Method for enhancing microalgae carbon sequestration and oil production by using diethanol amine

A diethanolamine, microalgae technology, applied in microorganism-based methods, biochemical equipment and methods, with the addition of compounds to stimulate growth, etc., can solve the lack of stimulating lipid content, slow mass transfer, high oil content and It is difficult to obtain high oil yield at the same time, so as to achieve the effect of increasing the oil content of the cell, increasing the final yield, and promoting the metabolism of oil production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

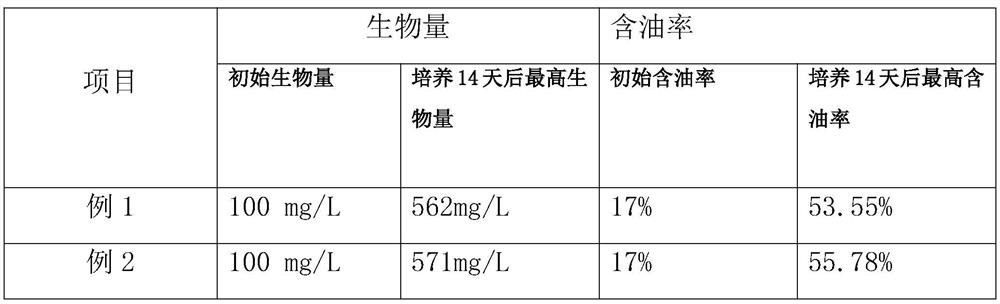

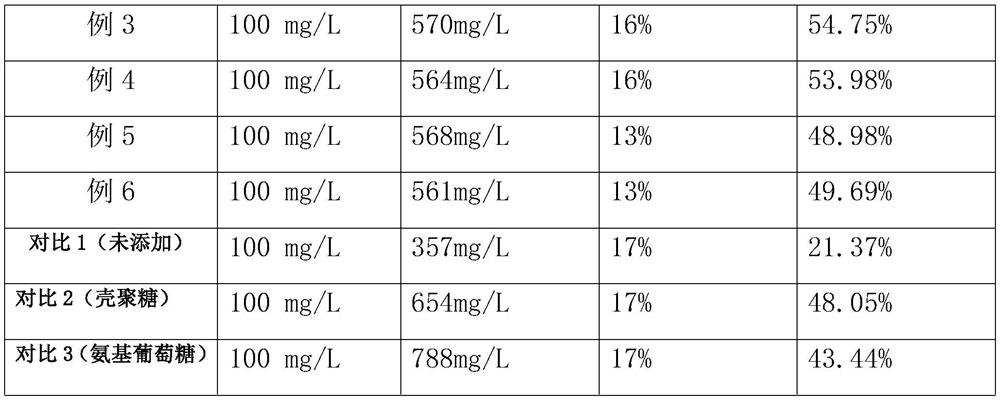

[0022] Example 1

[0023] The method for enhancing carbon fixation and oil production of microalgae by using diethanolamine in this embodiment includes the following steps: adding 1 mg / L of diethanolamine to the BG11 medium, and then inoculating the Chlorella in the logarithmic growth phase according to the initial inoculation concentration of about 1 mg / L. The microalgae solution was prepared by inoculating 100mg / L in nutrient-rich BG11 medium. The initial pH value of the microalgae solution was 6.5, the culture temperature was 25°C, the light intensity was 4000Lux, and the light cycle was 12h:12h (light: dark) , 3% CO was introduced into the microalgae liquid culture 2 , the air supply rate was 20mL / min and the aeration stone was used for aeration, which lasted for 12h, and the culture period was 14 days. During the culture process, the biomass of Chlorella was measured every day.

Example Embodiment

[0024] Embodiment 2

[0025] The method for enhancing carbon fixation and oil production of microalgae by using diethanolamine in this embodiment includes the following steps: adding 5 mg / L of diethanolamine to the SE medium, and then chlorella in logarithmic growth phase according to the initial inoculation concentration of 100mg / L was inoculated into nutrient-rich SE medium to obtain microalgae solution. The initial pH value of the microalgae solution was 7.5, the culture temperature was 35°C, the light intensity was 4000Lux, and the light cycle was 12h:12h (light: dark), Bubble 15% CO during microalgae culture 2 , the air supply rate was 12mL / min and the aeration stone was used for aeration, which lasted for 2h, and the culture period was 14 days. During the culture process, the biomass of Chlorella was measured every day.

Example Embodiment

[0026] Embodiment 3

[0027] The method for enhancing carbon fixation and oil production of microalgae by using diethanolamine in this embodiment includes the following steps: adding 2 mg / L of diethanolamine to SE medium, and then setting the initial inoculation concentration of Scenedesmus in logarithmic growth phase to 200 mg according to the initial inoculation concentration. / L was inoculated into nutrient-rich SE medium to obtain microalgae solution. The initial pH value of the microalgae solution was 7.5, the culture temperature was 35°C, the light intensity was 6000 lux, and the light cycle was 12h:12h (light: dark). Introduce 15% CO during microalgae culture 2 , the air supply rate was 45mL / min and the aeration stone was used for aeration, which lasted for 12h, and the culture period was 14 days. During the culture process, the biomass of Scenedesmus was measured every day.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap