Wastewater treatment device for sweet potato processing and cleaning

A technology of wastewater treatment and potato, applied in the field of potato processing, can solve the problems of water environment hazard, poor treatment effect, inability to effectively reduce COD value, ammonia nitrogen value and total phosphorus value of potato wastewater, so as to reduce COD value and reduce equipment cost. and operating costs, avoiding the effect of rapid output in a short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

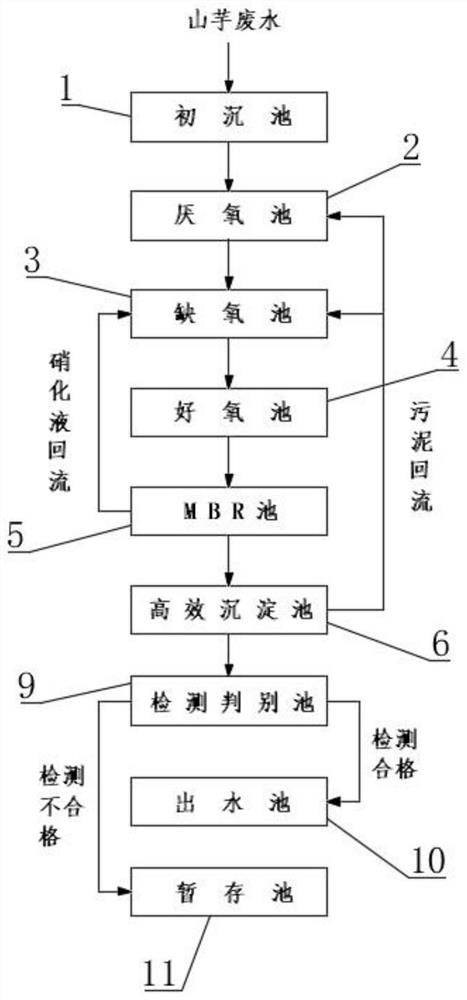

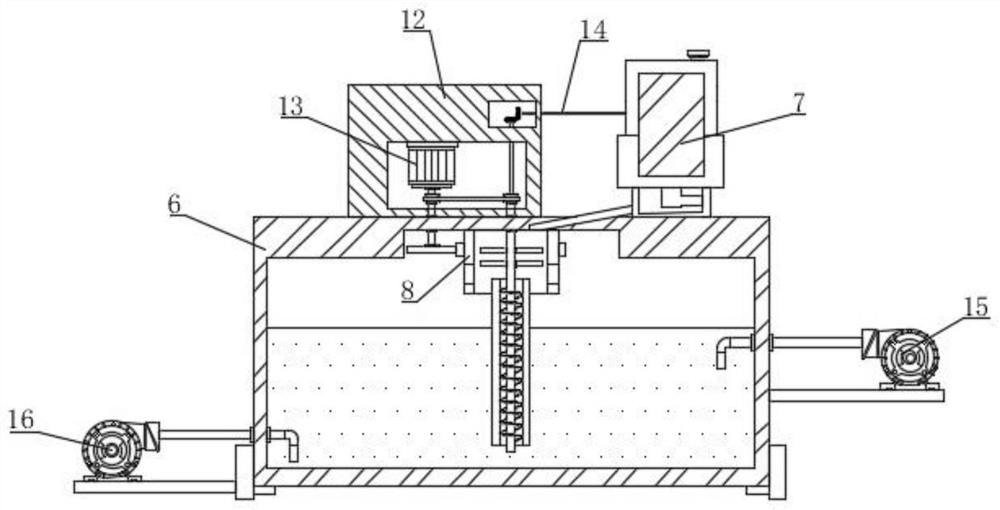

[0044] like Figure 1-6 As shown, the present invention proposes a waste water treatment device for processing and cleaning potato, including a primary sedimentation tank 1, an anaerobic tank 2, an anoxic tank 3, an aerobic tank 4, an MBR tank 5 and a high-efficiency sedimentation tank 6. The waste water enters the primary sedimentation tank 1, and the supernatant in the primary sedimentation tank 1 enters the anaerobic tank 2, the anoxic tank 3, the aerobic tank 4, the MBR tank 5 and the high-efficiency sedimentation tank 6 in turn. The PH in the anaerobic tank 2 The pH value is 6.8-7.2, the pH value in the anoxic tank 3 is 6.5-7.5, the pH value in the aerobic tank 4 is 7.5-8.5, and the anaerobic tank 2 coexists with acid-producing bacteria and methanogenic bacteria; The dissolved oxygen in pool 2 is less than 0.2 mg / L, the dissolved oxygen in anoxic pool 3 is less than 0.5 mg / L, and the dissolved oxygen in aerobic pool 4 is 2-4 mg / L; The nitrifying liquid return pipe commun...

Embodiment 2

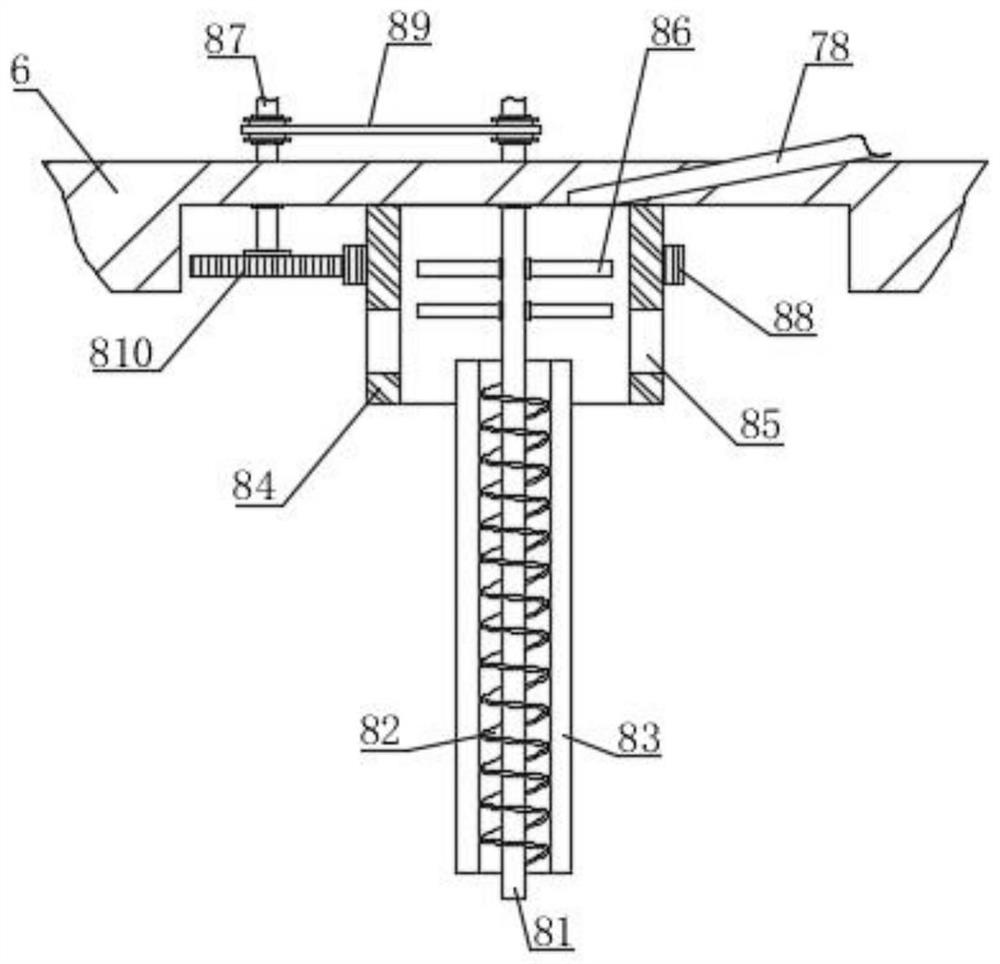

[0059] like Image 6 and Figure 9-10 As shown, the difference between this embodiment and Embodiment 1 is that the top end of the lifting and stirring shaft 81 extends into the installation and fixing box 12, and the installation and fixing box 12 is mounted with a rotating intermediate shaft 14 through a bearing, and the rotating intermediate shaft 14 is away from the installation and fixed. One end of the box 12 extends into the self-adjusting medicine box 7, and the top of the lifting and stirring shaft 81 is connected with the rotating shaft 14 through a bevel gear. The self-adjusting medicine box 7 is provided with a medicine storage room 71 and a material receiving room 74, and The medicine storage chamber 71 is located above the receiving chamber 74. The medicine storage chamber 71 and the receiving chamber 74 communicate with each other through the communication port 75. The medicine storage chamber 71 is rotatably installed with a rotating fragment shaft 76 through a...

Embodiment 3

[0062] like Figure 6-8 As shown, the difference between this embodiment and Embodiment 1 and Embodiment 2 is that a feeding port 72 is installed on the top of the self-regulating medicine box 7, and flocculant or precipitant can be added to the box through the feeding port 72, and the feeding chamber 74 A concave inclined seat 73 is installed inside, the bottom of the concave inclined seat 73 is a vertical section, the vertical section extends downward into the lower material box 77, and the vertical section is provided with a lower material channel 79 and a storage groove 713, The opening and closing cylinder 714 is fixedly installed in the receiving groove 713, and the opening and closing block 712 is installed on the extending end of the opening and closing cylinder 714. When the opening and closing block 712 is closed, the opening and closing block 712 blocks the entry of the unloading channel 79 into the unloading channel 79 to block it. in a smooth state;

[0063] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com