Mortar dry powder and preparation method thereof

A technology for mortar dry powder and sand and gravel, which is applied in the field of mortar dry powder and its preparation, can solve problems such as poor cohesiveness of mortar, and achieve the effects of good moisture resistance and cohesive effect, small weight gain, and not easy to agglomerate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-7

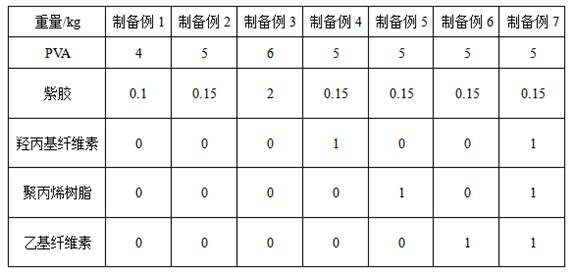

[0043] Weigh PVA, shellac, hydroxypropyl cellulose, polypropylene resin, ethyl cellulose respectively, the specific quality is shown in Table 1, and stir and mix to obtain moisture-proof agents 1-7.

[0044] Table 1 Preparation Example 1-7 Moisture-proofing agent composition

[0045]

[0046] Example of preparation of dispersant

preparation example 8-13

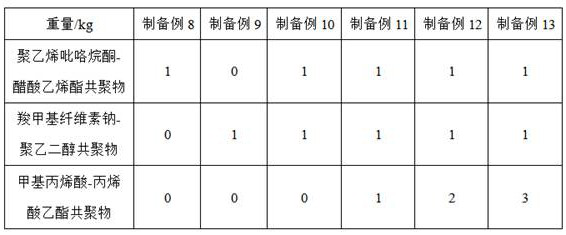

[0048] Weigh the polyvinylpyrrolidone-vinyl acetate copolymer, sodium carboxymethylcellulose-polyethylene glycol copolymer and methacrylic acid-ethyl acrylate copolymer respectively, the specific quality is shown in Table 2, stir and mix to obtain dispersant 1 -6.

[0049] Table 2 Preparation Example 8-13 Dispersant Composition

[0050]

[0051] Preparation example of dispersion-modified moisture-proofing agent

preparation example 14

[0053] The dispersing agent 1 and the moisture-proofing agent 1 are stirred and mixed to obtain the dispersion-modified moisture-proofing agent 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com