Layer-by-layer self-assembled calcium oxide microcapsule as well as preparation method and application thereof

A layer-by-layer self-assembly, calcium oxide technology, applied in microcapsule preparations, microsphere preparation, chemical instruments and methods, etc., can solve the problems of high reaction speed and heat release speed, difficult to control heat release, and low utilization efficiency, etc. Achieve the effect of preventing reservoir damage, low cost and protecting reservoir

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A method for preparing layer-by-layer self-loading calcium oxide microcapsules, comprising the following steps:

[0052] (a) Preparation of polyaldehyde sodium alginate

[0053] i. Disperse 10 g of sodium alginate in 50 mL of absolute ethanol to prepare suspension I.

[0054] ii. Dissolve 5.404 g of sodium periodate in 50 mL of pure water to prepare solution II.

[0055] iii. Add Solution II to Suspension I, and magnetically stir at room temperature in the dark for 6 hours, then add 3.5 mL of ethylene glycol to terminate the reaction.

[0056] iv. Add 100 mL of the reactant into 500 mL of absolute ethanol to separate out a precipitate, filter with suction, and vacuum dry at 40° C. to obtain sodium polyaldehyde alginate.

[0057] (b) Preparation of modified calcium oxide cores

[0058] i. Uniformly mix 1 mL of 3-aminopropyltrimethoxysilane and 100 mL of absolute ethanol at 25° C. to obtain a silane coupling agent solution.

[0059] ii. Mix 10 g of calcium oxide with ...

Embodiment 2

[0068] A method for preparing layer-by-layer self-loading calcium oxide microcapsules, comprising the following steps:

[0069] (a) Preparation of polyaldehyde sodium alginate

[0070] i. Disperse 10 g of sodium alginate in 50 mL of absolute ethanol to prepare suspension I.

[0071] ii. Dissolve 5.404 g of sodium periodate in 50 mL of pure water to prepare solution II.

[0072] iii. Add Solution II to Suspension I, and magnetically stir at room temperature in the dark for 6 hours, then add 3.5 mL of ethylene glycol to terminate the reaction.

[0073] iv. Add 100 mL of the reactant into 500 mL of absolute ethanol to separate out a precipitate, filter with suction, and vacuum dry at 40° C. to obtain sodium polyaldehyde alginate.

[0074] (b) Preparation of modified calcium oxide cores

[0075] i. Uniformly mix 1 mL of 3-aminopropyltrimethoxysilane and 100 mL of absolute ethanol at 25° C. to obtain a silane coupling agent solution.

[0076] ii. Evenly mix 20 g of calcium oxid...

Embodiment 3

[0085] A method for preparing layer-by-layer self-loading calcium oxide microcapsules, comprising the following steps:

[0086] (a) Preparation of polyaldehyde sodium alginate

[0087] i. Disperse 10 g of sodium alginate in 50 mL of absolute ethanol to prepare suspension I.

[0088] ii. Dissolve 5.404 g of sodium periodate in 50 mL of pure water to prepare solution II.

[0089] iii. Add Solution II to Suspension I, and magnetically stir at room temperature in the dark for 6 hours, then add 3.5 mL of ethylene glycol to terminate the reaction.

[0090] iv. Add 100 mL of the reactant into 500 mL of absolute ethanol to separate out a precipitate, filter with suction, and vacuum dry at 40° C. to obtain sodium polyaldehyde alginate.

[0091] (b) Preparation of modified calcium oxide cores

[0092] i. Uniformly mix 1 mL of 3-aminopropyltrimethoxysilane and 100 mL of absolute ethanol at 25° C. to obtain a silane coupling agent solution.

[0093]ii. Mix 40 g of calcium oxide with t...

PUM

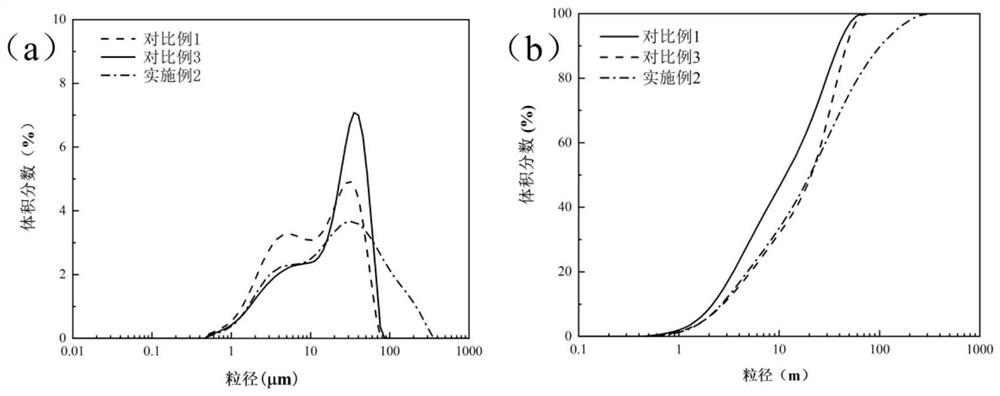

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com