Method for preparing 6N-grade terbium chloride through extraction and separation

A terbium chloride and extraction technology is applied in the field of preparing 6N-level terbium chloride aqueous solution to achieve the effects of less reagent consumption, high purity and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The unsupported organic phase is sulfonated kerosene with P229, wherein the concentration of P229 is 1.0 mol / L.

[0022] The concentrations of rare earth elements in 4N-grade terbium chloride aqueous solution are Sm 0.45 mg / L, Eu 1.3 mg / L, Gd 4.7 mg / L, Tb 160 g / L, Dy 6.5 mg / L, and Ho 1.6 mg / L, respectively.

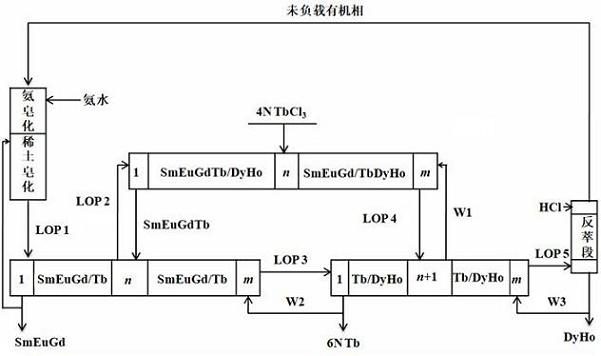

[0023] SmEuGdTb / TbDyHo full-load fractionation extraction system: the equilibrium organic phase of the feed stage of the SmEuGd / Tb full-load fractionation extraction system is the rare earth saponified organic phase, and the rare earth saponified organic phase enters the SmEuGdTb / TbDyHo full-load fractionation extraction system from the first stage; The terbium chloride aqueous solution is the feed liquid, and the feed liquid 4N-grade terbium chloride aqueous solution enters the SmEuGdTb / TbDyHo full-load fractionation extraction system from the 13th stage (feed stage); the equilibrium water phase of the feed stage of the Tb / DyHo full-load fractionation extraction sy...

Embodiment 2

[0030] The unsupported organic phase is sulfonated kerosene with P229, wherein the concentration of P229 is 1.0 mol / L.

[0031] The concentrations of rare earth elements in 4N-grade terbium chloride aqueous solution are Sm 0.24 mg / L, Eu 0.79 mg / L, Gd 3.1 mg / L, Tb 158 g / L, Dy 3.6 mg / L, and Ho 0.85 mg / L, respectively.

[0032] SmEuGdTb / TbDyHo full-load fractionation extraction system: the equilibrium organic phase of the feed stage of the SmEuGd / Tb full-load fractionation extraction system is the rare earth saponified organic phase, and the rare earth saponified organic phase enters the SmEuGdTb / TbDyHo full-load fractionation extraction system from the first stage; The terbium chloride aqueous solution is the feed liquid, and the feed liquid 4N-grade terbium chloride aqueous solution enters the SmEuGdTb / TbDyHo full-load fractionation extraction system from the 13th stage (feed stage); the equilibrium water phase of the feed stage of the Tb / DyHo full-load fractionation extraction ...

Embodiment 3

[0039] The unsupported organic phase is sulfonated kerosene with P229, wherein the concentration of P229 is 1.0 mol / L.

[0040] The concentrations of rare earth elements in 4N-grade terbium chloride aqueous solution are Sm 0.13 mg / L, Eu 0.31 mg / L, Gd 1.5 mg / L, Tb 156 g / L, Dy 2.3 mg / L, and Ho 0.32 mg / L, respectively.

[0041] SmEuGdTb / TbDyHo full-load fractionation extraction system: the equilibrium organic phase of the feed stage of the SmEuGd / Tb full-load fractionation extraction system is the rare earth saponified organic phase, and the rare earth saponified organic phase enters the SmEuGdTb / TbDyHo full-load fractionation extraction system from the first stage; The terbium chloride aqueous solution is the feed liquid, and the feed liquid 4N-grade terbium chloride aqueous solution enters the SmEuGdTb / TbDyHo full-load fractionation extraction system from the 18th stage (feed stage); the equilibrium water phase of the feed stage of the Tb / DyHo full-load fractionation extraction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com