Extreme manufacturing equipment of micro-droplet three-dimensional sphere structure and use method

A technology for manufacturing equipment and microdroplets, which is applied in the field of extreme manufacturing equipment for microdroplet three-dimensional spherical structures, and can solve problems such as restricting application development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

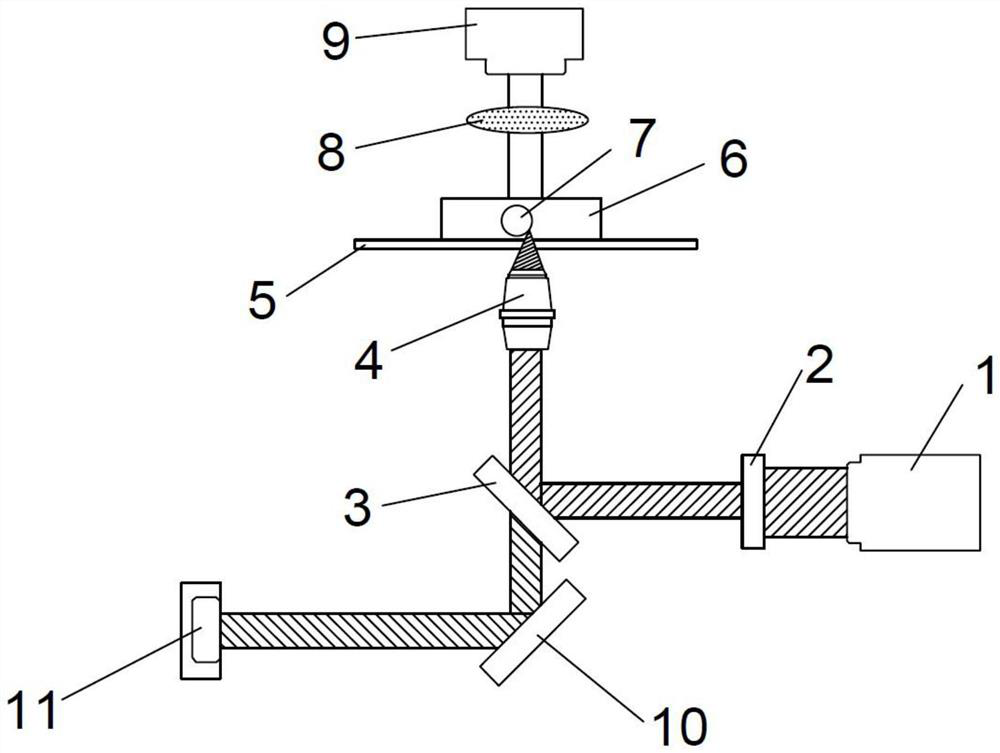

[0039] Refer to the attached figure 1 , 2 As shown, an extreme manufacturing equipment for a three-dimensional spherical structure of droplets includes a laser micro-nano processing system, a microfluidic chip system 6, and a real-time observation system. The laser micro-nano processing system includes a tunable laser 1, an aperture diaphragm 2 , a dichroic mirror 3 and an electrically controlled translation stage 5, the aperture stop 2 is arranged on the left side of the tunable laser 1, the dichroic mirror 3 is arranged on the left side of the aperture stop 2, and the electrical The controlled translation stage 5 is arranged above the dichroic mirror 3 , the microfluidic chip system 6 is arranged on the electronically controlled translation stage 5 , and the soft matter droplets are located in the microfluidic chip system 6 . The real-time observation system includes a light source subsystem and a camera subsystem, the light source subsystem is arranged above the microfluid...

Embodiment 2

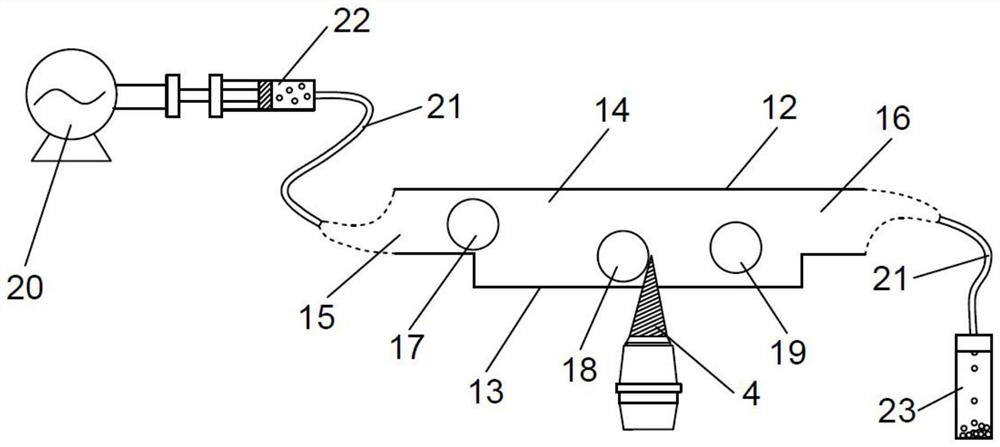

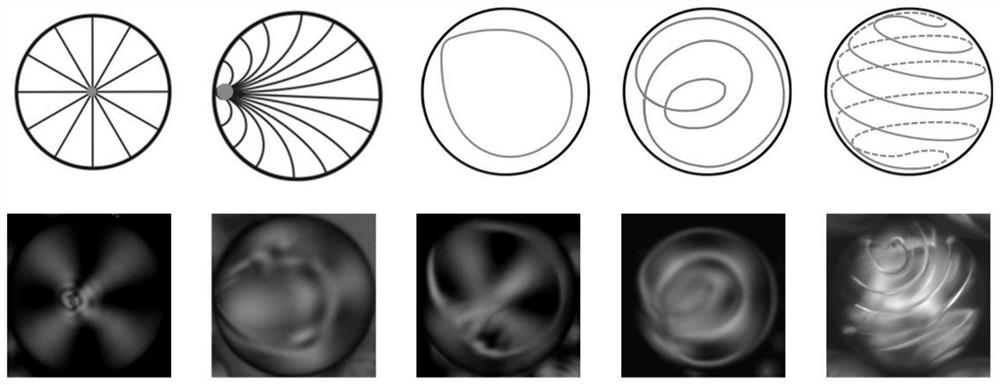

[0045] Refer to the attached figure 1 , 2 3, 4, and 6, a method for assembling droplet spheres with topological lines in soft matter droplets, comprising the following steps:

[0046] Step 1: The material of the soft substance droplets is doped with different concentrations of R811 (4-(4-hexyloxybenzoyloxy)benzoic acid-R-(+)-2-octyl ester, liquid crystal chiral additive) (Sigma-Aldrich) E7 (Merck) liquid crystal, target droplet 7, through the microfluidic peristaltic syringe pump 20 to control the syringe 22 to send the aqueous solution containing the target droplet 7 into the microfluidic chip 6 for processing, and then tunable The laser 1 emits a large-diameter continuous laser beam, and after being focused by the aperture diaphragm 2, the dichroic mirror 3 and the microscope objective lens 4, a small-diameter laser spot is obtained, and the typical spot diameter is 5 microns;

[0047] Step 2: hit the focused laser spot to the boundary of the target droplet 7 of the interl...

Embodiment 3

[0054] Refer to the attached figure 1 , 2 , 3, 5, and 6, a method for assembling droplet spheres from topological lines in soft matter droplets. The difference from Embodiment 2 is that in this Embodiment 3, in step 1, the target droplet 7 is doped with 0.05wt% R811 (4-(4-hexyloxybenzoyloxy)benzoic acid-R-(+)-2-octyl ester, liquid crystal chiral additive), when the doping concentration reaches a steady state, it is the target soft matter droplet Two 30, and the topological structure is a topological point 31, the aqueous solution in the third step is doped with 0.2wt% surfactant SDS (sodium dodecyl sulfate), SDS (sodium dodecyl sulfate) can make the target Stable suspension of Soft Matter Droplet II 30 in water.

[0055] The E7 liquid crystal is doped with an endothermic material (coumarin-6) of 0.1 wt%, and the laser spot can be observed when the laser spot is working in the laser working area.

[0056] In the third step, when the laser exposure is 5 s, the aqueous solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com