Preparation method of instant porridge rice

A technology for instant porridge and black rice flour, applied in the field of food processing, can solve problems such as loose texture and loss of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a preparation method of instant rice, comprising the following steps:

[0027] 1) twin-screw extrusion granulation is performed on the raw material powder of instant porridge to obtain raw material granules;

[0028] 2) drying the raw material grains to a moisture content of 5% to 15% to obtain instant porridge rice.

[0029] In the present invention, the raw material powder of instant porridge is firstly subjected to twin-screw extrusion granulation to obtain raw material granules. In the present invention, the raw material powder is preferably obtained by pulverizing the raw material of instant porridge rice. In the present invention, the particle size of the raw material powder is preferably 80-100 mesh; the water content of the raw material powder is preferably 20%-45%, more preferably 25%-40%, most preferably 30%-35% %.

[0030] In the present invention, the raw material powder preferably includes one or more of brown rice flour, millet fl...

Embodiment 1

[0042] 1) Crush brown rice into raw powder, pass through an 80-mesh sieve, add water and mix well, and adjust the water content to 30%.

[0043] 2) Utilize a kind of twin-screw extruder (application number: 201510689079.8) for producing miscellaneous grains reconstituted rice, the raw material powder described in step 1) is matured at a die temperature of 70° C. and a screw speed of 200 rpm, and sheared. into rice grains.

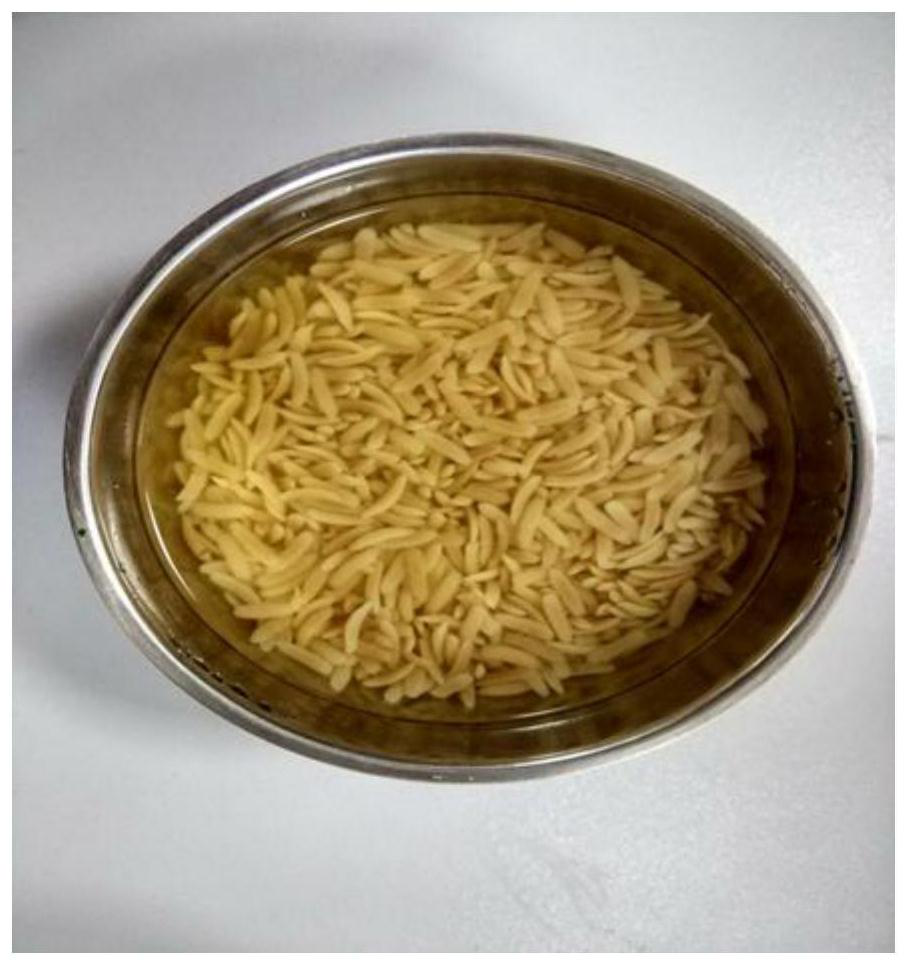

[0044] 3) The granular material described in step 2) is made into instant brown rice with a water content of 5% and a rehydration rate of 415% under the conditions of 160° C. and a drying time of 80 minutes using a tunnel-type hot air dryer, see figure 1 .

[0045] 4) When in use, add 450 mL of hot water at a temperature of 95° C. to 100 g of instant multigrain nutritious rice porridge, soak for 5 minutes to prepare brown rice instant rice porridge with grain aroma, see figure 2 .

Embodiment 2

[0047] 1) Pulverize brown rice and black rice as the main raw materials into powder, pass through a 100-mesh sieve, mix in a ratio of 1:1, add water and mix well, and adjust the water content to 35%.

[0048]2) Utilize a kind of twin-screw extruder (application number: 201510689079.8) for producing miscellaneous grains reconstituted rice, the raw material powder described in step 1) is matured at a die temperature of 70° C. and a screw speed of 225 rpm, and sheared. into rice grains.

[0049] 3) Use the tunnel type hot air dryer to make the granular material described in step 2) under the conditions of 180° C. and drying time of 60min to make instant grain rice with a water content of 8% and a water absorption rate of 420%, see image 3 .

[0050] 4) When in use, add 500 mL of hot water at a temperature of 100° C. to 100 g of instant multigrain nutritious rice porridge, soak for 6 minutes to prepare a rice porridge-like instant rice porridge with grain aroma, see Figure 4 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com