CuO/g-C3N4 photocatalyst as well as preparation method and application thereof

A photocatalyst, g-c3n4 technology, applied in metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, peroxide/peroxyhydrate/peroxyacid/superoxide/ozonide Orientation can solve the problem of low yield and achieve the effect of high yield and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

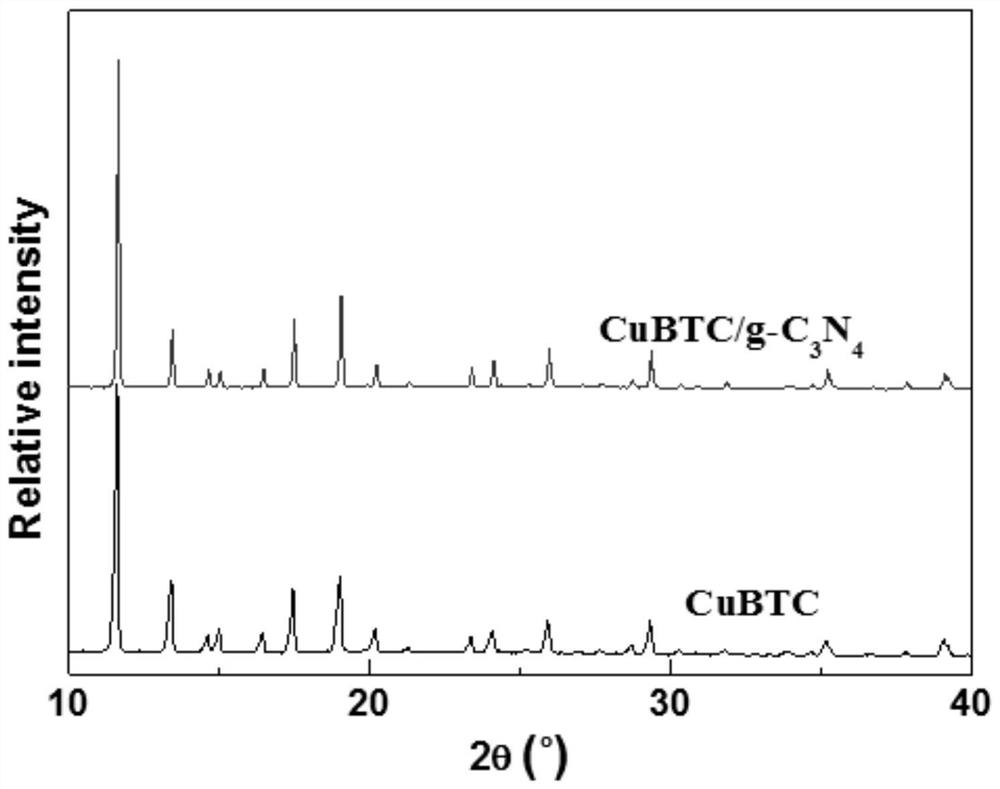

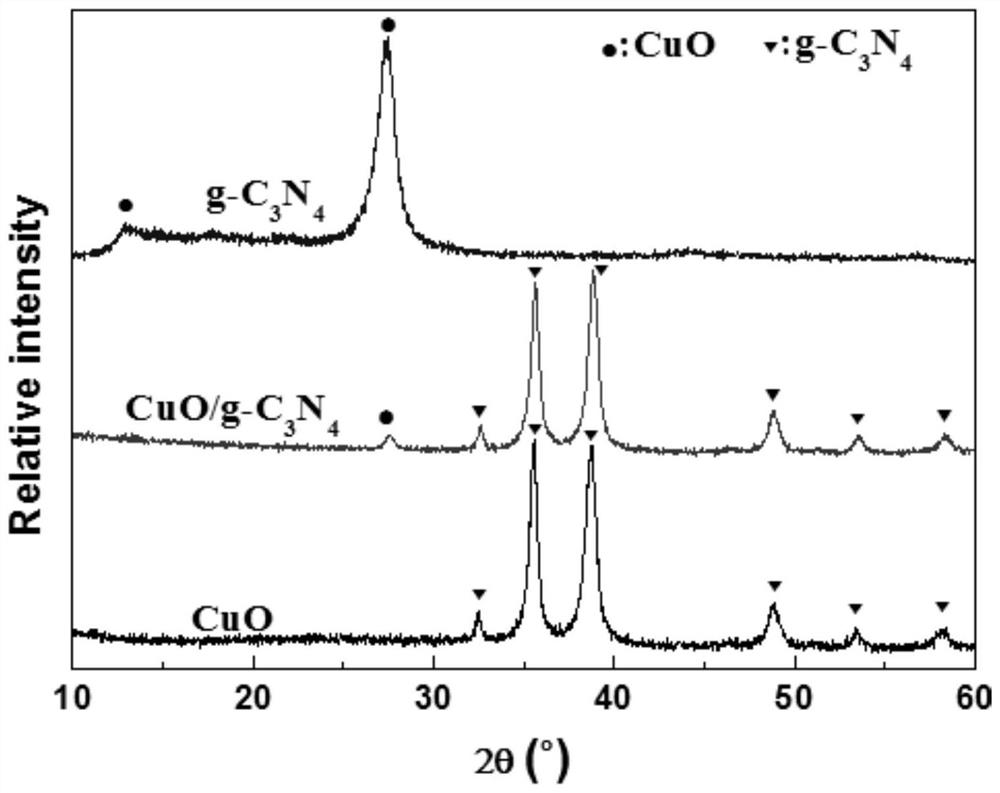

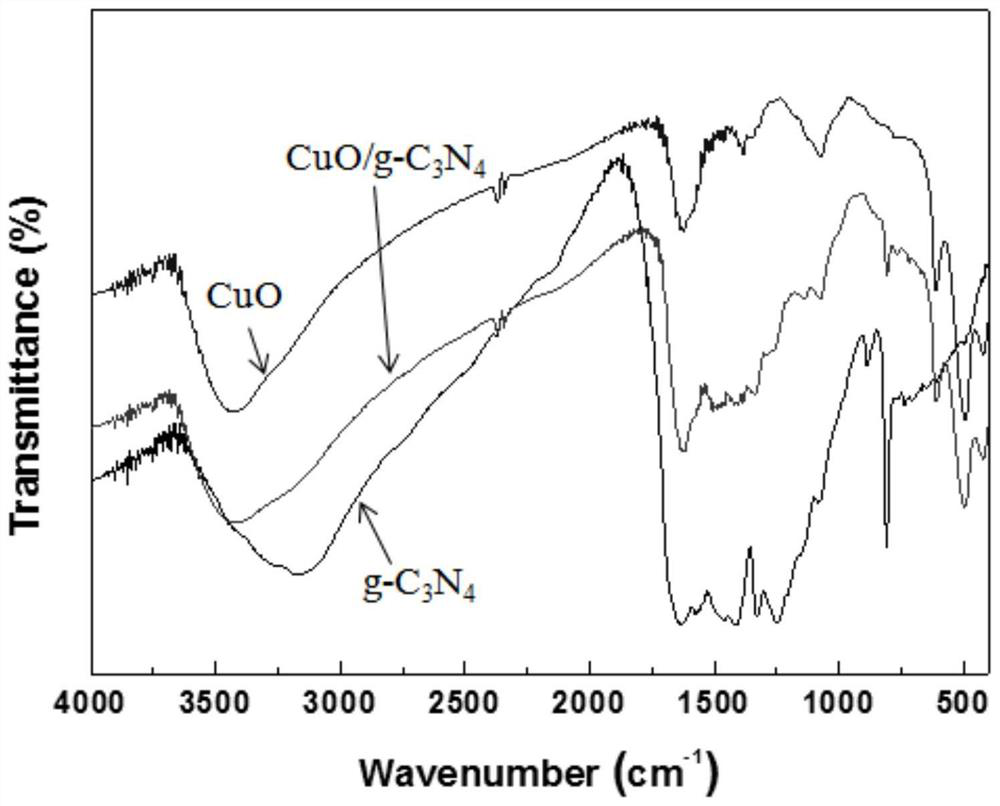

[0028] Put 0.028g of g-C 3 N 4 Add to the mixed solution consisting of 3mL N,N dimethylformamide, 4mL ethanol and 2mL pure water, ultrasonicate for 1h, then add 0.438g anhydrous copper nitrate and 0.236g trimesic acid in turn, stir until completely dissolved to obtain the reaction solution. The reaction solution was transferred into a polytetrafluoroethylene hydrothermal kettle, sealed, and kept at 85°C for 24 hours for a hydrothermal reaction. After the reaction was completed, it was cooled to room temperature, and the precipitate A obtained by the reaction was treated with N,N dimethylformamide and Alternately washed with ethanol, and then dried at 60 °C for 6 h to obtain 0.4 g of precipitate A, which is CuBTC / g-C 3 N 4 . The dried precipitate A was ultrasonically dispersed into 40 ml of distilled water, 1.6 g of sodium hydroxide was added, and stirred for 2 h. The obtained precipitate B was washed with pure water and dried at 60 °C for 6 h. The obtained powder was CuO / g...

Embodiment 2

[0035] Put 0.028g of g-C 3 N 4 Add to the mixed solution consisting of 4mL N,N dimethylformamide, 6mL ethanol and 2mL pure water, ultrasonicate for 1h, then add 0.876g anhydrous copper nitrate and 0.472g trimesic acid in turn, stir until completely dissolved to obtain the reaction solution. The reaction solution was transferred into a polytetrafluoroethylene hydrothermal kettle, sealed, and kept at 70°C for 36 hours for hydrothermal reaction. After the reaction was completed, it was cooled to room temperature, and the precipitate A obtained by the reaction was treated with N,N dimethylformamide and Alternately washed with ethanol, and then dried at 70 °C for 5 h to obtain 0.8 g of precipitate A, which is CuBTC / g-C 3 N 4 . The dried precipitate A was ultrasonically dispersed into 40 ml of distilled water, 3.2 g of sodium hydroxide was added, and stirred for 1 h. The obtained precipitate B was washed with pure water and dried at 40 °C for 6 h. The obtained powder was CuO / g-C...

Embodiment 3

[0039] Put 0.056g of g-C 3 N 4 Add to the mixed solution consisting of 5mL N,N dimethylformamide, 3mL ethanol and 1.5mL pure water, ultrasonicate for 1h, then add 0.438g anhydrous copper nitrate and 0.236g trimesic acid in turn, stir until completely dissolved to obtain reaction solution. The reaction solution was transferred into a polytetrafluoroethylene hydrothermal kettle, sealed, and kept at 100 ° C for 12 hours for hydrothermal reaction. After the reaction was completed, it was cooled to room temperature, and the precipitate A obtained by the reaction was treated with N,N dimethylformamide and Alternately washed with ethanol, and then dried at 50 °C for 7 h to obtain 0.41 g of precipitate A, which is CuBTC / g-C 3 N 4 . The dried precipitate A was ultrasonically dispersed into 40 ml of distilled water, 2.0 g of sodium hydroxide was added, and stirred for 5 h. The obtained precipitate B was washed with pure water and dried at 70 °C for 6 h. The obtained powder was CuO / g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com