Method for monitoring concentration of sodium 3, 3 '-dithiodipropane sulfonate in copper foil plating solution

A plating solution and concentration technology, used in the measurement of color/spectral properties, material analysis by observing the effect on chemical indicators, and analysis by causing chemical reactions to occur in materials, etc. The interference effect of other additives, etc., to ensure reliability and accuracy, improve controllability and stability, and improve the effect of SPS concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In the copper foil electrolysis process, in a certain period of time, the monitoring method of the present invention is used to monitor the SPS concentration in real time, and the details are as follows:

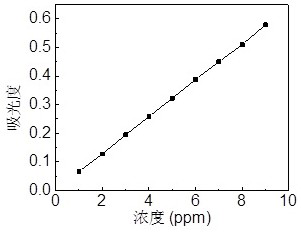

[0039] (1) Use acetonitrile to dissolve SPS, and configure 5 to 9 SPS standard solutions with calibration concentrations in the concentration range of 0.5~50 ppm. In this example, 9 SPS standard solutions with calibration concentrations are configured, and the calibration concentrations are: 1, 2, 3, 4, 5, 6, 7, 8, 9 ppm. Then mix the standard solution with H 2 PO 4 - -HPO 4 2- The buffer solution and the chromogenic reagent are mixed and reacted to develop color, and then the absorbance test is carried out, and the standard curve of SPS concentration and absorbance is drawn. The developer used in this example is sodium borohydride. 1, 2, 3, 4, 5, 6, 7, 8, and 9 ppm of the SPS standard solution of each calibration concentration of the measured absorbance: 0.066,...

Embodiment 2

[0046] The electrolysis process of another copper foil adopts the following steps to monitor the SPS concentration:

[0047] The chromogenic agent used in steps (1) and (2) is TCEP, and the remaining steps are the same as in Example 1, and the monitoring data of specific steps will not be listed one by one.

[0048] Finally, the monitoring results of the whole electrolytic process of the copper foil in this example show that the SPS concentration is stable in the range of 3.1-3.5 ppm during the production process of the whole copper foil, and the gloss, tensile strength, roughness, etc. The key indicators remained stable, and the fluctuation range was less than 5%, indicating that the above technical methods can indeed achieve effective monitoring and regulation of SPS concentration and ensure the quality stability of copper foil products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com