Polyethylene foam material and preparation method thereof

A technology of polyethylene foaming and grafting polyethylene, applied in the field of materials, can solve the problems of poor heat resistance, poor mechanical strength, poor flame retardant effect, etc., and achieve the effects of improving mechanical strength, strength and flame retardant performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

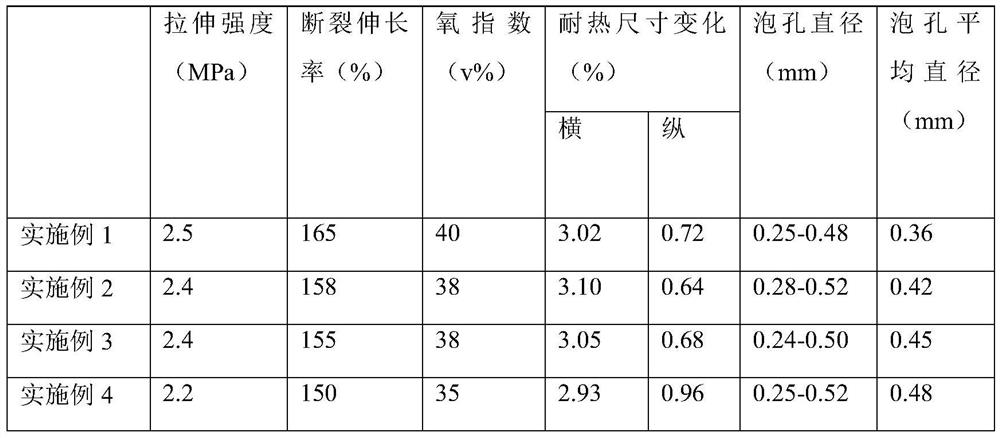

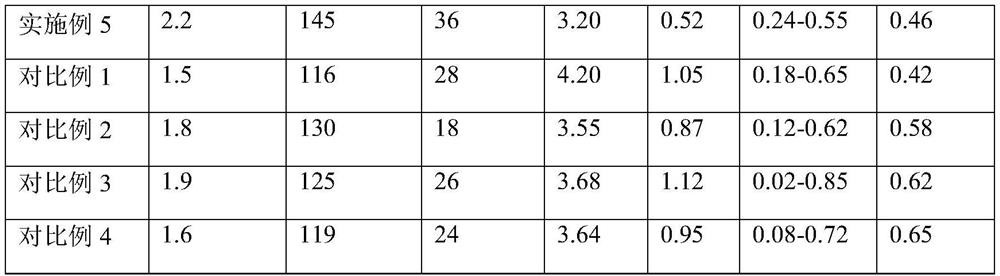

Examples

preparation example Construction

[0037] And, the preparation method of above-mentioned polyethylene foam material comprises the following steps:

[0038] Step a, weigh described low density polyethylene, mica powder and maleic anhydride grafted polyethylene by weight and mix to obtain the first mixture;

[0039] Step b, weighing the chitosan, the polyaziridine crosslinking agent and the flame retardant in parts by weight and mixing at 10-20° C. to obtain a second mixture;

[0040] Step c, add foaming agent (when the component contains stearic acid, stearic acid and foaming agent are added in the first mixture) to the first mixture and mix, then add the second mixture The materials are mixed, thinly smelted into sheets, molded and foamed to obtain the polyethylene foamed material.

[0041] Step c also includes adding the stearic acid when adding the blowing agent to the first mix.

[0042]The present invention can improve the mechanical strength of the foamed material on the one hand and the heat resistance ...

Embodiment 1

[0047] A polyethylene foam material, comprising the following components in parts by weight: 18 parts of low-density polyethylene, 1 part of mica powder, 1.5 parts of maleic anhydride grafted polyethylene, 6.5 parts of chitosan, 2 parts of joint agent, 2 parts of flame retardant, 3 parts of foaming agent and 1.2 parts of stearic acid;

[0048] Wherein, the flame retardant is a mixture of sodium carboxymethyl cellulose and sodium alginate, and the weight ratio of sodium carboxymethyl cellulose and sodium alginate is 2:1; the foaming agent includes AC foaming agent and foaming agent H , the weight ratio of foaming agent AC foaming agent and foaming agent H is 1.4:1.

[0049] Its preparation method comprises the following steps:

[0050] Step a, taking by weight low density polyethylene, mica powder and maleic anhydride grafted polyethylene and mixing to obtain the first mixture;

[0051] Step b: Weighing chitosan, polyaziridine cross-linking agent and flame retardant in parts ...

Embodiment 2

[0054] A polyethylene foam material, comprising the following components in parts by weight: 15 parts of low-density polyethylene, 0.8 parts of mica powder, 1.2 parts of maleic anhydride grafted polyethylene, 6 parts of chitosan, 1.5 parts of joint agent, 1.5 parts of flame retardant, 2.5 parts of foaming agent and 1 part of stearic acid;

[0055] Wherein, the flame retardant is a mixture of sodium carboxymethyl cellulose and sodium alginate, and the weight ratio of sodium carboxymethyl cellulose and sodium alginate is 2:1; the foaming agent includes AC foaming agent and foaming agent H , the weight ratio of foaming agent AC foaming agent and foaming agent H is 1.2:1.

[0056] Its preparation method comprises the following steps:

[0057] Step a, taking by weight low density polyethylene, mica powder and maleic anhydride grafted polyethylene and mixing to obtain the first mixture;

[0058] Step b. Weigh chitosan, polyaziridine cross-linking agent and flame retardant in parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com