Preparation method and recovery method of recoverable PETG material

A recovery method and slurry technology, which is applied in the field of preparation of recyclable PETG materials, can solve the problems of insignificant effect and difficulty in maintaining the intrinsic viscosity of polyurethane, and achieve high recovery efficiency, excellent intrinsic viscosity, and the effect of maintaining intrinsic viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

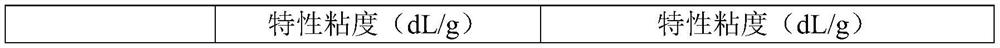

preparation Embodiment 1

[0050] 294g of biphenyltetracarboxylic dianhydride and 1860g of ethylene glycol were added to the reactor, and the reaction was carried out at 60°C for 24h.

[0051] Add 16268g of terephthalic acid and 10080g of 1,4 cyclohexanedimethanol into the reactor, under nitrogen atmosphere, add 0.5% antimony trioxide of the total mass at room temperature, slowly heat up, and react at 100°C 2h, the temperature was raised to 140°C for 1h reaction, the temperature was raised to 180°C for 1h reaction, the temperature was raised to 230°C and the reaction was incubated for 2h, and dehydration.

[0052] Under nitrogen protection, add 0.5% antimony acetate by total mass at room temperature, evacuate, and slowly heat up to 280°C until the on-line test torque reaches the set value.

preparation Embodiment 2

[0054] 441 g of biphenyltetracarboxylic dianhydride and 1860 g of ethylene glycol were added to the reactor, and the reaction was carried out at 60° C. for 24 h.

[0055] 16102g of terephthalic acid and 10080g of 1,4 cyclohexanedimethanol were added to the reactor, under nitrogen atmosphere, 0.5% antimony trioxide of the total mass was added at room temperature, the temperature was slowly raised, and the reaction was carried out at 100 ° C for 2h, The temperature was raised to 140 °C for reaction for 1 h, the temperature was raised to 180 °C for reaction for 1 h, the temperature was raised to 230 °C and the reaction was incubated for 2 h, and then dehydrated.

[0056] Under nitrogen protection, add 0.5% antimony acetate by total mass at room temperature, evacuate, and slowly heat up to 280°C until the on-line test torque reaches the set value.

preparation Embodiment 3

[0058] 588g of biphenyltetracarboxylic dianhydride and 1860g of ethylene glycol were added to the reactor, and the reaction was carried out at 60°C for 24h.

[0059] Add 15936g of terephthalic acid and 10080g of 1,4 cyclohexanedimethanol into the reactor, under nitrogen atmosphere, add 0.5% antimony trioxide of the total mass at room temperature, slowly heat up, and react at 100°C 2h, the temperature was raised to 140°C for 1h reaction, the temperature was raised to 180°C for 1h reaction, the temperature was raised to 230°C and the reaction was incubated for 2h, and dehydration.

[0060] Under nitrogen protection, add 0.5% antimony acetate by total mass at room temperature, evacuate, and heat up to 280° C. until the on-line test torque reaches the set value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com