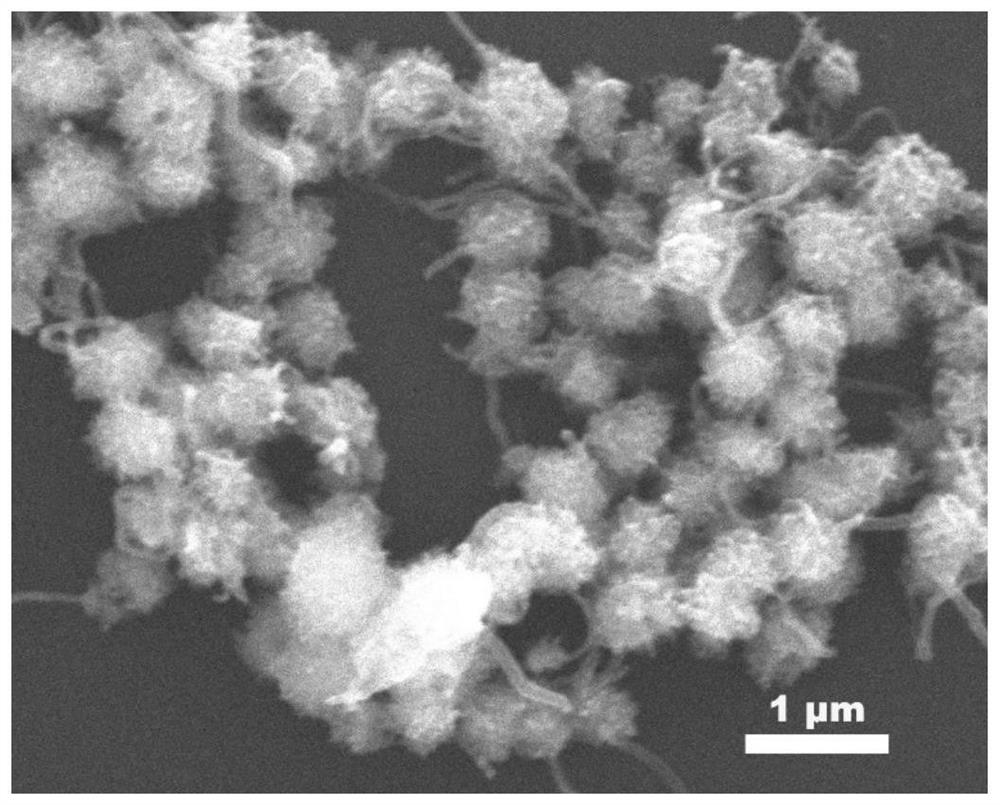

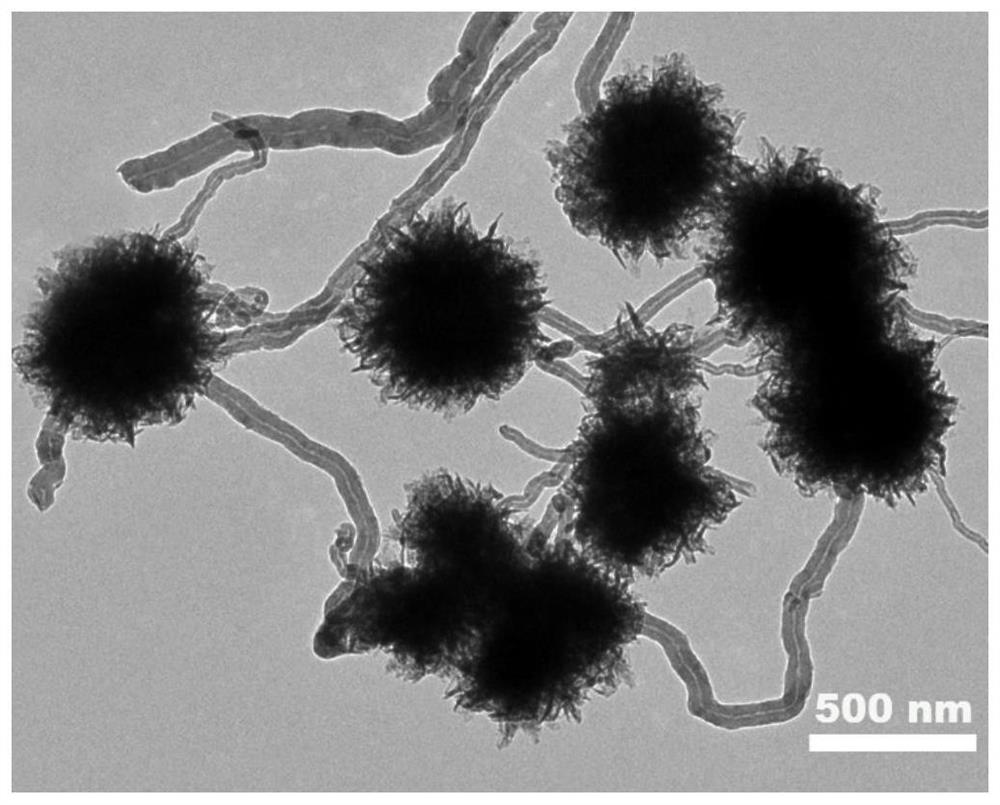

Calabash string-shaped CuO/CNT composite catalyst and preparation method thereof

A composite catalyst, gourd technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve complex preparation, prone to agglomeration or deformation, synthesis cycle To solve the problems of long time, to achieve the effect of simple preparation method, promote electron transfer, and increase conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation method of the cucurbit string CuO / CNT composite catalyst of the present invention specifically comprises the following steps:

[0026] (1) Take 0.5g of CNT and place it in 60mL of a mixed solution of concentrated nitric acid and concentrated sulfuric acid (1:3, v / v), heat at 120°C for 3 hours, and filter the resulting solution with a cellulose membrane filter (pore size 0.25 μm) filter, wash until the pH of the eluate is 6-7, then centrifuge and dry to obtain activated CNT powder, and the obtained powder is dispersed in 1 mL of deionized water; in the CNT dispersion, the mass fraction of CNTs is 50%;

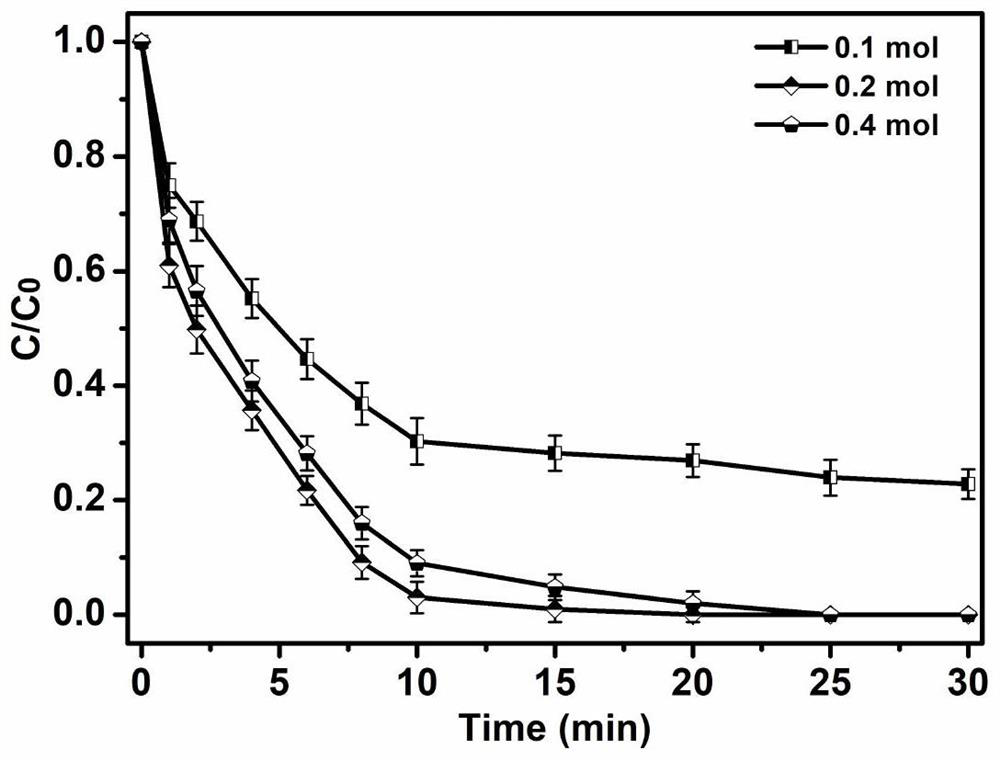

[0027] (2) Dissolve 0.2 mol of cuprous chloride in an aqueous solution of 10 mL of ethanol to obtain solution A; dissolve 0.05 g of surfactant P123 in 5 mL of ethanol to obtain solution B; at room temperature, the ratio by volume is 1:2 Mix solution A and solution B to obtain a mixed solution;

[0028] (3) Add 0.45 mL of ammonia water (25% to 28% by mass)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com