Modified sealing agent, anti-corrosion coating and method for preparing anti-corrosion coating

A sealing agent and anti-corrosion technology, applied in anti-corrosion coatings, coatings, devices for coating liquid on the surface, etc., can solve the problems of discounted long-lasting corrosion resistance, poor corrosion resistance of pots, and decreased corrosion resistance , to achieve the effect of lasting anti-corrosion and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] A method of preparing an anti-corrosion coating according to an exemplary embodiment of the inventive concept includes: providing a substrate; applying a corrosion-resistant powder on the surface of the substrate to form a transition layer; and applying a modified sealer on the surface of the transition layer to form a seal Floor.

[0043] According to an exemplary embodiment of the present inventive concept, the substrate may be a substrate known in the art that needs to be treated with anti-corrosion. For example, in accordance with the present inventive concept, the substrate may comprise a cast iron cookware blank. However, the present inventive concept is not limited thereto, and those skilled in the art may select an appropriate substrate according to the present inventive concept.

[0044] According to an exemplary embodiment of the present inventive concept, in order to facilitate subsequent processes and product quality, the step of providing the substrate may...

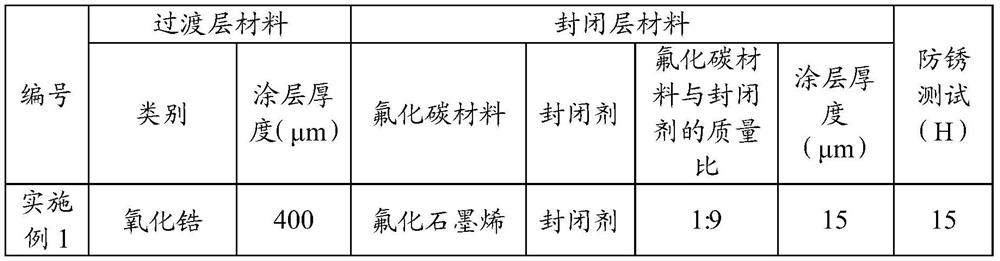

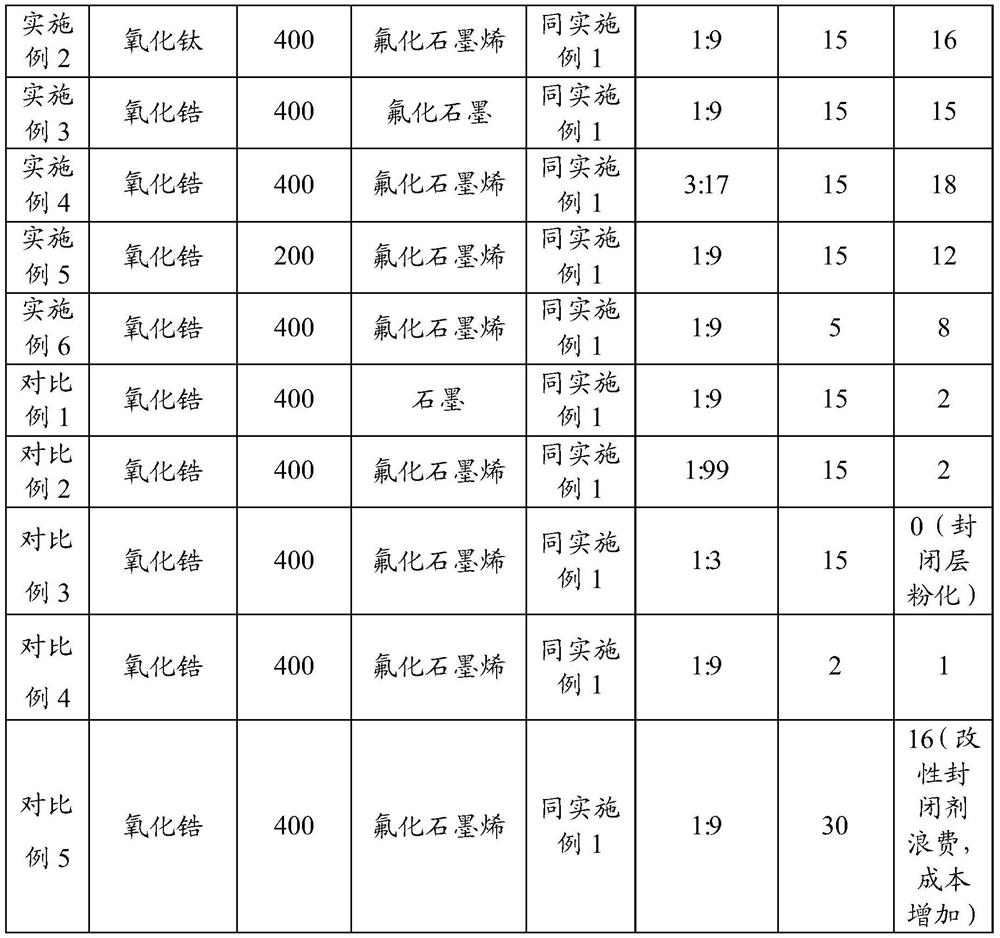

Embodiment 1

[0060] Prepare the cast iron pot embryo, use a cleaning solution to clean the surface of the pot embryo, and then dry it, wherein the cleaning solution includes 5% fatty alcohol polyoxyethylene ether, 9% coconut oil alkanolamide, 3% Triethanolamine oleate, 9% monoethanolamine, 2% benzotriazole and 72% water; and then roughened the surface of the pot embryo by sandblasting, so that the surface roughness of the pot embryo was 1.5 μm.

[0061]A zirconia powder having a particle size of 50 μm was prepared, and the zirconia powder was subjected to low-pressure plasma spraying. The low-pressure plasma spraying process includes: preheating the cooker to 150°C; pumping the vacuum of the spraying chamber to 3Pa, and then rushing into argon to 6×10 3 Pa; plasma arcing, adjust the transfer arc power to 30Kw, adjust the arc current to 600A, set a spraying distance of 120mm and a spraying angle of 60°, and then spray the pot embryo, wherein the powder feeding speed is 25g / min , the hydrog...

Embodiment 2

[0067] The difference from Example 1 is that the transition layer is formed by spraying with titanium oxide powder instead of zirconium oxide powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com