Dimethyldichlorosilane hydrolysis process with desorption function

A dimethyldichlorosilane and functional technology, applied in the direction of silicon organic compounds, can solve the problems of difficult control of the hydrolysis process and low recovery efficiency of hydrogen chloride, and achieve the effects of easy separation, controllable sticking and improved recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

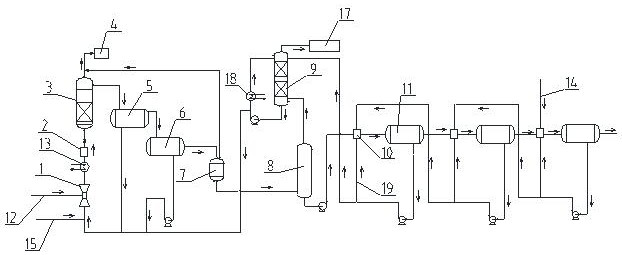

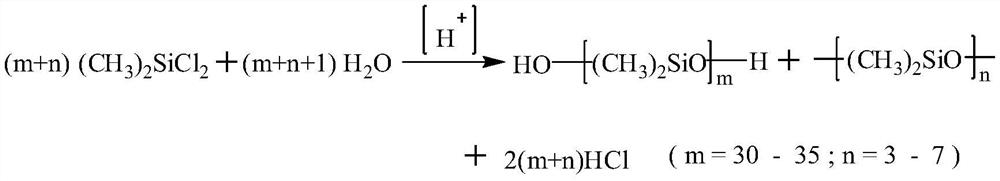

Embodiment 1

[0016]The dimethyldichlorosilane hydrolysis process with desorption function described in this embodiment 1 includes hydrolysis reaction, degassing treatment and multi-stage water washing reaction steps, and dimethyldichlorosilane monomer and hydrochloric acid are first passed through the hydrolysis system. After mixing in the hydrolysis mixer, analytical separation of hydrogen chloride gas in the analytical tower 3, and dilute hydrochloric acid in the oil-water separator, the dimethyldichlorosilane hydrolyzate separates the hydrogen chloride gas again in the degassing system, and the hydrogen chloride gas separated by the degassing system enters the absorption The tower 9 is washed and absorbed, and the dimethyldichlorosilane hydrolyzate enters the multi-stage water washing system again to carry out multi-stage water eluting chlorine. The last stage water washing system of the multi-stage water washing reaction step is provided with a desalted water inlet 14. The desalinated w...

Embodiment 2

[0023] The dimethyldichlorosilane hydrolysis process with desorption function described in this embodiment 2 includes the steps of hydrolysis reaction, degassing treatment and multi-stage water washing reaction. The dimethyldichlorosilane monomer and hydrochloric acid are first passed through the hydrolysis system. After mixing in the hydrolysis mixer, analytical separation of hydrogen chloride gas in the analytical tower 3, and dilute hydrochloric acid in the oil-water separator, the dimethyldichlorosilane hydrolyzate separates the hydrogen chloride gas again in the degassing system, and the hydrogen chloride gas separated by the degassing system enters the absorption The tower 9 is washed and absorbed, and the dimethyldichlorosilane hydrolyzate enters the multi-stage water washing system again to carry out multi-stage water eluting chlorine. The last stage water washing system of the multi-stage water washing reaction step is provided with a desalted water inlet 14. The desal...

Embodiment 3

[0030] The dimethyldichlorosilane hydrolysis process with desorption function described in this embodiment 3 includes the steps of hydrolysis reaction, degassing treatment and multi-stage water washing reaction. The dimethyldichlorosilane monomer and hydrochloric acid are first passed through the hydrolysis system. After mixing in the hydrolysis mixer, analytical separation of the hydrogen chloride gas in the analytical tower 3, and dilute hydrochloric acid in the oil-water separator, the dimethyldichlorosilane hydrolyzate separates the hydrogen chloride gas again in the degassing system, and the hydrogen chloride gas separated by the degassing system enters the absorption The tower 9 is washed and absorbed, and the dimethyldichlorosilane hydrolyzate enters the multi-stage water washing system again to carry out multi-stage water eluting chlorine. The last stage water washing system of the multi-stage water washing reaction step is provided with a desalted water inlet 14. The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com