Method and reaction device for synthesizing oligomeric alkyl phosphate by one-pot method

An oligomeric alkyl phosphate ester and a technology for a reaction device, which are applied in chemical instruments and methods, chemical/physical/physical-chemical stationary reactors, chemical/physical/physical-chemical nozzle reactors, etc., can solve the problem of high production costs. , long production cycle, low reaction efficiency and other problems, to achieve the effect of improving device production capacity, high volume utilization rate, and improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

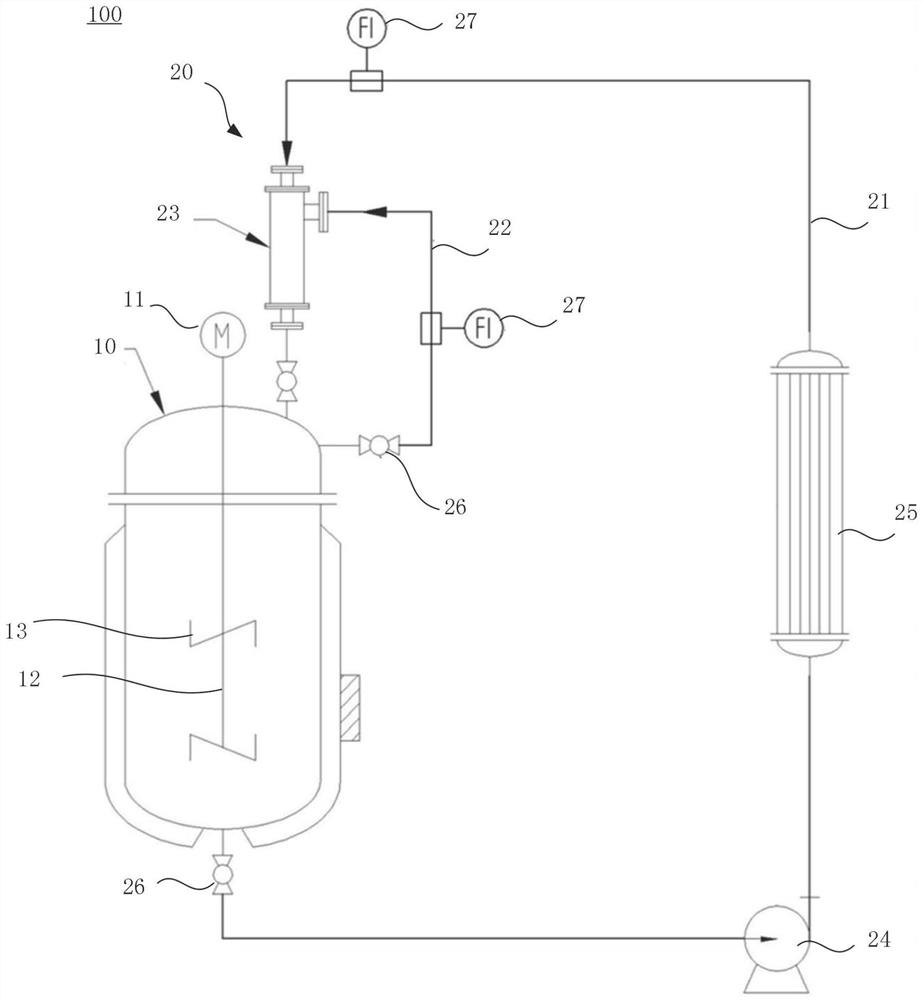

[0077] Adopt single-tank reactor, add phosphorus pentoxide automatic feeding purging unit and circulating flow jet reaction system, namely reaction device 100, and then adopt the following steps to carry out production operation:

[0078] (1) The triethyl phosphate of 6kg is added to the stirring reactor, that is, the container body 10, in, and then the phosphorus pentoxide of 3kg is slowly added. The material filling factor is controlled to be 0.7. During the addition, vigorous stirring was performed to prevent agglomeration, maintained for 1 hour, and the temperature was controlled at about 60°C to complete the first-step reaction.

[0079] (2) 25g of titanium oxide acetylacetone was added to the reaction system, and then slowly 3.24kg of ethylene oxide was introduced into the stirring reactor to react. After starting to feed ethylene oxide, control the temperature of the reaction system to gradually increase with the increase of the ethylene oxide feeding amount, and the r...

example 2

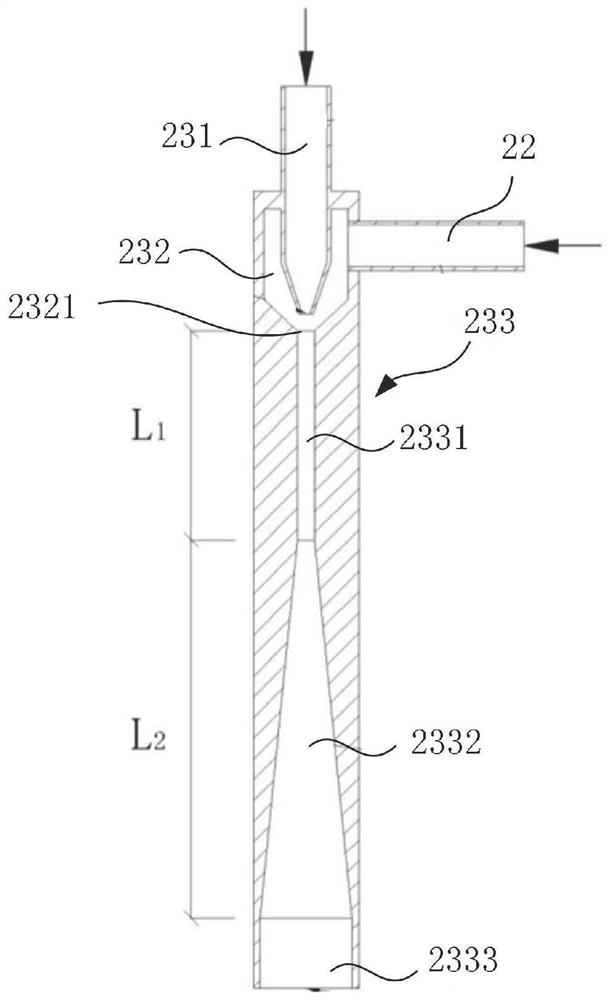

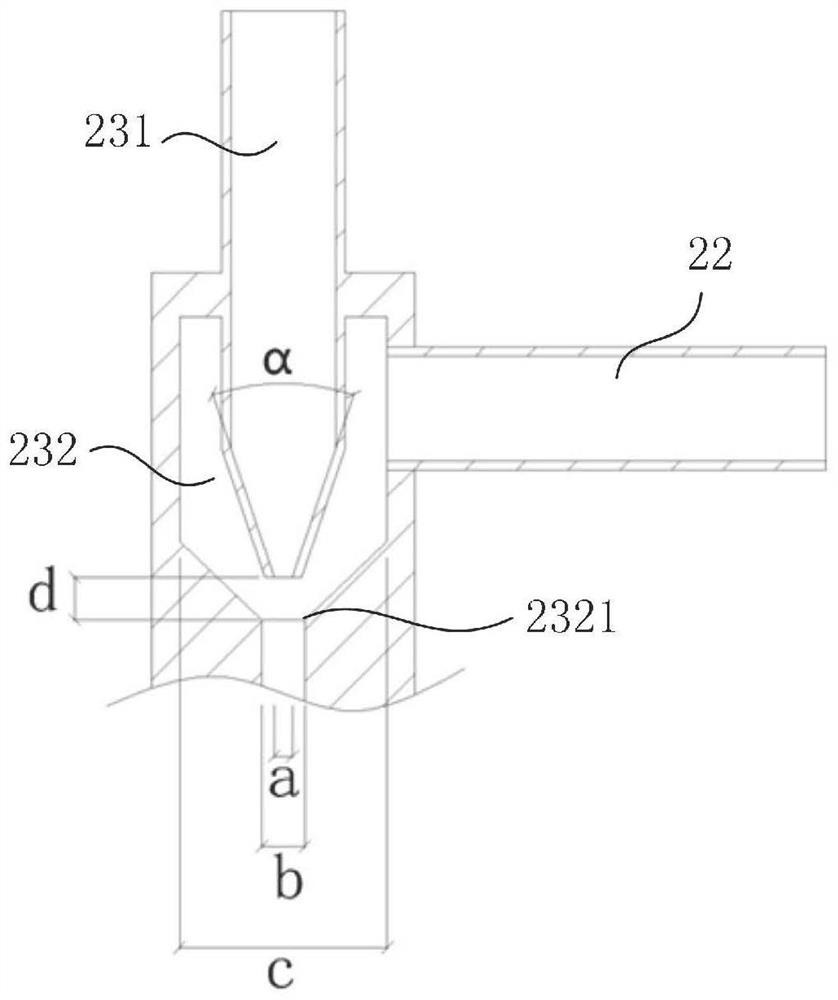

[0082]Using the optimized new high-efficiency reaction process and reaction device 100 of the oligomeric alkyl phosphate flame retardant, 4.5 kg of triethyl phosphate was added to the container body 10, and then 2.5 kg of phosphorus pentoxide was slowly added. During the addition process, vigorous stirring was performed to prevent agglomeration, maintained for 3 hours, and the temperature was controlled at about 60°C to generate the intermediate pyrophosphate. 20 g of α-stannous was added to the reaction system, and then a total amount of 2.4 kg of ethylene oxide was slowly introduced into the container body 10 to conduct the reaction. After starting to feed ethylene oxide, the temperature of the reaction system was controlled, the reaction temperature was maintained at 100°C, the ratio of the air flow rate to the liquid flow rate of the jet reactor 23 was 1:3, and after 42 hours, the acid value of the product was less than 1.5mg .KOH / g, stop the reaction, remove the residual ...

example 3

[0084] Using the optimized new high-efficiency reaction process and reaction device 100 of oligomeric alkyl phosphate flame retardant, 7.5 kg of trimethyl phosphate was added to the container body 10, and then 3.6 kg of phosphorus pentoxide was slowly added. During the addition, vigorous stirring was performed to prevent agglomeration, maintained for 4 hours, and the temperature was controlled at about 85°C to generate an intermediate pyrophosphate. 38 g of stannous octoate was added to the reaction system, and then 3.9 kg of ethylene oxide in total was slowly introduced into the container body 10 to carry out the reaction. After starting to feed ethylene oxide, the temperature of the reaction system was controlled, the reaction temperature was maintained at 135°C, the ratio of the air flow rate to the liquid flow rate of the jet reactor 23 was 1:4, and the acid value of the product was less than 1.5 after 36 hours of reaction. mg.KOH / g, stop the reaction to obtain the oligome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com