Gold alloy, preparation method thereof and artificial intelligence processing device

A processing device, gold alloy technology, applied in metal processing equipment, manufacturing tools, metal rolling and other directions, can solve the problems of gold alloy jewelry not resistant to scratches, poor processing performance, not resistant to wear, etc., to achieve the technical effect of increasing hardness , The effect of improving hardness and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] A gold alloy based on Au-Ag-Cu is composed of 5 parts of Au, 58 parts of Ag, 33 parts of Cu, 3 parts of indium, 0.5 parts of vanadium nitride, and 0.5 parts of iron carbide, and does not contain rare earth elements.

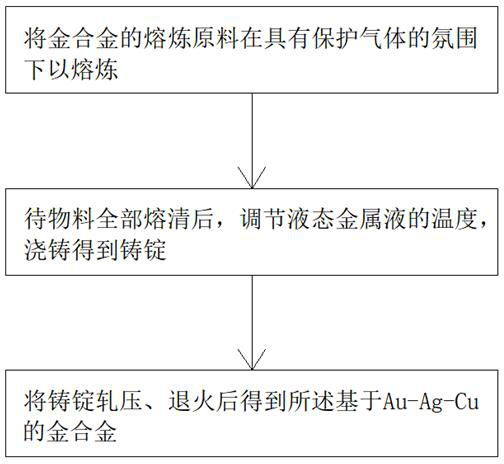

[0090] The preparation method of the Au-Ag-Cu-based gold alloy includes:

[0091] 1). The gold alloy raw material is smelted in the atmosphere with protective gas, and the smelting temperature is 1950℃;

[0092] 2). After the material is completely melted, adjust the temperature of the liquid metal liquid, pour it into the ingot mold groove in turn, and then spray the water to cool the shaping box to obtain the ingot;

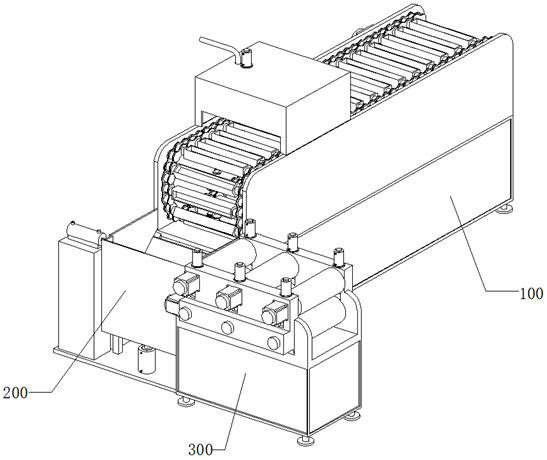

[0093] 3). The ingot is successively rolled and annealed through the rolling roll group mechanism on the ingot bar rolling mill to obtain the gold alloy based on Au-Ag-Cu.

Embodiment 2

[0095] A gold alloy based on Au-Ag-Cu comprises 30 parts of Au, 50 parts of Ag, 15 parts of Cu, 4 parts of indium, 0.01 part of vanadium nitride and 0.01 part of iron carbide in mass percentage, and does not contain rare earth elements.

[0096] The preparation method of the Au-Ag-Cu-based gold alloy includes:

[0097] 1). The gold alloy raw material is smelted in the atmosphere with protective gas, and the smelting temperature is 1950℃;

[0098] 2). After the material is completely melted, adjust the temperature of the liquid metal liquid, pour it into the ingot mold groove in turn, and then spray the water to cool the shaping box to obtain the ingot;

[0099] 3). The ingot is successively rolled and annealed through the rolling roll group mechanism on the ingot bar rolling mill to obtain the gold alloy based on Au-Ag-Cu.

Embodiment 3

[0101] A gold alloy based on Au-Ag-Cu is composed of 25 parts of Au, 41 parts of Ag, 31 parts of Cu, 1.5 parts of indium, 0.7 parts of vanadium nitride, and 0.8 parts of iron carbide in mass percentage, and does not contain rare earth elements.

[0102] The preparation method of the Au-Ag-Cu-based gold alloy includes:

[0103] 1). The gold alloy raw material is smelted in the atmosphere with protective gas, and the smelting temperature is 1950℃;

[0104] 2). After the material is completely melted, adjust the temperature of the liquid metal liquid, pour it into the ingot mold groove in turn, and then spray the water to cool the shaping box to obtain the ingot;

[0105] 3). The ingot is successively rolled and annealed through the rolling roll group mechanism on the ingot bar rolling mill to obtain the gold alloy based on Au-Ag-Cu.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness value | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com