Process for removing propylene oxide in PPC (polypropylene carbonate) production process

A technology for the production process of propylene oxide, which is applied in the field of propylene oxide removal technology, can solve the problems of low average residence time of materials, limited equipment processing capacity, cumbersome separation and purification process, etc., and achieves low equipment cost and site requirements, Single equipment has high processing capacity and the effect of solving technical bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below, so that those skilled in the art can implement it with reference to the description and accompanying drawings.

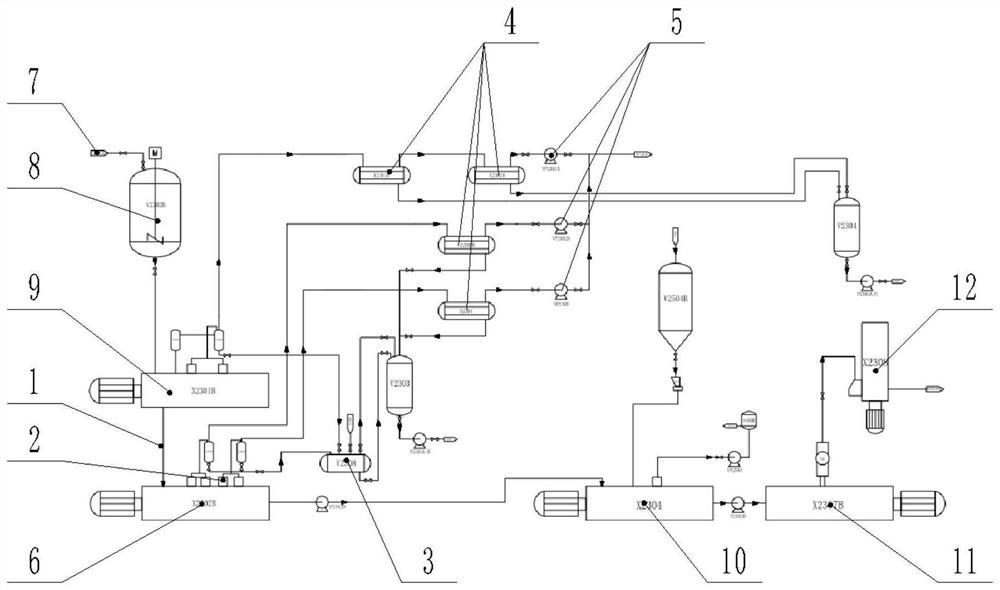

[0021] A process for removing propylene oxide in the PPC production process includes the following:

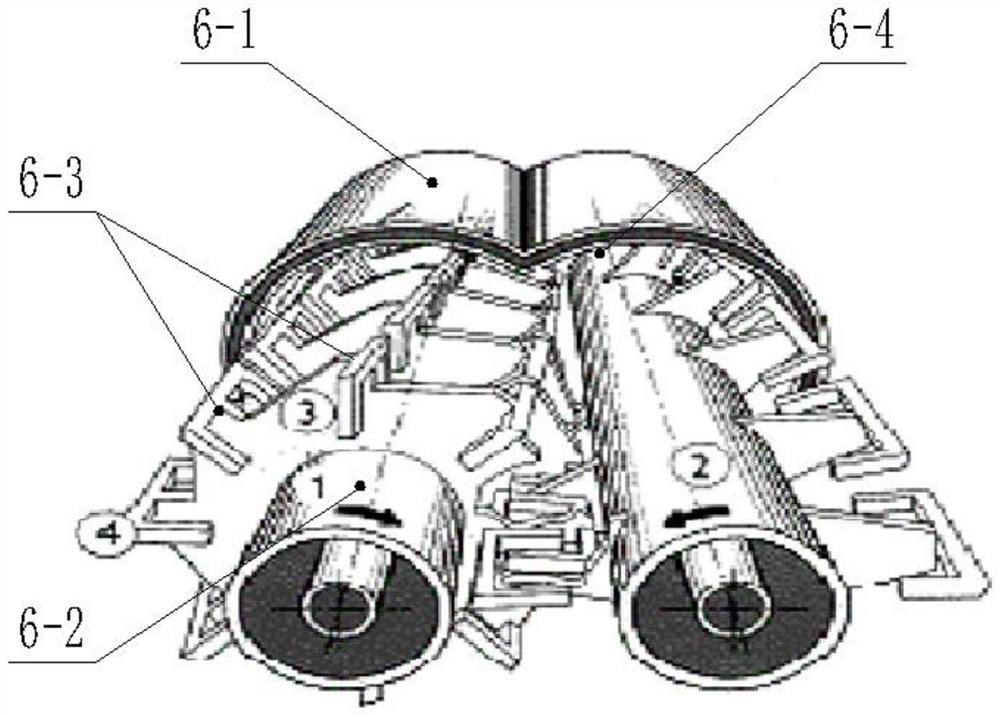

[0022] The SCP unit composed of SCP horizontal self-cleaning reactors with a cavity volume of 2000L is customized according to the actual production data. The SCP horizontal self-cleaning reactors are often used for the reaction and polymerization of high polymers (or related to high-viscosity material systems). , large-capacity devolatilization, heat and mass transfer, mixing and kneading, evaporation and concentration, phase change crystallization and other processes, with the advantages of short process, continuous, high efficiency, etc., are widely used in the rubber product industry, the internal structure is as follows figure 2 Display: including the equipment shell 6-1, the main shaft 6-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com