Method for separating propyl guaiacol and propyl eugenol from lignin oil

A technology of propyl syringol potassium salt and guaiacol, which is applied in directions such as ether separation/purification, organic chemistry, ether preparation, etc., can solve the problems of high cost, lack of experimental data, time-consuming and reagent-consuming, etc. Simple method, low skill requirement, easy to enlarge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

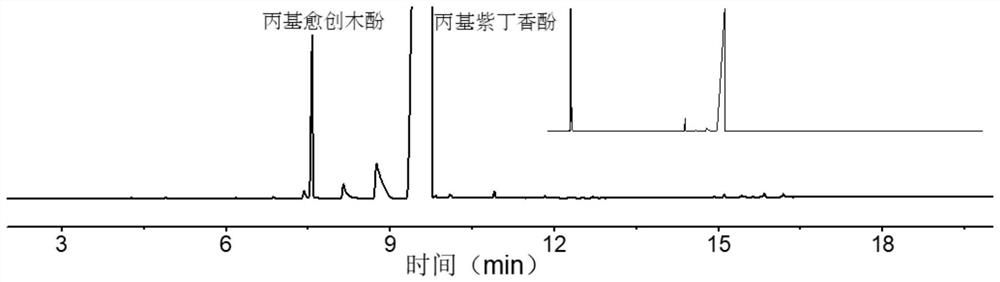

[0032] The method for separating propyl guaiacol and propyl eugenol from lignin oil comprises the following steps:

[0033] (1) Extract 10 g of lignin oil 4 times with 50 ml of n-hexane each time, and the extracts are combined to form the first extract. an extract;

[0034] (2) the oily substance obtained in step (1) is extracted three times with 20 ml of n-hexane each time, and combined to obtain the third extraction solution, which is refrigerated for 1 hour at -40°C to obtain the fourth extraction solution. extracting solution, combining the second extracting solution and the fourth extracting solution, and removing the solvent by rotary evaporation to obtain 2.5 g of concentrated monomer oil;

[0035] (3) dissolving the concentrated monomer oil obtained in step (2) in dichloromethane, and sequentially extracting with 15 ml of 0.2, 0.4, 0.6 and 0.8 mol / L potassium hydroxide aqueous solutions, and extracting 4 times in total, the lye after extraction Filter, combine, and c...

Embodiment 2

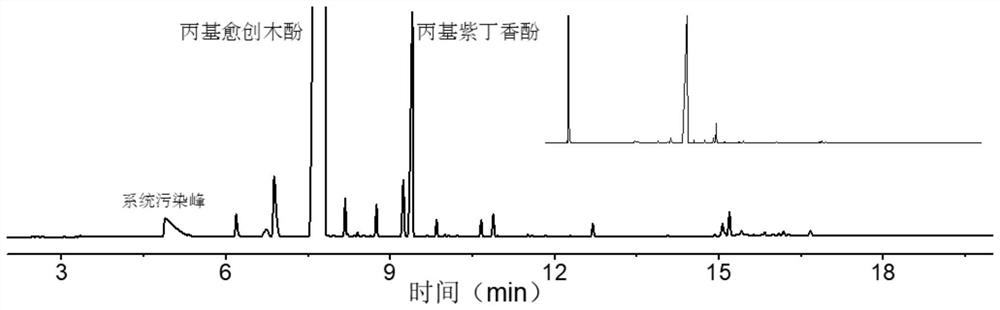

[0044] The method for separating propyl guaiacol and propyl eugenol from lignin oil comprises the following steps:

[0045] (1) Extract 10g of lignin oil 4 times with 50ml of hydrocarbon organic solvent each time (the hydrocarbon organic solvent can be composed of n-heptane and n-hexane in a ratio of 1:1 by volume), and the extracts are combined for the first extraction Refrigerate the first extraction solution at -20°C for 3 hours to separate out oil and the second extraction solution;

[0046] (2) the oily substance obtained in step (1) is extracted 3 times with 20ml of hydrocarbon organic solvent each time (the hydrocarbon organic solvent can be formed by n-heptane and n-hexane in a ratio of 1:1 by volume), and merged to obtain the first Three kinds of extraction solutions, the third extraction solution was refrigerated at -20 ℃ for 3 hours to obtain the fourth extraction solution, the second extraction solution and the fourth extraction solution were combined, and the solv...

Embodiment 3

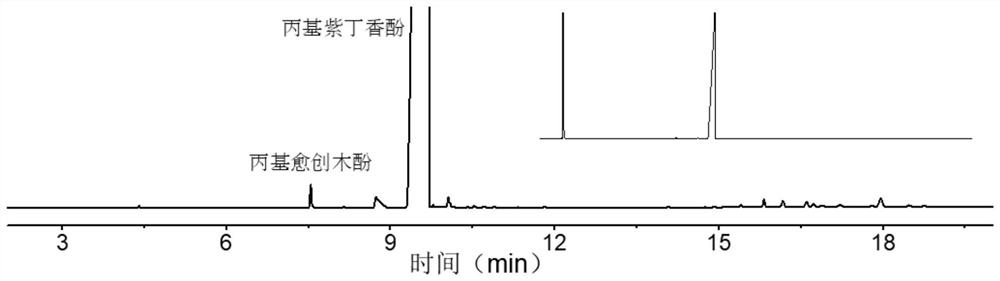

[0056] The method for separating propyl guaiacol and propyl eugenol from lignin oil comprises the following steps:

[0057] (1) Extract 10 g of lignin oil 4 times with 50 ml of 2,2-dimethylhexane (iso-octane) each time, and combine the extracts to form the first extract. The first extract was heated at 15°C Under refrigeration for 3 hours, the oil and the second extract are separated out;

[0058] (2) the oil obtained in step (1) is extracted 3 times with 20ml of 2,2-dimethylhexane (iso-octane) each time, and combined to obtain the third extraction solution, and the third extraction solution is Refrigerate at 15°C for 3 hours to obtain the fourth extract, combine the second extract and the fourth extract, and remove the solvent to obtain 2.4g of monomer concentrated oil;

[0059] (3) the monomer concentrated oil obtained in step (2) was dissolved in ethyl acetate, extracted with 35 ml of 0.5 and 0.7 mol / L potassium hydroxide aqueous solutions successively, extracted twice in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com