.1:0.75.

[0065] The carboxyl compound is a mixture of 2,3,3',4'-diphenyl ether tetracarboxylic dianhydride and bicyclo(2.2.2)oct-7-ene-2,3,5,6-tetracarboxylic dianhydride, wherein The weight ratio of 2,3,3',4'-diphenyl ether tetracarboxylic dianhydride and bicyclo(2.2.2)oct-7-ene-2,3,5,6-tetracarboxylic dianhydride is 1.2:3.2 .

[0066] The raw materials of the negative electrode of the battery, in parts by weight, include 19 parts of graphite, 4.5 parts of carbon black and 1.2 parts of a negative electrode binder.

[0067] In the electrolyte, the mixed ester solution includes ethylene carbonate (EC), dimethyl carbonate (DMC) and ethyl methyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com