Formula and method for improving pore distribution and qi holding capacity of steamed rice sponge cake

A technology for rice cakes and pores, which is applied in the field of food processing, can solve the problems that affect the comprehensive quality of rice cakes, the size of pores is different, the sensory score is reduced, etc., so as to improve the gas production capacity and gas holding capacity, uniform distribution, and increase the sensory score. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

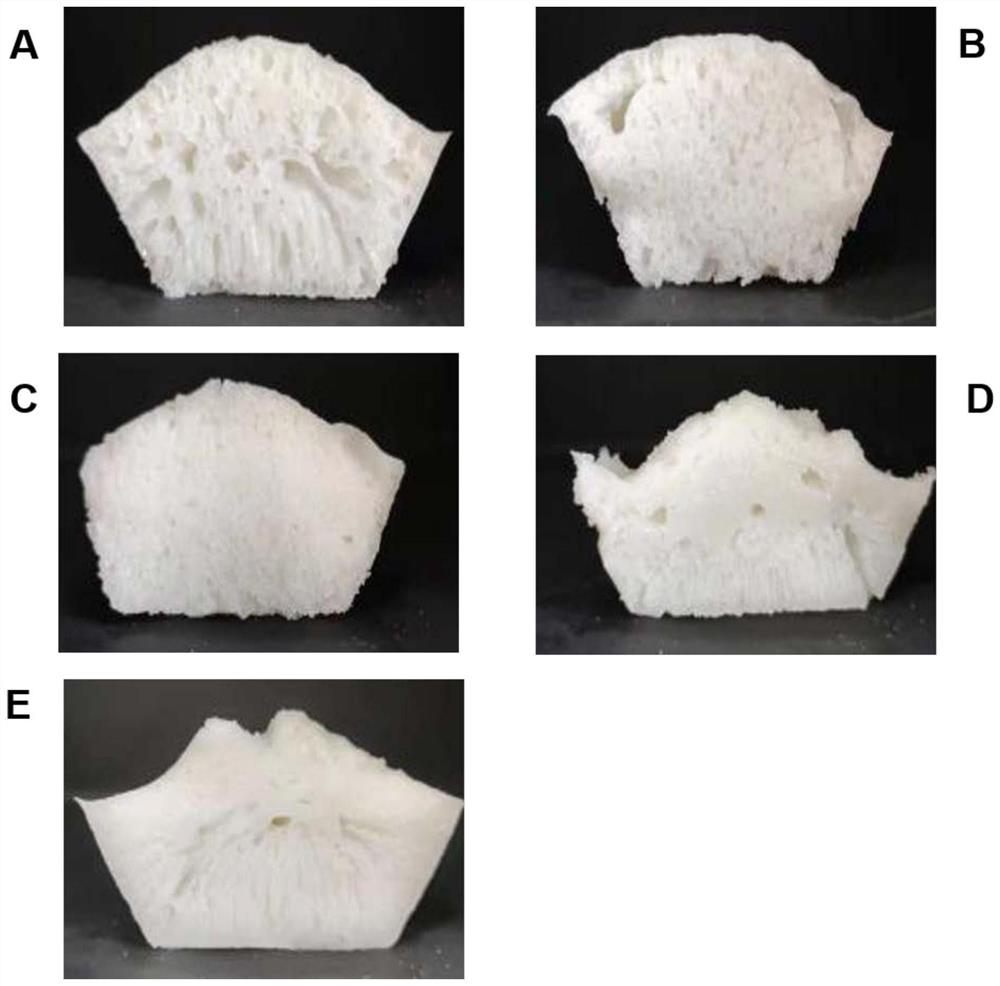

[0053] Example 1 The effect of refining water temperature on the pores of rice cakes

[0054] The formula and method for improving the porosity distribution and gas holding capacity of rice cake, comprising the following steps:

[0055] (1) material selection: select japonica rice, after mixing according to the ratio of japonica rice and water mass volume ratio 200g:300mL, soak in water temperature 28 ℃ for 4 hours, with the purpose of fully soaking the rice;

[0056] (2) Lactic acid bacteria fermentation: press 1.8×10 into the soaked rice water in step (1). 6 The ratio of cfu / mL was added to the lactic acid bacteria liquid and then fermented and cultured at 26°C for 24h;

[0057] (3) Refining: Drain the water in step (2), rinse twice with tap water, drain, mix 100 g of wet rice, 8 g of soft white sugar, and 200 mL of warm water in proportion, and refine in a refiner for 2 minutes to obtain Homogeneous rice milk.

[0058] (4) Yeast fermentation: Add yeast to the rice milk o...

Embodiment 2

[0070] Example 2 The effect of fermentation sequence on the pores of rice cake

[0071] 2.1 Using lactic acid bacteria first and then yeast fermentation to make rice cakes, including the following steps:

[0072] (1) Material selection: select japonica rice, mix at a ratio of 200g:300mL of rice to water mass and volume, soak for 4 hours at a water temperature of 28°C, and fully soak the rice for the purpose;

[0073] (2) Lactic acid bacteria fermentation: press 1.8×10 into the soaked rice water in step (1). 6 cfu / mL, fermented and cultured at 26°C for 24h after inserting the lactic acid bacteria liquid;

[0074] (3) Refining: Drain the water in step (2), rinse twice with tap water, drain, and mix 100 g of wet rice, 8 g of soft white sugar, and 200 mL of warm water according to the proportion, and the temperature of the warm water is 30 ℃, and grind in a refiner. slurry for 2 minutes to obtain a homogeneous rice slurry.

[0075] (4) Yeast fermentation: add yeast to the rice ...

Embodiment 3

[0100] Embodiment 3 The influence of lactic acid bacteria fermentation temperature on the pores of rice cake

[0101] The formula and method for improving the porosity distribution and gas holding capacity of rice cake, comprising the following steps:

[0102] (1) Material selection: select japonica rice, mix it according to the ratio of japonica rice and water mass-volume ratio of 200g:300mL, soak for 4 hours at a water temperature of 28°C, and fully soak the rice for the purpose;

[0103] (2) Lactic acid bacteria fermentation: press 1.8×10 into the soaked rice water in step (1). 6 cfu / mL was fermented and cultured for 24h after adding lactic acid bacteria liquid;

[0104] (3) Refining: Drain the water in step (2), rinse twice with tap water, drain, and mix 100 g of wet rice, 8 g of soft white sugar, and 200 mL of warm water according to the proportion, and the temperature of the warm water is 30 ℃. The slurry was refined for 2 minutes to obtain a homogeneous rice slurry. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com